Yes, a concrete driveway requires rebar or reinforcement to improve its durability and performance. Rebar enhances tensile strength, enabling the driveway to bear heavier loads and minimising the chance of cracks due to temperature fluctuations and ground movement. This is particularly important for thicker slabs or areas with unstable soil. By investing in proper reinforcement, you ensure a longer-lasting surface. Consider exploring different types of reinforcement, placement methods, and alternatives to maximise your driveway’s strength.

Table of Contents

ToggleKey Takeaways

- Rebar improves the tensile strength of concrete driveways, enabling them to bear heavier loads and minimising the risk of sagging and cracking.

- Reinforcement is particularly important for thicker driveways (5 inches or more) and in areas prone to expansive soil or freeze-thaw cycles.

- Correct spacing and installation of rebar, along with adequate concrete cover, are vital for effective reinforcement and long-lasting durability.

- Alternative options like fibre mesh and wire mesh can provide some reinforcement but may not be as effective as rebar.

- Investing in reinforced driveways can lead to greater durability and lower maintenance costs, making the higher initial investment worthwhile.

Importance of Rebar in Concrete Driveways

While you may think that concrete alone is enough for a driveway, adding rebar significantly improves its strength and durability. Rebar provides enhanced tensile strength, enabling the driveway to bear heavier loads and distribute the pressure from vehicles more evenly. This prevents sagging and cracking, which can extend the life of your driveway. Reinforced concrete also reduces the size and spread of cracks caused by temperature fluctuations and soil movement, helping to maintain its appearance and lower maintenance costs. Moreover, rebar helps the concrete endure freeze-thaw cycles, which can otherwise lead to surface damage. Rebar is commonly seen in driveways, patios, and foundations, demonstrating its widespread importance in concrete installations.

When Is Reinforcement Necessary?

When deciding whether to reinforce a concrete driveway, consider the following key factors:

- Soil Conditions: If the soil is expansive or unstable, reinforcement is essential to reduce cracking and movement.

- Concrete Thickness: A driveway that’s 10 cm (4 inches) thick generally requires wire mesh, whereas one that’s 12.5 cm (5 inches) or thicker benefits from rebar.

- Traffic Load: Heavier vehicles necessitate more robust reinforcement to effectively distribute loads and withstand tensile forces.

- Climate Factors: In areas prone to freeze-thaw cycles or significant temperature variations, using higher-strength concrete alongside reinforcement is advisable. Additionally, proper drainage management is crucial to prevent water accumulation that can compromise the driveway’s structural integrity.

Common Types and Sizes of Rebar

When choosing rebar for your concrete driveway, it’s important to understand the common sizes and thickness recommendations. Consider the load requirements to ensure proper support and durability. Selecting the appropriate type and size of rebar can significantly influence how well your driveway performs and how long it lasts. For instance, using 12mm or 16mm rebar is often recommended for residential driveways, depending on the expected vehicle load. