DALTEX Resin Bound Aggregates offer a top-notch surfacing option for your home’s outdoor areas.

You’ll get UV-stable tech that keeps colours vibrant and ensures durability, backed by a 15-year guarantee.

These aggregates meet SUDS standards, so you won’t need planning permission, and they drain brilliantly.

With 50 colour choices and custom patterns on offer, you can boost your property’s kerb appeal whilst enjoying minimal upkeep.

The permeable surface fights off weeds and frost, perfect for British weather.

Costs typically run from £60 to £100 per square metre, depending on various factors.

Getting to grips with DALTEX aggregates will help you make a smart choice for your home improvement project.

Table of Contents

ToggleKey Takeaways

DALTEX offers top-notch, UV-stable resin bound aggregates for driveways and garden paths, backed by a 15-year guarantee.

The product meets SUDS requirements, eliminating the need for planning permission and providing eco-friendly drainage solutions.

With 50 colour options, homeowners can create bespoke patterns and designs for their outdoor spaces.

The permeable surface prevents puddles, resists weeds and frost, and needs little upkeep throughout the year.

Installing DALTEX resin bound aggregates can boost property value and kerb appeal significantly. Imagine impressing your neighbours with a sleek, modern driveway that looks fantastic year-round.

What is a DALTEX Resin Bound Aggregate?

DALTEX Resin Bound Aggregates are top-notch surface solutions for UK homeowners.

These carefully chosen and graded aggregates ensure excellent performance and looks. They’re versatile, allowing you to match your home’s style perfectly.

DALTEX uses high-quality materials and strict quality checks, making their product stand out.

Whether you’re redoing your driveway or sprucing up your garden path, these aggregates offer a durable and attractive option that’s hard to beat.

The Premium Choice

DALTEX Resin Bound Aggregates offer a top-notch option for UK homeowners after tough and good-looking surfacing.

These aggregates are dead flexible in design and can be tailored to suit your home’s look. You’ll get UV-stable resin tech that fights fading and discolouration, paired with first-rate aggregates chosen for their strength and appearance.

DALTEX products come with a 15-year guarantee, giving you long-term peace of mind for your investment.

Think of it like choosing a bespoke suit that’s both stylish and hard-wearing – that’s what DALTEX brings to your driveway or patio.

UV-stable resin technology

UV-stable resin technology is crucial for maintaining the look of your outdoor surfaces. DALTEX Resin Bound Aggregates use this innovative feature to ensure UV resistance, long-lasting performance and colour retention.

Unlike standard epoxy resins that can discolour over time, DALTEX’s UV-stable technology uses additives like Hindered Amine Light Stabilisers (HALS) to slow down this process significantly. These UV-stable coatings shield against sun damage, reducing fading and wear.

High-quality aggregates

Quality is the cornerstone of top-notch surfacing. DALTEX’s premium aggregates undergo thorough durability tests and careful sourcing to ensure consistent colour and longevity. Our eco-friendly materials come in various sizes to suit your project needs.

| Aggregate Type | Size Range (mm) | Eco-Friendly |

|---|---|---|

| Fine | 1-3 | Yes |

| Medium | 3-5 | Yes |

| Coarse | 5-8 | Yes |

| Mixed | 1-8 | Yes |

| Custom | Variable | Yes |

Whether you’re resurfacing a driveway or creating a garden path, DALTEX aggregates provide the durability and aesthetics you’re after. Our range covers everything from fine grains for smooth finishes to coarse options for more textured surfaces.

15-year product guarantee

DALTEX offers a robust 15-year product guarantee, giving homeowners peace of mind for their surfacing investments. This warranty covers material defects and premature wear, ensuring long-lasting results.

Like other resin driveways, DALTEX resin bound aggregates provide environmental benefits, including better natural water filtration and reduced runoff. These features support sustainable water management.

For claims, DALTEX’s customer service team offers straightforward guidance. It’s worth reviewing the warranty details to fully understand your coverage and make the most of this guarantee.

Benefits for Your Home

DALTEX Resin Bound Aggregates offer numerous benefits for your home. They boost kerb appeal and property value, two key advantages for any homeowner.

The eco-friendly, permeable surface helps prevent flooding, a common concern in the UK’s rainy climate. You’ll find these driveways are long-lasting and easy to maintain, saving you time and money in the long run.

The wide range of colours and smooth finish let you create attractive surfaces that suit your home’s style and garden.

Whether you’re in a terraced house in Manchester or a detached property in Surrey, DALTEX driveways provide practical and stylish solutions for British homes.

Practical Advantages

DALTEX Resin Bound Aggregates offer practical benefits for your home’s exterior.

They’re SUDS compliant, so you won’t need planning permission, and their permeable surface prevents puddles.

These aggregates are environmentally friendly, lasting as long as concrete without the ecological impact.

They’re low-maintenance, resist weeds and frost, and keep your outdoor spaces looking smart for years.

Perfect for British gardens and driveways, they’re a sensible choice for homeowners keen on both practicality and sustainability.

SUDS compliant (no planning permission needed)

DALTEX resin bound aggregates offer a key advantage: they’re SUDS compliant. This means you won’t need planning permission for your driveway or patio.

The permeable nature of DALTEX provides eco-friendly drainage solutions for homes.

Benefits of SUDS compliance:

- Lowers flood risk

- Naturally filters water

- Replenishes groundwater

Skipping planning permission:

- Saves time

- Cuts costs

- Simplifies installation

These features make DALTEX a practical choice for UK homeowners looking to upgrade their outdoor spaces without bureaucratic hassle.

