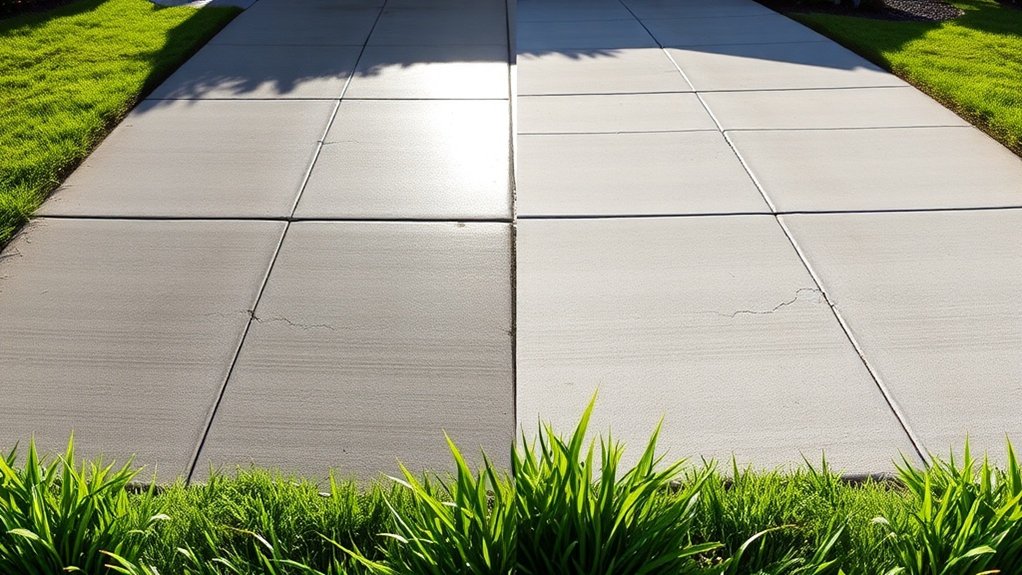

Using fibre reinforcement in your concrete driveway is a wise decision that can significantly enhance its durability and resistance to cracking. The fibres help to evenly distribute stresses, which reduces the likelihood of serious cracking and improves impact resistance. This means your driveway will be better equipped to handle heavy vehicles and tough weather conditions over time. Additionally, it simplifies the installation process and requires less maintenance. If you’re keen to learn more about the specific benefits and types of fibres that are most effective, there’s plenty to discover.

Table of Contents

ToggleKey Takeaways

- Fibre reinforcement improves crack resistance, meaning less maintenance and a longer lifespan for concrete driveways.

- It boosts impact and fatigue resistance, making driveways more durable under heavy vehicle loads, such as those from vans or SUVs.

- Fibre-reinforced concrete allows for quicker installation with pre-mixed materials, reducing both labour and handling time.

- Enhanced durability means less frequent repairs, ultimately saving you money in the long run.

- Using fibre reinforcement is particularly advantageous for driveways with unique shapes, offering strength without adding extra weight.

What Is Fiber Reinforcement?

Fiber reinforcement in concrete is a technique that improves the material’s strength and durability by adding short, discrete fibres. These fibres can be synthetic, natural, glass, or steel, and act as secondary reinforcement, helping to minimise cracking caused by shrinkage and temperature changes. Choosing the right fibres involves understanding their characteristics, such as aspect ratio and shape. Since the fibres are randomly oriented, they help distribute internal stresses more evenly, reducing the likelihood of cracks forming and spreading. While they don’t significantly boost tensile strength, they’re crucial for enhancing toughness and resistance to impact. By bridging cracks and limiting their width, fibre reinforcement enhances the overall performance of concrete. This makes it ideal for various applications, such as driveways and floor slabs, particularly because it helps reduce cracking and increases energy absorption.

Types of Fiber Used in Concrete

When choosing the right reinforcement for concrete, it’s essential to know the different types of fibres available, as each offers distinct advantages.

Steel fibres, classified under ASTM A820, are known for their high tensile strength, making them ideal for demanding applications like road surfaces and industrial flooring.

Glass fibres, identified as Type II fibres, not only enhance the aesthetic appeal but also improve durability, making them suitable for architectural features.

Synthetic fibres, classified as Type III, come in both micro and macro options. They help control cracking and boost impact resistance, commonly used in pavements and driveways. Additionally, SikaFiber® technology can enhance energy absorption and fire resistance, further increasing the longevity of the concrete.

Natural fibres, classified as Type IV, provide an eco-friendly alternative but are generally weaker.

