When deciding between tarmac and concrete for commercial driveways, it’s essential to consider costs, durability, and maintenance. Tarmac is generally cheaper at the outset, lasting around 15 to 20 years, but it needs resealing every 3 to 5 years. On the other hand, concrete tends to be pricier initially, yet it can last 25 to 30 years and better withstands heavy loads.

Both materials raise environmental concerns, but the longer lifespan of concrete may justify its higher upfront costs. To make an informed decision, consider other crucial factors that influence performance and suitability for your specific needs.

Table of Contents

ToggleKey Takeaways

- Tarmac is more affordable upfront and quicker to install, making it suitable for short-term projects.

- In contrast, concrete lasts significantly longer, typically 25 to 30 years, while tarmac lasts around 15 to 20 years.

- Concrete can better support heavy vehicles, whereas tarmac may soften and crack under heavy loads.

- Although tarmac maintenance is usually cheaper and quicker, it does need resealing every 3-5 years.

- Concrete offers great aesthetic flexibility and strength, making it a preferred choice for commercial driveways, enhancing both appearance and functionality.

Cost Comparison: Tarmac vs. Concrete

When choosing between tarmac and concrete for commercial driveways, understanding the costs is essential for those on a budget.

Tarmac typically has lower upfront costs, ranging from £20 to £60 per square metre. This is mainly due to cheaper materials and quicker installation, which can help keep projects on schedule. Labour costs for tarmac are also lower since it takes less time to lay compared to concrete. However, remember that tarmac requires regular sealing and resurfacing, which can add to long-term expenses. Moreover, tarmac has a shorter average lifespan compared to concrete, making it crucial to evaluate long-term costs. Properly installed tarmac driveways can last 20 to 30 years with minimal upkeep, contributing to their appeal.

On the other hand, concrete usually has higher initial costs due to the variety of materials and the more intensive labour required. While it may need less maintenance and repairs over time, it’s crucial to consider all costs when deciding on your driveway to ensure a sound investment.

Durability and Longevity: Which Material Lasts Longer?

When choosing between tarmac and concrete for commercial driveways, durability and lifespan are key factors.

Concrete generally outlasts tarmac, with a lifespan of 25 to 30 years when properly maintained, compared to tarmac’s 15 to 20 years. Its resistance to extreme weather, such as freeze-thaw cycles, makes concrete a reliable option. Additionally, concrete can support heavier vehicles without losing strength, whereas tarmac tends to soften and crack in heat. While tarmac offers some flexibility, it usually deteriorates faster under heavy loads. This is particularly evident in cold climates, where tarmac remains more flexible but concrete’s durability prevails. Regular maintenance, such as routine inspections, is essential for maximizing the lifespan of both materials.

Therefore, if you’re prioritising longevity and durability, concrete is the more sensible choice for your commercial driveway.

Maintenance Requirements: Keeping Your Driveway in Top Shape

To keep your commercial driveway in prime condition, it’s important to know the maintenance needs for both tarmac and concrete.

Tarmac generally requires resealing every 3-5 years, while concrete sealing is done less often, typically every 2-3 years. Tarmac is recyclable and often made from recycled materials, which adds an eco-friendly benefit to its maintenance. Regularly applying eco-friendly sealants can enhance the durability of tarmac and protect it from environmental impacts.

Regular inspections are essential for both types; check for cracks and imperfections at least once a year to address any issues early.

Tarmac cracks and potholes should be patched every 5-10 years, whereas concrete cracks should be repaired promptly to prevent water damage. Repair techniques vary: tarmac repairs are usually quicker and cheaper, while concrete repairs may need professional help.

Following these guidelines will extend the life of your driveway and reduce long-term maintenance costs, keeping it both functional and attractive.

Environmental and Safety Considerations

Maintaining a commercial driveway requires attention to both environmental and safety factors. For example, tarmac production can lead to habitat loss, while cement manufacturing for concrete significantly contributes to global CO₂ emissions.

To lessen these impacts, consider using reclaimed tarmac or low-carbon concrete mixes.

Both traditional materials are impermeable, which can increase stormwater runoff and pollution, posing risks to local ecosystems. Opting for permeable alternatives can improve water management and reduce environmental harm.

Additionally, concrete typically has a longer lifespan than tarmac, which can help conserve resources over time. By considering these aspects, you can make a more informed choice for your commercial driveway.

Aesthetic and Customization Options for Commercial Driveways

When considering aesthetic and customisation options for your commercial driveway, the choice of finishes and textures can significantly enhance its visual appeal.

You have a variety of colour options to choose from, allowing you to create a look that aligns with your brand identity.

The appearance of your driveway is crucial, as it contributes to the first impression clients and visitors will have.