Permeable surface prevents puddles

Resin bound surfaces offer a practical solution to puddle formation on your property.

This eco-friendly material allows water to seep through, providing excellent drainage. It’s SuDS compliant, which means it helps manage flood risks and reduces strain on water treatment facilities.

The surface remains durable throughout the seasons, keeping its water-permeable qualities intact. When properly installed, it effectively disperses water, preventing standing pools and reducing slip hazards.

You’ll end up with a puddle-free surface that’s both functional and looks good.

Low maintenance requirements

DALTEX resin bound surfaces boast low maintenance needs due to three key factors.

Firstly, their tough surface withstands wear and tear brilliantly.

Secondly, eco-friendly aggregates resist stains and fading.

Lastly, the seamless finish stops weeds and cuts seasonal upkeep.

The sleek look of these surfaces adds kerb appeal without extra effort.

With proper DIY installation, you’ll get a durable, low-maintenance surface that needs minimal care year-round.

Weed and frost resistant

DALTEX resin-bound surfaces offer exceptional resistance to weeds and frost, alongside low maintenance. Acting as natural weed barriers, these surfaces prevent unwanted growth.

The frost-resistant materials withstand Britain’s seasonal temperature changes, reducing cracking and heaving. These driveways also help manage rainwater and reduce flooding risks, a common concern in many UK neighbourhoods.

As an eco-friendly option, DALTEX minimises outdoor maintenance, allowing you to spend less time on seasonal garden tasks and more time enjoying your durable, attractive outdoor space.

Perfect for those seeking a practical, long-lasting solution for their driveways or patios.

Design Benefits

DALTEX resin bound aggregates offer impressive design benefits for your home.

With 50 stunning colour options and the ability to create custom patterns, you can personalise your outdoor surfaces.

The design flexibility allows for curves and unique layouts, boosting your property’s kerb appeal.

The smooth, seamless finish elevates your home’s exterior, creating a visually striking look that’s sure to impress neighbours and visitors alike.

50 stunning color options

DALTEX resin bound aggregates offer 50 stunning colour options for homeowners.

You’ll find colours that match current trends and seasonal palettes, perfect for creating eye-catching combinations.

These customisable designs not only boost your property’s kerb appeal but also let you express your personal style.

When choosing hues for your outdoor spaces, consider the impact of colour psychology.

DALTEX ensures long-lasting colour durability, keeping your chosen shades vibrant for years.

With these options, you can easily tailor your property’s look to suit your taste.

Smooth, seamless finish

Resin bound aggregates offer a smooth, seamless finish that boosts your home’s kerb appeal.

This modern surface fits current design trends, providing a uniform texture that’s both attractive and practical.

The installation method ensures perfect colour blending, creating a cohesive look across your outdoor space.

The flexible resin delivers a visually pleasing finish that enhances your property’s overall aesthetic value.

This seamless finish adds a contemporary and sophisticated touch to driveways, patios and walkways, improving your home’s overall look.

Custom patterns available

Custom patterns can make your property stand out, adding a personal touch to your outdoor areas.

DALTEX resin bound aggregates offer creative options for your landscaping. You can add artistic flair with unique designs, from simple shapes to complex patterns.

Colour choices let you match your driveway to your home’s exterior. Mixing colours and styles can create an eye-catching feature that boosts your property’s kerb appeal.

These personalised patterns express your style while keeping the durability of resin-bound surfaces. Such customisation can enhance your property’s look and value.

Enhanced curb appeal

Homeowners looking to boost their property’s kerb appeal can greatly benefit from DALTEX resin bound aggregates.

These surfaces blend seamlessly with your garden, creating a harmonious look that enhances outdoor aesthetics.

With a wide range of colours and design options, you can personalise your driveway or path to match your home’s style and surroundings.

The sleek, modern appearance of resin bound surfaces significantly increases property value and neighbourhood appeal.

You’ll notice improved kerb appeal as the aggregates complement your home’s architecture and local environment, creating a cohesive and attractive exterior.

Cost Considerations

When weighing up DALTEX resin bound aggregates for your property, you’ll need to grasp the cost breakdown and price factors.

The total bill typically covers materials, labour, and any necessary groundwork. The complexity of installation and ground conditions can greatly affect the overall cost, as they influence the time and effort needed for proper fitting.

Key factors impacting the price include the size of the area, your chosen aggregate type and colour, installation complexity, and where you live in the UK.

For instance, a simple driveway in the Midlands might cost less than an intricate patio design in central London.

It’s worth getting a few quotes to compare prices and ensure you’re getting good value for money.

Price Breakdown

When looking at DALTEX resin bound aggregates for your property, consider several cost factors.

The average price per square metre typically includes materials and professional installation, varying based on project complexity and chosen aggregate types. Prices generally start from about £100 per square metre, often making resin driveways more affordable than traditional block paving.

Design options, aggregate quality, and location can significantly affect overall costs.

While the initial outlay may seem high, it’s worth considering the long-term benefits: durability, low maintenance, and potential increase in property value.

Think of it as an investment in your home’s future, much like upgrading your kitchen or bathroom.

Average costs per square meter

The average cost for DALTEX resin bound aggregates in the UK typically ranges from £60 to £100 per square metre.

Several factors impact this price, including:

- Installation challenges

- Environmental considerations

- Colour durability

- Surface texture

- Project complexity

Larger projects, customisation options, and specific installation requirements can affect the overall cost of resin driveways.