Benefits of Fiber Reinforcement

Many people underestimate the importance of fibre reinforcement in concrete driveways, but its benefits are significant. Fibre reinforcement boosts durability, helps control crack widths, and reduces water penetration, which means less maintenance and fewer repairs over time. This contributes to a more sustainable driveway. Additionally, macro synthetic fibers enhance crack resistance by bridging cracks with surrounding fibers, providing increased tensile strength and flexibility.

Furthermore, fibre-reinforced concrete offers design flexibility, adapting well to different load conditions and soil movements without losing strength. It also has better impact and fatigue resistance, making it ideal for heavy vehicle traffic. Using fibres in concrete can streamline the construction process, cutting down on labour costs and time.

Enhanced Crack Resistance

Using fibre reinforcement in your concrete driveway significantly improves its resistance to cracking.

The fibres create a network that helps prevent cracks from forming and spreading, ensuring the long-term strength of the surface.

This smart choice not only enhances durability but also reduces the need for maintenance throughout the driveway’s life.

Crack Prevention Mechanisms

Incorporating fibre reinforcement significantly improves crack resistance in concrete driveways through several effective mechanisms. The even distribution of fibres throughout the concrete helps prevent crack growth and stabilises smaller cracks. Microfibres are particularly effective in reducing early-stage plastic shrinkage cracking, while macrofibres provide toughness by holding crack edges together under tension. This combination reduces crack sizes, thereby limiting the entry of corrosive agents.

| Mechanism | Description |

|---|---|

| Fibre Intersection | Prevents the growth of developing cracks |

| Microfibre Action | Minimises plastic shrinkage cracking |

| Macrofibre Support | Keeps crack edges together under tension |

| Uniform Distribution | Ensures consistent reinforcement against cracking |

| Crack Size Reduction | Restricts access for corrosive agents |

Enhanced Durability Benefits

Enhanced durability in concrete driveways is mainly achieved through the use of fibre reinforcement, which significantly reduces both the frequency and width of cracks.

By distributing stress at a micro level, fibres can decrease crack widths by 30% to 50% compared to standard concrete. This not only helps prevent shrinkage cracks during the curing process but also strengthens the driveway against environmental stresses.

Smaller cracks reduce water and chemical penetration, promoting sustainability by lowering long-term repair costs. Furthermore, fibre reinforcement enhances the visual appeal of decorative driveways, ensuring a consistent surface finish.

Long-Term Structural Integrity

Incorporating fibre reinforcement not only enhances durability but also plays a crucial role in ensuring the long-term structural integrity of concrete driveways.

The even distribution of fibres within the concrete mix improves crack resistance by bridging microcracks, which helps prevent them from widening under varying loads. This added tensile strength allows the concrete to absorb deformation, delaying the onset and growth of cracks over time.

Additionally, fibre reinforcement helps reduce explosive spalling and boosts impact resistance, significantly extending the lifespan of your driveway.

With fewer microcracks, permeability is reduced, limiting the entry of harmful substances that could corrode any embedded steel.

Ultimately, this robust approach ensures your driveway can withstand daily use, maintaining its structural performance for many years.

Improved Strength and Impact Resistance

Incorporating fibre reinforcement into your concrete driveway significantly boosts its strength and resistance to impact.

This reinforcement enhances the driveway’s ability to withstand repeated loading, ultimately prolonging its lifespan.

By bridging microcracks, fibres help prevent the spread of cracks, ensuring your driveway remains robust enough to handle heavy vehicles.

For instance, if you regularly park a large van, this added durability can make a real difference in keeping your surface intact.

Enhanced Tensile Strength

Enhanced Tensile Strength of Concrete Driveways

Adding fibre reinforcement significantly increases the tensile strength of concrete driveways, making them more resistant to stress and impact. This improvement is largely due to effective fibre bonding, which enhances the concrete’s ability to withstand tension.

Here are four key benefits:

- Increased Load-Bearing: Fibres help bridge cracks, allowing for better distribution of loads after a crack occurs.

- Enhanced Durability: Fibre-reinforced concrete can withstand tensile stresses, lowering the chances of sudden failure.

- Optimised Fibre Length: The right fibre size ensures efficient embedding, promoting effective transfer of tensile strength.

- Improved Crack Interception: A higher number of fibres intercept cracks more efficiently than traditional rebar, helping to maintain structural integrity.

Impact Absorption Capabilities

The impact absorption capabilities of concrete driveways are significantly improved with fibre reinforcement.

Fibres embedded in the concrete help distribute impact forces evenly across the surface, which reduces the risk of damage. For instance, using materials like steel and macro-synthetic fibres increases the toughness of the concrete and helps prevent cracks, allowing it to bear heavy loads and impacts without breaking.

The added flexibility from these fibres also helps the concrete cope with bending and minor settling, further reducing the likelihood of impact damage.

