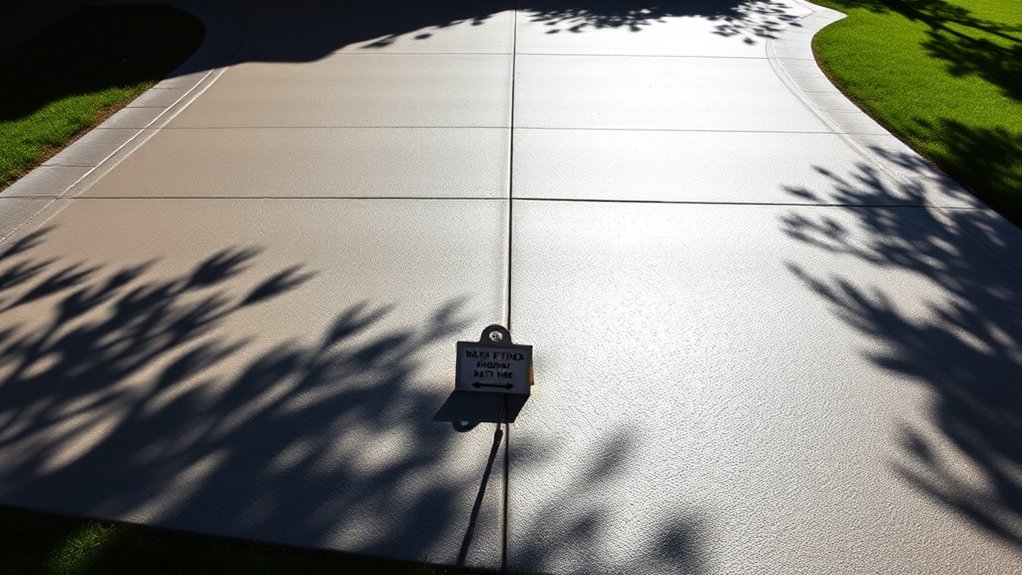

You should wait at least 7 days before driving on your new concrete driveway. This allows the concrete to cure properly and reach about 70% strength, which is sufficient for light vehicle traffic. Driving on it too soon can weaken the surface, leading to cracks and damage. To ensure durability, keep an eye on moisture levels and avoid heavy loads until the concrete has achieved maximum strength, which typically takes 28 days. For more insights on curing practices, continue reading.

Table of Contents

ToggleKey Takeaways

- Wait at least 7 days before allowing light vehicles on a new concrete driveway.

- For heavier vehicles, give it up to 30 days to ensure it reaches full strength.

- Make sure all bleed water has evaporated before using the surface.

- Regularly check the driveway for dryness and hardness to avoid damage from early use.

- Protect the curing concrete from direct sunlight and extreme temperatures during the initial curing period.

Understanding Concrete Curing Times

Understanding concrete curing times is crucial for the longevity and durability of your new driveway. The curing process is vital for hydration, which strengthens the concrete. You can walk on the surface after 24-48 hours, but adding weight too soon may cause surface damage. After about 7 days, the concrete reaches around 70% of its strength, making it suitable for light vehicle traffic. However, it takes a full 28 days to achieve maximum strength, which is around 90-100%. During this period, it’s important to maintain proper moisture and temperature to avoid issues like cracking and dusting. Proper curing protects the investment in the driveway and prevents future maintenance issues. Ignoring these factors can result in weak, brittle concrete, compromising your driveway’s integrity and lifespan.

Factors Affecting Concrete Curing Duration

Several factors significantly affect the duration of concrete curing, which in turn influences the strength and durability of your driveway.

Curing temperature is crucial; high temperatures can speed up hydration but also raise the risk of cracking if moisture isn’t managed properly. On the other hand, low temperatures slow the curing process, so heating measures may be necessary to ensure complete curing. Additionally, curing retains moisture in concrete during hardening, which is vital for achieving optimal strength.

Humidity levels also play a role. Higher humidity can aid in moisture retention, promoting faster curing, while low humidity can lead to rapid surface drying, risking the integrity of the concrete. Wind can further exacerbate evaporation rates, increasing the likelihood of surface cracks.