While pricier options might offer better looks and longevity, more affordable choices can still yield good results.

Many homeowners find that resin driveways strike a nice balance between cost and quality, often praising their durability and appearance.

Material expenses

Material expenses for DALTEX resin bound aggregates typically make up 40-60% of the total project cost. To save money when planning your budget, consider these tips:

| Material | Cost Range (£/m²) | Sourcing Tips |

|---|---|---|

| Resin | 15-25 | Buy in bulk |

| Aggregate | 10-20 | Use local quarries |

| Primer | 5-10 | Compare different brands |

| Additives | 2-5 | Use only if necessary |

| Tools | 3-8 | Consider renting vs buying |

Keep detailed records of expenses for accurate financial planning and efficient material sourcing. This approach will help you manage costs effectively and avoid overspending on your DALTEX project.

Installation costs

Installation costs typically account for 40-50% of the total expense in a DALTEX resin bound aggregate project.

When planning your budget, consider:

- Materials sourcing: Bulk purchases can cut costs

- Contractor selection: Experienced pros may charge more but ensure quality

- Installation timelines: Shorter timeframes might increase labour costs

Project size and complexity greatly impact overall costs.

Larger or more intricate driveways need more materials and labour, affecting the final price.

Weighing these factors can lead to long-term savings.

Proper installation boosts durability, cutting future maintenance costs and making the most of your investment.

Long-term value

When considering the long-term value of DALTEX resin bound aggregates, it’s essential to break down costs over time. The residential durability makes it a lasting investment.

Resin driveways’ exceptional longevity and resistance to cracking ensure a stable surface with minimal upkeep. You’ll save money through reduced maintenance and replacement costs. The eco-friendly materials boost property value, adding to your home’s worth.

These benefits contribute to the overall cost-effectiveness of DALTEX resin bound aggregates throughout their lifespan. For example, a well-maintained resin driveway could last 20 years or more, compared to traditional surfaces that may need replacing after just a few years.

In the long run, this durability translates to significant savings and peace of mind for homeowners.

Factors Affecting Price

When pricing DALTEX resin bound aggregates for your property, several key factors come into play. The state of your existing surface, total coverage area, and design complexity all significantly impact the final cost.

Access for installation equipment and materials is crucial; tricky or limited access might mean extra labour or specialist gear, bumping up the price.

Don’t forget about the British weather and how often you’ll use the surface – these can affect long-term upkeep, potentially adding to your resin driveway’s overall cost.

For example, a large, intricately patterned driveway with poor access in a high-traffic area might cost more than a simple, small patio in an easily accessible garden.

It’s best to consider all these factors when budgeting for your project.

Current surface condition

The current surface condition is crucial in determining the overall cost of DALTEX resin bound aggregate installation. A thorough pre-installation inspection is vital.

Concrete or tarmac provide the best foundation for resin driveways, ensuring longevity and stability. Key factors to consider:

- Substrate integrity check

- Surface repair options

- Current surface assessment

Any issues must be addressed before installation, which may increase costs. Poor surface conditions often require extra preparation, potentially including repairs or a new base layer.

For example, a cracked concrete driveway might need patching or complete replacement before the resin can be applied. It’s worth sorting these problems out early to avoid headaches down the line.

Size of area

The size of the area to be covered is crucial when determining the cost of DALTEX resin bound aggregate installation. Key factors to consider:

| Area Dimensions | Design Considerations |

|---|---|

| Surface Layout | Space Planning |

| Accessibility | Material Requirements |

Precise measurements and space planning are vital for estimating materials and labour costs. Complex layouts or tricky access might increase expenses. Larger areas often work out cheaper per square metre, whilst smaller spaces may need more detailed design work.

It’s like planning a new kitchen – the size and shape of the room, along with how easy it is to get materials in and out, all affect the final cost. In my experience, it’s always better to be thorough with measurements to avoid nasty surprises later on.

Design complexity

When it comes to design complexity, intricate patterns and custom layouts significantly affect the cost of DALTEX resin bound aggregate installations.

Consider these factors:

- Colour schemes and visual impact

- Outdoor aesthetics and practicality

- Material textures and how they blend

The design flexibility of DALTEX allows for borders, curves, and unique layouts, boosting kerb appeal and complementing your home’s style.

Complex designs require more time, skill, and materials, which increases the price.

However, they can vastly improve your property’s look and value.

Many UK homeowners find this investment worthwhile for creating distinctive, high-quality outdoor surfaces.

Access requirements

Access requirements are crucial in determining DALTEX resin bound aggregate installation costs. You’ll need to assess entry points for machinery and materials, along with driveway size and vehicle clearance.

The process often uses specialised equipment like forced action mixers, which may need specific access checks. Foot traffic during installation could affect timelines. You might also need permits, impacting overall costs.

Reviewing these factors beforehand helps with accurate budgeting and avoids surprise expenses. For example, a narrow driveway might require smaller machinery, potentially increasing labour time and costs.

It’s wise to consult with installers early on to identify any potential access issues.