Consequently, fibre-reinforced concrete driveways offer excellent impact resistance, making them ideal for areas that experience frequent impacts and heavy vehicles, ultimately extending their lifespan.

Resistance to Fatigue

Incorporating fibres into concrete significantly boosts its resistance to fatigue, ensuring driveways can handle the demands of repeated loads without failing.

Fibre reinforcement tackles fatigue issues by:

- Increasing resistance to repeated loads, lowering the risk of failure.

- Enhancing post-cracking strength and toughness, vital for long-term durability.

- Offering effective crack control, preserving structural integrity under stress.

- Improving overall ductility, which allows for energy absorption during flexural stresses.

Polypropylene fibres perform well in low-stress situations, while steel fibres provide exceptional toughness at higher deflections.

Carbon fibres, when used correctly, strike a good balance between durability and load capacity.

This thoughtful use of fibres ensures your driveway remains robust against daily wear and tear.

Comparison With Traditional Rebar

Traditional rebar reinforcement significantly boosts a concrete driveway’s tensile strength and load-bearing capacity.

However, fibre reinforcement brings unique benefits in terms of crack resistance and durability. While rebar is excellent for handling heavy loads by providing a solid framework within the slab, fibre reinforcement focuses on controlling shrinkage and preventing early plastic cracking, promoting toughness rather than just strength.

Macro fibres help manage smaller cracks, while microfibres work to prevent early shrinkage cracks.

Although fibre-reinforced concrete may not be as strong as rebar for heavy loads, it distributes stresses more evenly, which reduces the risk of severe cracking.

Construction Efficiency

Integrating fibre reinforcement into concrete driveways improves construction efficiency by streamlining processes and cutting down on labour requirements.

This method significantly affects construction timelines and workforce efficiency in several ways:

- Quicker Placement: Fibre is pre-mixed, enabling rapid delivery and minimal handling on site.

- Lower Labour Demands: By removing rebar, the complexity and time needed for labour on site are greatly reduced.

- Easier Logistics: Avoiding the need for bulky steel transport helps to minimise congestion and storage issues.

- Enhanced Quality Control: Factory-controlled mixing ensures consistency and reduces variability, leading to fewer delays.

Cost Benefits of Fiber-Reinforced Concrete

Incorporating fibre reinforcement into concrete driveways can lead to significant cost benefits beyond just initial material expenses.

Although fibre-reinforced concrete (FRC) may incur higher upfront costs, it often eliminates the need for traditional steel rebar, which reduces both labour and material costs. The installation process is also simplified, especially with ready-mix delivery, which can save on labour time and help keep within budget.

Moreover, FRC is known for its durability, which decreases the frequency and costs of repairs over time, improving overall lifecycle cost performance.

This combination of lower maintenance requirements and a longer service life makes the initial investment worthwhile, offering financial advantages that make fibre-reinforced concrete a great choice for your driveway project.

Long-Term Serviceability

Choosing fibre-reinforced concrete for your driveway means investing in long-lasting durability.

This material offers excellent resistance to damage, which means less frequent maintenance and repairs.

As a result, you can enjoy a reliable surface that remains both structurally sound and visually appealing for years to come.

Enhanced Durability Over Time

Enhanced Durability Over Time

Incorporating fibre reinforcement significantly boosts the long-term durability of concrete driveways. This approach tackles essential issues like crack control, corrosion resistance, and mechanical toughness.

By adding fibres, you can enhance your driveway’s resilience, ensuring it stands up to the elements and the effects of ageing.

- Crack Control: Helps prevent cracks from forming and spreading, reducing the risk of water damage.

- Corrosion Resistance: Protects steel reinforcement from harmful substances, such as salt.

- Mechanical Toughness: Improves the ability to withstand stress, spreading loads more effectively.

- Environmental Protection: Lowers permeability, making it more resistant to freeze-thaw cycles and chemical damage.

Additionally, using fibre reinforcement can improve crack filling options, ultimately leading to a stronger driveway that can endure over time, reducing the need for maintenance.

Reduced Maintenance Intervals

Traditional concrete driveways can be a hassle due to frequent maintenance and repairs. However, using fibre reinforcement can significantly extend the time between these necessary interventions. By improving tensile strength, fibre reinforcement reduces crack formation and the need for repairs, ultimately enhancing the lifespan of your driveway.

With fewer microcracks, you won’t need to apply sealants as regularly, which cuts down on maintenance costs and disruption. The fibres also help control crack widths, reducing the likelihood of patch repairs and keeping your driveway looking good.

Longer intervals between maintenance not only save you money but also boost the driveway’s overall durability.

In short, fibre-reinforced driveways require less frequent upkeep, making them a more efficient and cost-effective choice for lasting performance.