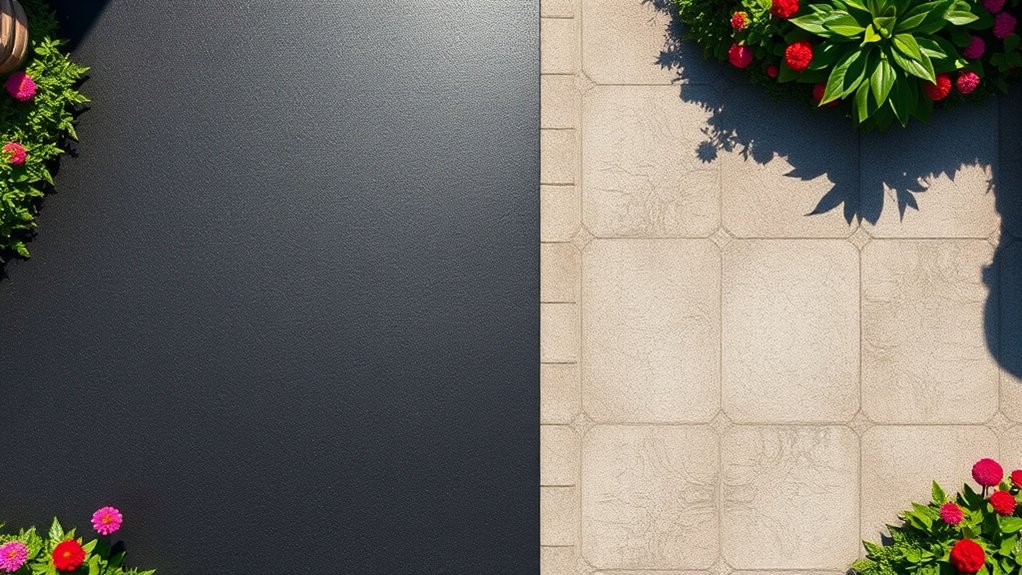

For instance, a sleek, dark asphalt surface might convey professionalism, while a patterned block paving could suggest a more welcoming atmosphere.

Custom Finishes and Textures

Custom finishes and textures for commercial driveways not only enhance visual appeal but also address specific functional needs.

Here are several finish options that offer a balance of customisation and practicality:

- Exposed Aggregate Finish: This option reveals decorative stones, providing a rustic appearance with excellent slip resistance.

- Broom Finish: An affordable choice that offers good traction and is easy to maintain, with modest customisation available.

- Stamped Concrete Texture: Designed to mimic high-end materials, this finish offers a wide range of design possibilities while ensuring durability.

- Stencilled Patterns: Ideal for creating intricate designs, including logos, this cost-effective option allows for flexible branding opportunities.

Selecting the right custom textures can significantly enhance both the aesthetics and functionality of your commercial driveway, ensuring it meets your specific needs.

Color Options and Variety

Colour options and variety are crucial in designing commercial driveways, impacting both their appearance and functionality.

Concrete driveways offer over 30 standard colours, including earth tones like grey, red, and tan, achieved through various pigment forms such as granular, liquid, and powder. These pigments ensure consistent colour throughout the slab, reducing patchiness. Custom blending allows for bright shades or subtle tones to align with branding.

In contrast, asphalt generally offers fewer base colours, primarily black or dark grey, with limited specialised coatings providing around 16 colours. While options exist for asphalt, they simply can’t match the extensive palette that concrete provides, making concrete the better choice for customisation in commercial driveway design.

Visual Impact Considerations

Visual impact is crucial when choosing materials for commercial driveways, as both aesthetics and customisation options significantly influence your decision.