Installation Process

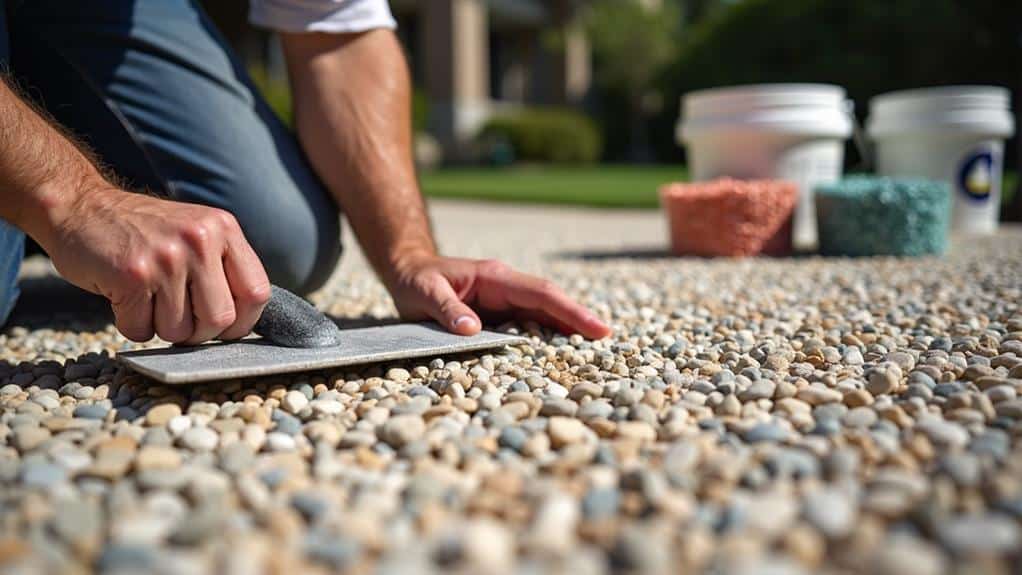

The DALTEX resin bound aggregate installation involves two key stages: preparation and application.

Ensure proper surface prep by cleaning, fixing any damage, and priming. Professional advice is crucial for a stable, level base that can support the resin surface.

For installation, mix the resin with your chosen aggregates and spread evenly across the prepared area. Think of it like icing a cake – you need a smooth, flat surface before you can apply the topping.

This process might seem daunting, but with the right guidance, you’ll end up with a durable, attractive surface that’ll last for years.

Preparation

For a top-notch DALTEX resin bound aggregate installation, start with a thorough site assessment.

Check the existing surface and surroundings, looking out for drainage problems and soil stability. Sort out any minor base issues to avoid future headaches.

Proper surface prep is crucial – clean, repair or prime the base for the best adhesion.

Keep an eye on the weather, as temperature and humidity can make or break the curing process and final quality.

A bit of careful planning goes a long way in ensuring a cracking result.

Site assessment

A thorough site assessment is crucial before installing DALTEX resin bound aggregate. This comprehensive evaluation involves:

- Checking drainage to ensure proper water flow

- Examining surface integrity to spot existing issues

- Evaluating environmental impact to meet regulations

Carefully inspect the area’s topography, soil conditions, and existing structures.

It’s vital to assess the base for cracks, crumbling, or other damage that could affect the resin installation.

Fixing minor base issues now can prevent future problems with the resin surface.

This detailed inspection will guide your installation plan and help avoid potential snags.

Surface preparation

After the site assessment, proper surface preparation is crucial for installing DALTEX resin bound aggregate.

Evaluate the substrate, check moisture levels, and use appropriate levelling methods. Suitable bases for resin driveways include porous concrete and tarmac, which should be crack-free for effective installation.

Preparation techniques vary depending on the existing surface. Ensure you have the right tools for cleaning, repairing, and priming the area.

Good preparation is key to achieving a long-lasting, attractive finish.

Weather considerations

When installing DALTEX resin bound aggregates, weather plays a key role in ensuring success. Consider:

- Temperature: Affects resin curing time

- Seasons: Rainfall may delay work

- Humidity: High moisture can weaken bonds

Rain during curing can seriously damage resin driveways, so it’s vital to check the forecast before starting.

Water exposure can cause surface flaws, impacting the driveway’s long-term performance.

Keep an eye on the weather and plan accordingly. Ideal conditions include dry surfaces, temperatures between 5°C and 30°C, and low humidity.

Avoid working in extreme weather for best results.

The Installation

Installing DALTEX Resin Bound Aggregates involves key steps for top-notch results.

Start with proper base prep, then mix resin and aggregates precisely. Suitable bases include porous concrete and tarmac, but they must be crack-free and spotless.

The application technique and curing time are crucial for a durable, high-quality finish.

Base preparation

Proper base preparation is crucial for a successful DALTEX resin bound aggregate installation.

Check ground stability and surface integrity before starting. Consider eco-friendly options for base materials and drainage. Concrete or tarmac make suitable bases for resin driveways, with porous concrete being ideal for both new and existing installations.

Follow these steps:

- Assess existing surface condition

- Excavate and level the area

- Install appropriate sub-base and edging

A well-prepared base prevents settling, cracking, and drainage issues, ensuring your DALTEX resin bound surface lasts longer and performs better.

Think of it like building a house – a solid foundation is key to avoiding problems down the line.

Mixing process

DALTEX’s mixing process is crucial for top-notch resin bound surfaces.

Follow the specified mixing ratio for your chosen aggregates. Ensure proper resin consistency using a forced action mixer.

The mixing typically occurs during the 24-hour curing period for resin driveways, allowing ideal setting and hardening.

Always don protective gear and follow safety guidelines when handling resins.

Thorough mixing is vital to prevent weak spots and ensure a uniform, durable finish.

Application technique

Mastering the application technique is crucial for a top-notch DALTEX resin bound surface. Proper surface prep is a must before applying the mixture. Suitable base layers like porous concrete or tarmac should be thoroughly cleaned and checked for cracks beforehand.