Superior Resistance to Damage

Incorporating fibre reinforcement into concrete driveways significantly boosts their resistance to damage, ensuring they last longer. Here are the main benefits:

- Crack Control: Fibres enhance tensile strength, reducing the likelihood of cracks forming and spreading.

- Corrosion Resistance: Fewer cracks mean fewer entry points for harmful chemicals, which helps delay the corrosion of steel reinforcement.

- Mechanical Toughness: Macrofibres provide three-dimensional support, improving resistance to wear and increasing fracture toughness.

- Durability in Harsh Conditions: Lower permeability and reduced crack connectivity make the driveway more durable against moisture, salts, and temperature changes.

These advantages lead to excellent damage resistance, extending the lifespan of your concrete driveway and minimising maintenance over time.

Maintenance Considerations

Proper maintenance is crucial for the longevity and performance of your concrete driveway. Start with regular sweeping and pressure washing to clear away debris and stains that can damage the surface. Tackle oil and grease stains immediately to avoid lasting harm.

Every 2-3 years, apply a quality sealant to protect against moisture and chemicals, ensuring the surface is clean and dry beforehand.

Conduct regular crack inspections to catch and repair small issues early, which can prevent more extensive damage later on. Consider fibre reinforcement to improve durability and reduce the need for maintenance. Regular maintenance can extend the lifespan of your driveway from 15-20 years to 30-40 years, as seen with tarmac driveways.

Additionally, ensure proper drainage and address environmental factors to significantly extend your driveway’s lifespan while keeping upkeep to a minimum.

When to Choose Fiber Reinforcement

When considering the advantages of fibre reinforcement for your concrete driveway, it’s essential to determine when to use this technology.

Here are some key scenarios where fibre reinforcement shines:

- Heavy Loads: If your driveway will regularly bear the weight of vehicles or equipment, fibre reinforcement improves resistance to impact and fatigue.

- Fluctuating Weather: In areas with significant temperature changes, fibre reinforcement is crucial to minimise crack formation from freeze-thaw cycles.

- Lower Maintenance: If reducing long-term maintenance is a goal, the durability of fibre reinforcement can be a significant benefit.

- Complex Designs: For driveways that require unique shapes or extensions, fibre reinforcement simplifies the process without the need for complicated grids.

Frequently Asked Questions

How Does Fiber Reinforcement Affect Concrete Curing Time?

Fiber reinforcement does not change the curing time of concrete, but it does improve moisture retention and help control cracking. It’s still crucial to use effective curing methods to ensure proper hydration, allowing the concrete to reach its full strength within the expected timeframe.

Can Fiber-Reinforced Concrete Be Colored or Textured?

Yes, fibre-reinforced concrete can be coloured and textured much like a canvas. Various colouring techniques and texturing methods can be employed to achieve the desired look. For example, you might use dye or stain for colour, and stamped or brushed finishes for texture. It’s essential to ensure proper finishing to maintain a consistent appearance and integrity.

What Is the Lifespan of Fiber-Reinforced Driveways?

Fiber-reinforced driveways generally last between 30 and 50 years, thanks to their improved durability. To ensure they perform well and last as long as possible, it’s important to carry out regular maintenance, such as sealing and promptly repairing any cracks.

Are There Any Environmental Benefits of Using Fiber Reinforcement?

Yes, using fibre reinforcement provides environmental benefits by incorporating sustainable materials and eco-friendly practices. It helps reduce carbon emissions, minimises waste, enhances durability, and promotes resource conservation. For example, by using recycled fibres, we can decrease the need for new materials, leading to less environmental impact. Overall, this approach supports a more sustainable construction industry.

How Does Weather Impact the Installation of Fiber-Reinforced Concrete?

Weather conditions significantly impact the installation of fibre-reinforced concrete. For example, rapid changes in temperature can increase the likelihood of cracking by up to 30%. It’s essential to plan carefully and adjust mixing procedures to ensure optimal curing and to reduce the risk of performance issues.

Conclusion

Incorporating fibre reinforcement into your concrete driveway can significantly enhance its durability and reduce the risk of cracking. This approach not only strengthens the surface but also lowers maintenance costs over time. By choosing fibre reinforcement, you’re investing in a long-lasting and reliable driveway that can better withstand the challenges of weather and everyday use. It’s a practical choice for ensuring your home’s entrance remains in great condition for years to come.

Just how do stamped and plain concrete driveways compare in durability, cost, and aesthetics? Discover which option truly suits your Read more

Learn about the lifespan and durability of concrete driveways, and discover essential tips to ensure yours lasts for decades to Read more

On a budget? Discover how block paving and concrete driveways compare in costs and long-term value—your wallet might thank you!