The average cost of installing a tarmac driveway in Manchester typically ranges from £1,500 to £5,000. This price can vary depending on the driveway size, site conditions, and any necessary groundwork. Generally, you can expect prices per square metre to be between £40 and £120. Total costs will also depend on the excavation and preparation required. Being aware of these factors can help you budget effectively. For a better understanding of pricing influences, consider researching further details.

Table of Contents

ToggleKey Takeaways

The cost of tarmac driveway installation in Manchester generally ranges from £1,500 to £5,000, depending on the size and condition of the site. On average, you can expect to pay between £40 and £120 per square metre for tarmac. For a typical 20m² driveway, installation might average around £1,100. Keep in mind that factors like excavation depth and soil stability can affect the final price. Premium installations often come with a 5-year guarantee, which adds value over time.

Understanding the Cost Range for Tarmac Driveways

When planning a tarmac driveway, it’s important to know the cost range, which can vary significantly. Typically, prices for tarmac driveways fall between £550 and £3,850, with an average cost per square metre ranging from £40 to £120. Your total bill usually lands between £1,500 and £5,000, depending on your driveway’s size. Properly installed tarmac driveways can last 20 to 30 years with minimal upkeep, making them a long-term investment. If you’re considering aesthetics, it’s worth comparing tarmac options, as these can impact your budget. Larger driveways incur higher prices when it comes to tarmac installation costs. Hot lay tarmac usually costs around £45 to £60 per tonne, while standard tarmac options range from £50 to £80 per tonne. Understanding these factors will help you make an informed choice for your driveway installation.

Factors Influencing Driveway Installation Costs

When planning your driveway installation, the groundwork and excavation can significantly affect your budget. The size and condition of your site determine the preparation needed, which can lead to higher costs. Additionally, both material and labour expenses can vary widely. It’s important to consider these elements to get a reliable estimate for your tarmac driveway in Manchester. For instance, a sloped site may require more excavation than a flat one, impacting the overall price. A tarmac driveway is known for durability, lasting up to 20 years with proper care. Proper site preparation is essential for ensuring a successful installation and can influence overall costs.

Groundwork and Excavation Needs

Groundwork and excavation are crucial in determining the cost of installing a tarmac driveway in Manchester, as they directly affect the complexity of the project and the materials needed.

Here are the key points to consider:

- Excavation Depth: Generally, you should aim for a depth of 200-250mm to ensure a solid sub-base and tarmac layer. Proper excavation guarantees that the sub-base materials can adequately support the tarmac.

- Soil Stability: Check that the soil is stable; if not, you may need to stabilise it to reach the required depth.

- Drainage Requirements: Ensure a 1-2% slope for effective drainage to avoid water pooling.

- Site Assessment: Look out for any saturated ground or organic material that needs to be removed for a proper foundation. Proper installation improves durability and prevents future issues, ultimately impacting long-term costs.

These factors significantly influence your installation costs and help ensure a durable and functional driveway.

Material and Labour Costs

Once you’ve laid a solid foundation and completed excavation, it’s time to consider material and labour costs, both of which significantly affect your driveway installation budget.

The quality of materials you select will influence pricing; for instance, hot lay tarmac costs between £45 and £60 per tonne and is known for its durability, while cold lay tarmac is a more affordable option for smaller repairs. On average, expect material costs to be around £50 per m².

Labour costs are also crucial, with specialists typically charging between £150 and £200 per day. The complexity of the installation and chosen techniques can impact these rates, averaging £50 to £80 per m².

Generally, the larger the area, the lower the cost per m², which can help balance your overall expenditure. By understanding these costs, you can make informed decisions for your tarmac driveway installation in Manchester.

Typical Components of Tarmac Driveway Quotes

When comparing tarmac driveway quotes, you’ll find important elements such as excavation, waste disposal, material costs, and labour charges.

Excavation usually costs around £28 per m², while tarmac materials can vary from £50 to £120 per m², depending on the type you choose.

Labour costs can also differ significantly based on local rates and the complexity of the job, affecting your overall installation cost.