Follow these key steps:

- Spread the mixed resin and aggregate evenly with a trowel.

- Smooth the surface using a power float for consistency.

- Hand-trowel finish for intricate details.

Always wear protective gear during installation. Allow enough curing time for best results.

In my opinion, taking your time with each step is well worth it for a professional finish.

Think of it like icing a cake – rushing the process can lead to a messy outcome.

Curing time

Curing time for DALTEX resin bound surfaces varies based on temperature, humidity and aggregate mix. Environmental factors play a crucial role in the process. A general guide to curing duration:

| Temperature | Humidity | Curing Duration |

|---|---|---|

| Low (<10°C) | High | 48-72 hours |

| Moderate | Moderate | 24-48 hours |

| High (>25°C) | Low | 12-24 hours |

For best results, aim for moderate temperatures and low humidity. This ensures a quicker, more effective cure. Think of it like drying paint – warm, dry days are ideal, while damp, chilly conditions slow things down.

Choosing Your Design

When selecting your DALTEX resin bound aggregate design, consider colour choices and pattern options.

Choose from a variety of natural and vibrant hues to complement your home’s exterior or garden. Customisable colour palettes allow for unique driveway aesthetics, and it’s crucial to match these colours with your house exterior for a cohesive look.

Pattern options include different aggregate sizes and mixes, creating distinctive textures and visual effects for your outdoor spaces. For example, a warm, sandy blend might suit a coastal property, while a sleek grey could work well with modern architecture.

In our opinion, the right combination can significantly boost your property’s kerb appeal.

Color Selection

When choosing colours for your DALTEX resin bound surface, you’ll find plenty of options to match your taste.

Modern greys and natural stone shades offer a classic look, while bold colours can make a real statement.

The flexible design allows for curved paths and unique patterns, boosting your property’s kerb appeal.

You can also add contrasting borders to define areas and create visual interest in your outdoor space.

Whether you fancy a subtle, elegant finish or something more eye-catching, there’s a DALTEX colour scheme to suit your style.

Contemporary greys

Contemporary grey tones are all the rage in modern landscape design, giving homeowners a smart and flexible colour palette for their resin bound surfaces.

DALTEX’s contemporary greys fit right in with current landscaping trends and colour psychology, making outdoor spaces look top-notch. These eco-friendly resin surfaces offer a sustainable and long-lasting alternative to traditional paving, meeting SUDs regulations while still looking great.

Consider these options:

- Silver Birch: Light and reflective

- Pewter: Mid-tone with a hint of warmth

- Charcoal: Deep and grounding

These shades can inspire your design and work well with various modern looks.

Whether you’re after a sleek patio or a stylish driveway, these greys are sure to impress.

Natural stones

Beyond modern greys, DALTEX offers a range of natural stone colours that mimic traditional paving materials.

These include various stone types, chosen for their durability and finish.

When picking natural stones, consider their environmental impact.

Sustainable options like DALTEX’s natural stone aggregates provide both aesthetic variety and support eco-friendly landscaping.

These aggregates offer the beauty of authentic materials while ensuring long-lasting, environmentally responsible resin-bound surfaces.

Statement colors

Many homeowners want to make a statement with their driveways and patios, and DALTEX’s bold colours are ideal for this.

When choosing your colour scheme, consider:

- Colour psychology: How different shades affect mood

- Current trends: Popular combinations in landscape design

- Design inspiration: Your home’s architecture and surroundings

Customisable colour palettes create unique looks for driveways.

It’s crucial to match driveway colours with your home’s exterior for a cohesive appearance. Varying shades can make your driveway stand out.

DALTEX’s range of statement colours lets you create eye-catching surfaces that complement your property’s style.

For example, a charcoal grey driveway can add a modern touch to a traditional brick house, while warm terracotta tones work well with Mediterranean-inspired homes.

Border options

Border options play a crucial role in enhancing your driveway’s look when using DALTEX resin bound aggregates.

Various designs and styles can complement your main surface, from contrasting aggregates to brick pavers. Colour variations create striking accents or subtle changes, while customisable palettes ensure your driveway integrates seamlessly with your home’s exterior.

Consider different installation techniques to achieve your desired aesthetic and practical needs. A well-chosen border can dramatically boost your property’s kerb appeal, making it stand out in the neighbourhood.

Pattern Options

When choosing pattern options for your DALTEX resin bound surface, you’ll find plenty of design choices.

Customisable colour palettes let you create a unique look that complements your home’s exterior. You might go for a single colour for a sleek finish, or mix colours to add interest.

For a more detailed look, consider adding decorative borders or bespoke patterns that suit your property’s style.

Whether you fancy a modern driveway or a classic garden path, DALTEX offers versatile options to suit your taste.

Single color finish

A single colour finish offers a clean, elegant look for your resin bound driveway or patio. This option has several benefits:

- Improved visual appeal through design consistency

- Quicker installation, cutting time and labour costs

- Use of colour psychology to create desired atmosphere

Single colour finishes create a uniform appearance that complements your home’s exterior.

They’re perfect for those after a minimalist, modern look whilst maintaining the durability and permeability of resin bound systems.

You can choose from various colours and textures to match your personal taste and home’s architecture, much like selecting the right paint for your living room walls.

Multi-color designs

Multi-colour designs offer homeowners more creative options than single-colour finishes for resin bound surfaces.

Colour blending techniques allow for unique artistic expressions, incorporating texture variations and intricate patterns. You can add borders and patterns to enhance kerb appeal and complement your home’s architecture.