The composition of the concrete mix, including the type of cement used and the water-to-cement ratio, also impacts strength development. Thicker slabs tend to retain heat longer, which can extend curing time, while larger pours require careful moisture control due to the potential for uneven drying.

Understanding these factors is essential for achieving optimal curing results.

The Importance of Proper Curing

Proper curing is essential for the strength and durability of your concrete driveway, as it greatly affects the hydration of the cement. Effective curing methods help retain moisture, which is vital for the ongoing hydration of cement particles. Without adequate moisture, concrete can dry out too quickly, resulting in weak surfaces and a higher risk of cracking. In the first week, concrete achieves around 70% of its strength, but this requires consistent moisture. Concrete curing develops structural integrity, making it crucial to manage moisture effectively. Poor curing can lead to surface dusting and crazing, which can undermine both appearance and structural integrity. By carefully managing moisture during the curing period, you enhance the driveway’s durability and resistance to environmental factors, ensuring it lasts for years to come and protecting your investment.

Recommended Curing Practices

To ensure your new concrete driveway is strong and durable, effective curing practices are crucial. Start by keeping the concrete moist using methods such as wet burlap, plastic sheeting, or regular misting, especially in hot or windy weather.

Apply curing compounds immediately after finishing to lock in moisture, ensuring they’re suitable for your driveway’s intended use. Follow the manufacturer’s instructions for the best application rates and timing.

It’s important to protect the curing concrete from direct sunlight and extreme temperatures to prevent cracking. Aim for a minimum of 7 days of moist curing to achieve significant strength, extending this to 28 days if necessary, particularly for thicker slabs.

Following these practices will help your driveway reach its full potential.

Early Use Precautions for New Concrete

After ensuring proper curing practices, it’s important to consider the early use of your new concrete driveway.

To protect the surface and prevent damage from early traffic, follow these guidelines:

- Wait at least 7 days before allowing light vehicles; for heavier vehicles, wait up to 30 days.

- Ensure all bleed water has evaporated before permitting any traffic.

- Keep pets and sharp objects off the surface, as they can cause scratches or dents.

- Check the surface for dryness and hardness before use.

Using the driveway too soon can weaken its structure, resulting in cracks and unsightly markings.

Seasonal Considerations Impacting Curing

As seasonal temperatures vary, they significantly affect the curing process of concrete driveways, making it crucial to recognise how these changes influence strength development.

Cold weather can slow down hydration and pose a risk of freezing, which may weaken the concrete. Conversely, hot conditions can accelerate evaporation, increasing the likelihood of surface cracking if moisture isn’t properly managed.

Generally, temperatures above 10°C (50°F) support normal curing, while cooler conditions require protective measures like insulated blankets.

High humidity during warmer months can help with curing, but dry, windy weather can lead to excessive evaporation, necessitating additional moisture management.

Adapting your approach to these temperature influences is essential for achieving optimal curing and ensuring the long-term durability of your concrete driveway.

Concrete Mix Design and Curing

When designing your concrete mix, it’s important to consider how its composition affects curing time and strength development.

The choice of additives, such as accelerators or retarders, can significantly influence the curing process depending on environmental conditions. For instance, using an accelerator can be beneficial in colder weather, while a retarder might be more suitable in hot conditions to prevent rapid drying.

Furthermore, the thickness of the slab is crucial for moisture retention, which is vital for proper hydration and long-term durability.

Mix Composition Impact

Understanding how the composition of concrete mix affects curing is vital for achieving optimal strength and durability in new driveways.

Different types of mixes result in varied strength developments and curing times. Here are some key factors to consider:

- Cement Type: High early-strength cement allows for quicker use, whereas sulphate-resistant mixes typically require longer curing times.

- Water-Cement Ratio: A lower ratio produces denser, stronger concrete.

- Aggregate Quality: Well-graded aggregates contribute to better density and overall strength of the mix.

- Supplementary Materials: Additives like fly ash may delay initial strength gains but enhance long-term durability.