Excavation and Waste Disposal

Excavation and waste disposal are crucial factors in the cost of installing a tarmac driveway. Here’s what you need to know:

- Excavation Costs: Expect to pay around £16 per m² for straightforward excavation. However, costs can rise if the conditions are more complicated.

- Waste Disposal: This usually costs about £28 per m², which covers the removal of any existing materials.

- Equipment Hire: Renting a mini digger typically costs £250 per day or £150 per week. This equipment is essential for efficient excavation.

- Labour: A two-person skilled team can charge roughly £400 per day, influenced by the complexity of the ground and the project.

Effective waste management and sound excavation practices are key to reducing expenses while ensuring a quality driveway installation.

Tarmac Material Costs

Understanding tarmac material costs is crucial for planning your driveway installation. Tarmac typically ranges from £70 to £120 per m², with an average cost of around £90, including materials.

There are two main types of tarmac: hot-mix and cold-lay. Hot-mix tarmac costs about £45 per tonne and covers approximately 8m². Cold-lay options are available for £8 to £15 per 25kg bag, making them suitable for smaller DIY projects.

For a 30m² driveway, you’ll need about 3 to 4 tonnes of hot-mix, which will cost between £285 and £440, including delivery.

Keep in mind that larger areas often reduce the cost per m² due to economies of scale. Additionally, the installation techniques you choose can significantly affect your overall material costs.

Labour and Equipment Charges

When planning your tarmac driveway installation, it’s essential to factor in labour and equipment charges, which are key elements of your overall quote.

Here’s a breakdown to help you budget effectively:

- Labour Costs: Expect to pay specialists between £150 and £200 per day. This can vary based on the size and complexity of your driveway.

- Excavation Charges: These are typically £28 per m², covering the removal of any existing materials needed for new foundations.

- Sub-Base Costs: Preparation usually averages £23 per m². If you require new foundations, there may be an additional charge of around £1,000.

- Equipment Rentals: Costs will depend on the scale of your project, including any delivery fees. This equipment is crucial for effective excavation and laying of the tarmac.

Price Examples Based on Driveway Size

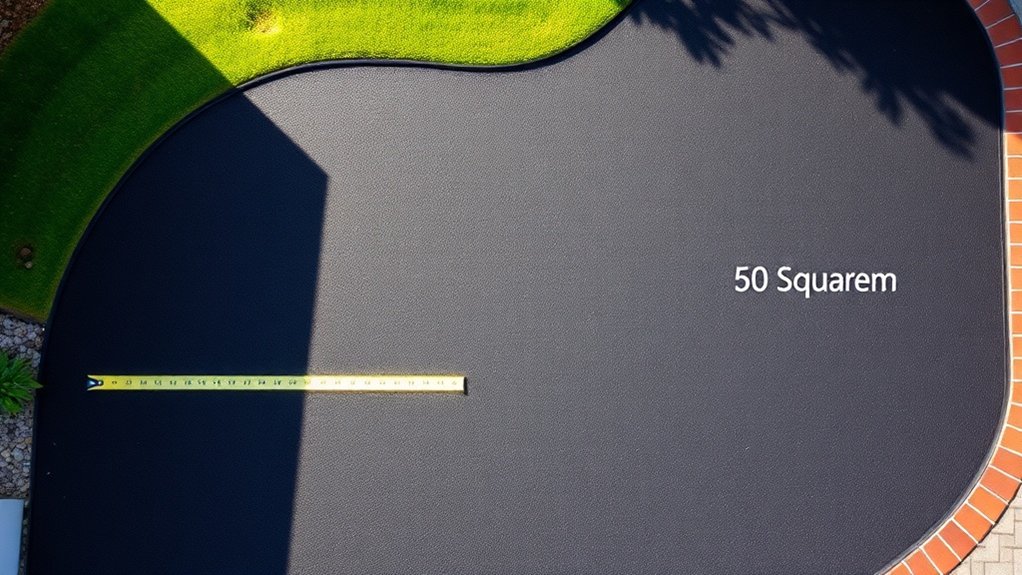

When planning a tarmac driveway, size significantly affects the overall cost.