Draw inspiration from nature, buildings, or current trends to create eye-catching surfaces. These designs can transform your outdoor space, adding depth and character to driveways, patios, and paths.

Consider a swirling pattern for your driveway or a mosaic-style design for your patio to make a bold statement.

Decorative borders

Decorative borders can greatly enhance the look of your resin bound surface and define specific areas. Consider these options:

- Contrasting colour combinations using different aggregate blends

- Intricate patterns created with specialised border materials

- Geometric shapes achieved through precise installation techniques

The flexibility in design allows for customisation that boosts kerb appeal and complements your home’s architecture.

With various options available, it’s easy to create unique and eye-catching borders.

Look at different design inspirations to find a border that suits your main surface.

Custom patterns

Beyond decorative borders, custom patterns offer homeowners a chance to create truly unique resin bound surfaces.

Explore various design trends to personalise your space. The flexibility allows for curves and unique layouts, enhancing your driveway’s look.

Consider geometric shapes, organic curves, or intricate motifs. Installation techniques ensure precise execution of your chosen design.

Try different colour combinations for greater visual impact. DALTEX’s customisation options let you tailor patterns to your specific tastes and property layout.

Whether you fancy a modern, angular design or a more traditional, flowing pattern, the choice is yours to make your driveway stand out.

Maintenance and Care

Maintaining your DALTEX resin bound surface is crucial for its longevity and looks.

Sweep it weekly to clear debris and prevent stains. For tough marks, use a mild detergent and water mix, or specialist cleaners suited to the stain type.

Give it a thorough clean with a pressure washer or garden hose twice yearly to shift stubborn grime and keep the surface permeable.

This routine will keep your driveway or patio looking top-notch and performing well for years to come.

Regular Maintenance

To keep your DALTEX resin bound surface in top condition, regular upkeep is essential.

Sweep often and occasionally clean with a pressure washer to remove debris and maintain its appearance.

Steer clear of harsh chemicals that might harm the resin.

Focus on preventing stains to keep your aggregate looking smart.

For best results, consider booking professional maintenance every so often.

Simple cleaning methods

Keeping your DALTEX resin bound surface clean is a doddle. Simple cleaning methods and everyday products do the trick. To keep it looking top-notch:

- Sweep away leaves and rubbish regularly

- Break out the pressure washer for a thorough clean

- Tackle stubborn marks with a mild soap solution

Give it a once-over every 4-6 weeks to keep it shipshape and prevent build-up.

For oil spills, chuck some cat litter on to soak it up, then wash with soap.

Come spring, you’ll want to sort out any moss or algae. A mix of vinegar and water works a treat, and specialised brushes make light work of it all.

Seasonal care

Seasonal changes bring unique challenges for DALTEX resin bound surfaces, requiring tailored care throughout the year.

Key seasonal maintenance tasks include:

Spring: Thorough cleaning, moisture management

Summer: Mitigating temperature effects

Autumn: Leaf removal, preparing for winter

Winter: De-icing, seasonal inspections

Adapt your maintenance routine to address these seasonal factors, ensuring your DALTEX surface stays in top condition year-round.

Regular checks and prompt attention to issues will extend the life and look of your resin bound aggregate surface.

For example, in autumn, clear fallen leaves promptly to prevent staining and slipping hazards.

In winter, use suitable de-icing products to avoid surface damage.

These simple steps can make a world of difference in maintaining your surface’s quality and safety.

Stain prevention

DALTEX resin bound surfaces generally resist staining, but you can take steps to further reduce the risk:

- Watch out for common culprits: oil, grease, and fallen leaves.

- Apply a protective sealant yearly.

- Use the right cleaning products for different stains.

Regular brushing and quick clean-up of spills are crucial to prevent stains from setting. Tackle potential marks straight away to keep your resin driveway looking its best.

Clean your surface regularly, following a guide for suitable cleaning solutions.

Adjust how often you clean based on use and weather to ensure top-notch stain prevention and a long-lasting DALTEX surface.

Professional servicing

DALTEX resin bound surfaces are tough, but professional servicing is key to keeping them in top shape.

It’s essential to find reputable contractors who know their stuff and can meet proper installation and maintenance standards. Regular check-ups by certified pros can spot and sort out potential problems early on.

When choosing a contractor, look at their past work, customer reviews, and how well they know DALTEX products.

Think about your surface’s specific needs when weighing up service options. Expert care ensures your surface stays in good nick, nipping issues in the bud before they get out of hand.

Finding an Installer

When choosing a contractor for your DALTEX resin bound aggregate installation, consider these key points:

- Look for experienced pros certified in resin bound surfacing.

- Check their portfolio of completed projects.

- Do your homework on local firms with solid reputations.

- Get written quotes from several contractors to compare prices.

- Verify credentials and insurance.

- Ask for references from past clients.

By following these steps, you’ll be more likely to find a trustworthy and skilled installer for your project.

Choosing a Contractor

When choosing a contractor for your DALTEX resin bound aggregate installation, consider these key points:

- Check the contractor’s certification and experience with resin bound systems.

- Research local firms with solid reputations and proper licensing.

- Get written quotes from several contractors to compare prices.

- Verify their insurance coverage and warranty terms.

It’s crucial to do your homework on potential contractors.

A reputable firm should have no qualms about providing references or showing examples of their previous work.

Don’t be swayed by the lowest price alone; quality and reliability are just as important.