Additives and Curing

The incorporation of additives in concrete mixes significantly affects the curing process, improving both strength and durability. Various types of additives can enhance curing efficiency, tailored to environmental conditions and specific project needs.

| Additive Type | Purpose | Impact on Curing |

|---|---|---|

| Accelerators | Speed up hydration | Shortens time to achieve strength |

| Retarders | Delay setting time | Helps prevent thermal cracking |

| Curing Compounds | Create a moisture-retaining layer | Reduces evaporation |

| Water Reducers | Decrease water-to-cement ratio | Enhances strength and workability |

Using these additives correctly can lead to better concrete performance, especially in challenging climates or complex construction projects.

Thickness Considerations

Concrete thickness is crucial for the durability and performance of a driveway. The right thickness affects load-bearing capacity, which varies with vehicle types and soil conditions.

Here are some key points to consider:

- Residential driveways: Typically 10 to 15 cm (4 to 6 inches) for light vehicles, and 12 to 15 cm (5 to 6 inches) for heavier loads.

- Commercial driveways: Require a thickness of 15 to 30 cm (6 to 12 inches) to handle heavy traffic effectively.

- Soil type: On unstable soils, thicker slabs are essential to prevent cracking.

- Environmental factors: Thicker designs are better suited to endure freeze-thaw cycles and moisture stress.

Choosing the right thickness, along with a suitable concrete mix, will significantly enhance the longevity and reliability of your driveway.

Monitoring Curing Progress

Monitoring curing progress is essential for ensuring the durability and strength of your new driveway. Regularly checking moisture levels helps prevent premature drying and surface cracking.

Use effective curing methods like sealants or curing compounds to retain moisture. Be mindful of environmental factors such as temperature and humidity; for example, high temperatures can lead to increased evaporation, while high humidity helps keep moisture in.

Keep an eye on the concrete surface for signs of distress, like crazing or dusting, which may indicate poor curing.

Expert Recommendations for Safe Use

While your new concrete driveway cures, it’s important to follow some key guidelines to ensure safe use and longevity.

Here’s what you need to keep in mind:

- Avoid driving light vehicles for at least 7 days to achieve around 70% strength.

- Steer clear of heavy vehicles for 28 days to allow for full curing.

- Be mindful of weather conditions; warmer temperatures help the curing process, whereas colder weather can hinder it.

- Take extra care around the edges, as they cure more slowly and require additional attention.

Frequently Asked Questions

Can I Park My Car on New Concrete After One Week?

Yes, you can park your car on new concrete after a week, as it usually achieves around 70% of its strength by then. Just be sure to follow parking guidelines to protect the edges and maintain the surface’s integrity. For instance, avoid sharp turns or heavy loads that could cause damage.

What Happens if I Drive on Concrete Too Soon?

Driving on concrete too soon is like treading on a fragile flower; it can cause damage such as cracks, surface pitting, and lasting weakness. It’s best to wait until the concrete has fully cured to ensure its durability and safety.

How Can I Tell if My Concrete Is Fully Cured?

To tell if your concrete is fully cured, look for a consistent colour, firmness when pressed, sharp edges, and no visible cracks. Ensure it has achieved adequate strength, usually within 28 days, for optimal durability.

Does Rain Affect the Curing Process of New Concrete?

Rain can interfere with the curing process of new concrete, potentially causing dilution on the surface and leading to erosion. If rainwater pools, you may end up with weak spots and an uneven texture. It’s vital to cover the concrete with tarps to ensure it cures properly and maintains its strength.

Can I Use a Sealant on the Driveway Before 28 Days?

You shouldn’t apply sealant to your driveway before 28 days. Doing so can trap moisture, affect adhesion, and reduce the sealant’s effectiveness. Waiting the full curing time ensures optimal performance and durability for your driveway.

Conclusion

In summary, it’s crucial to pay attention to curing conditions for concrete’s strength and stability. By following proper practices and allowing the recommended curing time, you can ensure your driveway is durable and reliable. Rushing the process can lead to issues down the line, so be patient and let the concrete cure fully before driving on it. Factors like seasonal changes and specific mix designs also influence curing time. A well-cured driveway will provide a solid surface for years to come.

Just how long can you expect your tarmac driveway to last? Discover key factors and maintenance tips that can extend Read more

Begin your journey to a pristine tarmac driveway with essential annual maintenance tips that could save you costly repairs later. Read more

Explore the pros and cons of pressure washing a tarmac driveway and discover essential tips to avoid costly mistakes that Read more