A 10m² driveway typically costs around £550, ideal for a single small vehicle.

For a 20m² driveway, expect an average cost of £1,100, providing space for one car with some extra room.

A 30m² driveway averages £1,650, which can accommodate one to two cars.

If you’re looking at a larger 50m² driveway, anticipate costs around £2,750, while a 70m² or larger driveway can cost £3,850 or more.

Keep in mind that prices can vary based on driveway types and installation methods, so it’s wise to evaluate your specific requirements for an accurate quote.

Maintenance and Lifespan Considerations

To keep your tarmac driveway in top shape, it’s important to consider maintenance and lifespan. Here are some straightforward tips to extend its life:

- Regularly check for damage to spot issues early.

- Clean the surface well to ensure sealant adheres properly.

- Fill potholes or seal cracks quickly to prevent further damage.

- Reapply sealant every few years to protect against the weather.

With proper care, your driveway can last up to 20 years, especially if installed by professionals.

A 5-year guarantee on premium installations further enhances your investment in your property.

Tips for Sourcing Quotes and Choosing Contractors

Proper maintenance of your tarmac driveway can significantly extend its lifespan, but choosing the right contractor for installation or repairs is just as crucial. To ensure transparency in quotes, always ask for itemised estimates that detail per square metre rates and specific costs for groundwork, drainage, and edging. It’s wise to gather at least three competitive quotes to make informed comparisons between contractors.

| Key Factors | Importance |

|---|---|

| Itemised Quotes | Provides a clear cost breakdown |

| Contractor Credentials | Confirms reliability and expertise |

| Local Experience | Ensures knowledge of local conditions |

| Written Guarantees | Offers protection against workmanship issues |

Frequently Asked Questions

How Long Does the Installation Process Typically Take?

The installation process usually takes between 1 to 4 days, depending on factors such as the size of the driveway and the complexity of the site. For larger projects, it may take up to 2 weeks, particularly if there are groundwork requirements or adverse weather conditions to consider.

Are There Eco-Friendly Tarmac Options Available?

Yes, there are eco-friendly tarmac options available! Using sustainable materials like recycled asphalt can cut runoff by up to 90%. Consider permeable tarmac or Stone Mastic Asphalt (SMA) for their durability and environmental advantages in your driveway project.

Can I Install a Tarmac Driveway Myself?

You can attempt a DIY tarmac driveway for small patches, but be aware of the challenges involved. Achieving proper compaction and dealing with temperature-sensitive materials can make things tricky. If you make mistakes, it could end up costing you more in repairs than if you had hired a professional.

What Permits Are Required for Driveway Installation in Manchester?

Before installing a driveway in Manchester, it’s important to check local regulations. You may need planning permission if you’re installing a dropped kerb or if your driveway covers more than 5 square metres with impermeable materials. Ensuring you comply with these rules is crucial to avoid enforcement actions and unexpected costs.

How Do I Maintain My Tarmac Driveway After Installation?

Consider your tarmac driveway as a protective barrier. To maintain it, prioritise regular surface cleaning and sealing. This simple upkeep will prolong its lifespan and ensure it remains looking smart for years to come. For instance, sweeping away leaves and debris can prevent staining, while applying a sealant every few years helps to protect against the elements.

Conclusion

When it comes to home improvement, particularly tarmac driveways, the saying “you get what you pay for” is very much applicable. Understanding the cost range, what affects pricing, and the usual components of quotes can help you make informed choices. A properly installed tarmac driveway not only boosts your property’s value but also its longevity. Be sure to obtain multiple quotes and select a reputable contractor. A wise investment now can prevent future hassles and additional costs, ensuring you have a durable and visually appealing driveway.

Just how long can you expect your tarmac driveway to last? Discover key factors and maintenance tips that can extend Read more

From planning to final touches, discover the essential steps of tarmac driveway installation—what could go wrong if you skip any Read more

Wondering if a tarmac driveway is the perfect fit for your home? Uncover the essential pros and cons before making Read more