Certification requirements

Choosing the right contractor for DALTEX resin bound aggregates is crucial for a top-notch installation. Opt for professionals with proper accreditation from recognised certification bodies who follow strict standards.

Well-installed resin driveways offer excellent durability and resist cracking. When selecting a contractor, ensure they:

- Have completed DALTEX’s official training

- Follow industry-specific installation guidelines

- Know safety regulations and testing procedures

These certifications guarantee your installer has the know-how to handle DALTEX products properly, ensuring your driveway looks great and lasts for years.

Experience level

Experience is crucial when choosing a contractor for DALTEX resin bound aggregate installations.

Look for firms with a solid track record and plenty of completed projects. A reputable contractor should communicate clearly and offer transparent customer service. They’ll provide useful advice on installation, product comparisons and maintenance.

Experienced installers can also give more accurate cost estimates. When vetting contractors, ask about their years in the business and the number of DALTEX installations they’ve done.

This approach will help ensure you get top-notch results for your project.

Insurance coverage

When choosing a contractor for your DALTEX resin bound aggregate installation, insurance coverage is crucial. Proper installation is key for top-notch results and longevity.

Ensure your selected contractor has:

- Sufficient liability cover

- Comprehensive insurance for property damage and worker injuries

- Adequate coverage limits for your project’s size

Check their policy details and understand how to make claims. Ask for proof of their insurance before agreeing to anything. This safeguards you from potential financial risks during the installation process.

Warranty offered

When choosing a contractor for your DALTEX resin bound aggregate installation, warranty coverage is crucial.

Top-notch installers typically offer comprehensive warranties with clear terms and durations. Ask for detailed warranty information, including how to make claims and access customer support.

Professional installation is key for optimal results and to avoid issues like cracking. Consider the contractor’s experience with resin bound surfaces and their history of successful projects.

Compare warranties from different installers to ensure you’re getting the best protection for your investment. Don’t be shy about asking questions regarding warranty terms and conditions.

A solid warranty can provide peace of mind, much like having a safety net when walking a tightrope.

What to Expect

Understanding the project timeline is crucial when planning your DALTEX resin bound aggregate installation.

You’ll typically go through a three-phase process: site preparation, installation, and curing.

Before installation begins, skilled resin teams carry out thorough groundwork preparation, including excavation and drainage, to ensure a top-notch driveway.

The entire project usually takes 2-5 days, depending on the size and complexity of your space.

It’s like having your kitchen redone – proper planning and preparation lead to a smoother, more efficient process and a better end result.

Project Timeline

DALTEX resin bound aggregate projects start with a quick consultation to assess your needs and site.

Installation usually takes 1-3 days, depending on the area size and design complexity. Our skilled contractors ensure proper application for optimal durability and longevity of your resin driveway.

After installation, allow 24-48 hours for curing before use. We’ll conduct a final check to ensure the surface meets our high-quality standards.

The whole process is straightforward and efficient, giving you a top-notch driveway with minimal fuss.

Initial consultation

The initial consultation kicks off your DALTEX resin bound aggregate project. In this meeting, you’ll discuss:

- Your preferences and material options

- Budget and project scope

- Rough timeline and logistics

Your contractor will use a checklist to ensure all key points are covered. This step is crucial for aligning expectations, addressing concerns, and laying the groundwork for your project’s success.

They’ll explain the installation process and discuss different resin types, like epoxy, polyurethane, and acrylic, helping you make an informed choice.

This meeting sets the tone for your project, so come prepared with questions and ideas. It’s your chance to get a clear picture of what to expect and how to achieve the best results for your outdoor space.

Installation duration

After sorting project details in your initial consultation, you’ll want to know how long the installation will take.

DALTEX Resin Bound Aggregates typically take 2-5 days to install, depending on the size and complexity of your project.

Factors like site readiness, weather, and labour availability can affect this timeline.

It’s best to hire professionals for installation to ensure quality results and compliance with local rules.

Good project coordination keeps things running smoothly and reduces disruption.

Your contractor will give you a precise schedule based on your specific project needs.

Curing period

Understanding the curing period is crucial for your DALTEX Resin Bound Aggregates project. Curing times vary based on conditions:

- Temperature: Warmer weather speeds up curing, cooler slows it down. Resin driveways typically need 24 hours to fully cure before vehicles can drive on them, but this may change with the weather.

- Humidity: Too much moisture can delay curing and affect the finish.

- Typical timeframes:

- Light foot traffic: 24 hours

- Vehicle traffic: 48-72 hours

- Full cure: 5-7 days

Final inspection

Once your DALTEX Resin Bound Aggregates project has fully cured, it’s time for the final check.

Your contractor will carry out quality checks using a final inspection list. This process is crucial for ensuring the longevity of your driveway, which can last up to 25 years with proper care.

You’ll need to be there during this process, which usually takes 1-2 hours. They’ll look at surface evenness, colour consistency, and proper drainage.

Common snags include small imperfections or uneven spots. You’ll have the chance to raise any concerns before signing off on the project.

Aftercare Support

After installing DALTEX Resin Bound Aggregates, it’s crucial to understand your warranty coverage. Typically, the warranty protects against manufacturing faults and early wear under normal use.

Regular upkeep is key to maintaining your driveway’s looks and longevity. This means routine cleaning with mild detergents and quickly sorting out any surface cracks or stains.

Do read the warranty terms carefully, noting the duration, exclusions, and any maintenance needed to keep it valid.

Taking good care of your driveway will help you avoid costly repairs down the line and keep it looking smart for years to come.