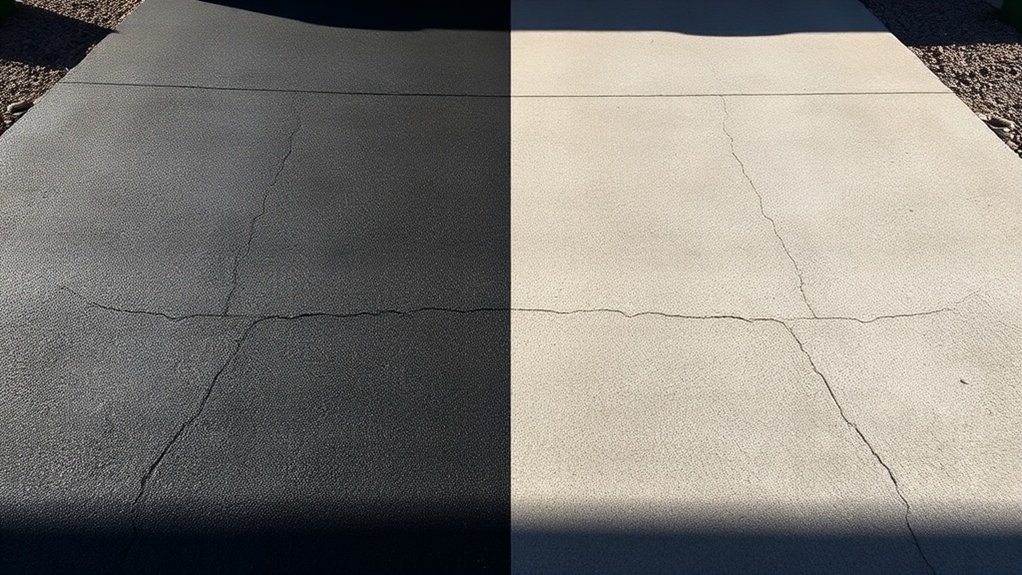

Tarmac offers a sleek, uniform look, while concrete allows for greater design flexibility with various textures and finishes.

Here are some essential points to consider regarding visual impact:

- Tarmac provides a smooth surface, whereas concrete can feature intricate patterns.

- Concrete can imitate natural materials like brick or stone, enhancing its customisation potential.

- The design flexibility of concrete enables it to blend well with different architectural styles.

- Both materials can boost curb appeal, but concrete’s versatility often results in a more striking visual effect.

Ultimately, your choice will hinge on the aesthetic you want to achieve and your functional needs.

Suitability for Commercial Use and Heavy Loads

When it comes to suitability for commercial use and heavy loads, concrete clearly outshines tarmac.

Concrete can support heavy trucks without bending or cracking, whereas tarmac tends to develop ruts under similar pressure. With compressive strengths of 3,000 to 5,000 psi, concrete offers excellent structural integrity, making it ideal for industrial settings.

It lasts 30 to 50 years compared to tarmac’s 15 to 20 years, resulting in lower long-term maintenance costs. Moreover, concrete is more resistant to wear from heavy traffic and chemical spills, unlike tarmac, which often needs regular repairs.

For heavy commercial use, concrete is undoubtedly the better choice, delivering the durability and stability needed for demanding environments.

Frequently Asked Questions

How Do Weather Conditions Affect Tarmac and Concrete Performance?

Weather conditions significantly affect the durability of tarmac and the flexibility of concrete. Tarmac generally performs better in freeze-thaw cycles, while concrete’s rigidity can make it prone to cracking in such conditions. On the other hand, concrete is more resilient in high temperatures, as it resists deformation better than tarmac, which can soften in the heat.

What Is the Best Method for Installing Tarmac or Concrete Driveways?

Installing a tarmac or concrete driveway doesn’t have to be complicated. The key to a long-lasting driveway lies in proper preparation and effective installation techniques. Start by clearing the site thoroughly, ensuring the area is free from debris and vegetation. Next, focus on creating a stable sub-base; this could involve compacting the soil or adding crushed stone to support the surface material. Lastly, ensure you employ skilled labour for the installation to achieve the best finish. By following these steps, you can enjoy a durable driveway that enhances your property.

Can Tarmac or Concrete Be Recycled After Removal?

Yes, tarmac can be recycled indefinitely without losing quality, while concrete can be reused as aggregate but has limitations. Both methods help conserve resources, cut down on landfill waste, and reduce environmental impact, making them sustainable options.

How Do Tarmac and Concrete Impact Property Value?

“You get what you pay for.” Tarmac may have lower upfront costs, but it doesn’t hold its value like concrete does. Concrete enhances property value through its durability and visual appeal, making it a better long-term investment for homeowners looking to boost their property’s worth.

What Are the Typical Installation Times for Tarmac and Concrete Driveways?

For tarmac driveways, the installation usually takes between 6 to 10 weeks. In contrast, concrete driveways can be poured in just 1 to 3 days. However, timelines for both types can vary due to factors like permits and the curing process.

Conclusion

When choosing between tarmac and concrete for your commercial driveway, it’s important to consider their distinct advantages. Tarmac is generally more affordable and offers greater flexibility, making it a good option for businesses on a budget. On the other hand, concrete is known for its exceptional durability and attractive finish, which can enhance the overall appearance of your property.

Think about what matters most for your situation—whether it’s cost, long-term durability, or ease of maintenance. For example, if you’re a small business looking to save money upfront, tarmac might be the better choice. However, if you seek a long-lasting surface that requires less frequent repairs, concrete could be worth the investment. By carefully evaluating these factors, you can select a driveway solution that meets your needs and adds value to your business.

Just how long can you expect your tarmac driveway to last? Discover key factors and maintenance tips that can extend Read more

From planning to final touches, discover the essential steps of tarmac driveway installation—what could go wrong if you skip any Read more

Wondering if a tarmac driveway is the perfect fit for your home? Uncover the essential pros and cons before making Read more