Warranty Coverage

DALTEX provides a comprehensive 15-year warranty for their resin bound aggregates, covering both material faults and installation snags.

The warranty protects against cracking, splitting and UV damage, with a simple claims process via their customer service team.

The exceptional longevity and durability of resin driveways back up this lengthy warranty period, giving homeowners peace of mind.

To keep your warranty valid, you’ll need to follow specific care guidelines, including regular cleaning and steering clear of harsh chemicals on the surface.

It’s like having insurance for your driveway – just remember to treat it well, and it’ll serve you for years to come.

15-year guarantee

DALTEX Resin Bound Aggregates offers a 15-year guarantee, providing peace of mind for UK homeowners.

This comprehensive warranty includes:

- Workmanship guarantees for installation

- Coverage for material defects

- Assurance of eco-friendly materials

Annual maintenance advice helps you get the most from your investment.

Customers often praise DALTEX’s quality and service.

This robust guarantee ensures your resin-bound surface stays attractive and functional for years, making it a smart choice for driveways and patios across Britain.

What’s included

DALTEX offers comprehensive aftercare support and warranty coverage for homeowners’ peace of mind.

You’ll get installation tips, maintenance advice and design ideas to make the most of your DALTEX surface.

Colour matching help ensures your project looks its best.

The package includes clear care instructions to keep your resin-bound surface looking great for years.

DALTEX’s support team is on hand to answer any questions after installation.

How to claim

To make a warranty claim for your DALTEX resin-bound surface:

- Take clear photos of the problem and write a detailed description.

- Ring up your DALTEX installer or authorised rep.

- Have your proof of purchase and installation date ready.

It’s a bit like filing an insurance claim – the more evidence you’ve got, the smoother it’ll go.

While it might seem a faff, it’s worth doing to protect your investment.

After all, you wouldn’t want to be out of pocket for something that should be covered.

Maintenance requirements

Proper upkeep is crucial for maintaining your DALTEX resin-bound surface warranty. Stick to regular cleaning and seasonal care to ward off weathering.

Tackle common problems like stains or small cracks quickly, using methods approved by the manufacturer. Steer clear of harsh chemicals and power washing, as these can harm the surface.

Follow the maintenance guide to keep your DALTEX surface in top shape and within warranty terms.

Frequently Asked Questions

Can DALTEX Resin Bound Surfaces Be Installed Over Existing Concrete or Asphalt?

DALTEX resin bound surfaces can indeed be laid over existing concrete or asphalt, provided proper surface preparation is carried out. This feature offers a cost-effective way to revamp old driveways or patios. Before installation, it’s crucial to ensure adequate drainage and consider design options that suit your property. Regular maintenance, such as occasional sweeping and pressure washing, will keep your new surface looking top-notch for years to come.

How Long Does It Take for a DALTEX Resin Bound Surface to Cure?

A DALTEX resin bound surface typically cures in 24-48 hours. Best results occur in dry weather with mild temperatures. Proper application is crucial for optimal curing. Steer clear of heavy foot or vehicle traffic during this period. Once set, the surface requires minimal upkeep and has a low environmental impact. Think of it like waiting for paint to dry – patience pays off for a long-lasting finish.

Are DALTEX Resin Bound Surfaces Suitable for Areas With Freezing Temperatures?

DALTEX resin bound surfaces are indeed suitable for areas with freezing temperatures. Most DALTEX surfaces can withstand freeze-thaw cycles, making them a reliable choice for British winters. For best results in cold weather, ensure proper installation, maintain good drainage, and account for thermal expansion. With a range of colour options available, you can choose a surface that looks great all year round, from frosty mornings to sunny summer days.

Can Vehicle Oil Stains Be Removed From DALTEX Resin Bound Surfaces?

Oil stains on DALTEX resin bound surfaces can be sorted with the right cleaning method. Use a proper degreaser, give it a gentle scrub, and rinse well. For a DIY fix, stick to the maintenance advice and think about adding surface protection to keep future stains at bay. It’s like cleaning a greasy kitchen worktop – a bit of elbow grease and the right product will do the trick.

Is It Possible to Repair Small Damaged Areas Without Replacing the Entire Surface?

Small damaged areas can indeed be repaired without replacing the entire surface. Proper repair techniques, including colour matching and careful aggregate selection, are crucial. While DIY repairs are possible, professional surface maintenance often yields better results for seamless integration. For example, a chipped worktop might be fixed with a matching resin filler, but a specialist could ensure a flawless finish. In our experience, it’s worth weighing up the cost of professional repairs against the risk of a botched DIY job, especially for visible or high-use areas.

Conclusion

You’ve now got a solid grasp of DALTEX resin bound aggregates for your home. These surfaces can last up to 25 years with proper care – that’s a quarter-century of durability and kerb appeal for your property. As you decide, think about your design preferences, budget and how much upkeep you’re willing to do. It’s worth chatting with professional installers to ensure you’re making the right choice for your specific needs. For example, if you’ve got a busy driveway, you might want a tougher mix than someone who’s just doing a garden path. In my opinion, the long-lasting nature of these surfaces makes them a smart investment for many homeowners.

How can you banish stubborn moss from your tarmac driveway? Discover effective methods, from manual scraping to chemical treatments, and Read more

Stained tarmac driveway ruining your curb appeal? Discover effective techniques to tackle even the toughest blemishes and restore your driveway's Read more

Improve your tarmac driveway's appearance and longevity with our comprehensive guide, covering essential cleaning techniques and maintenance tips that will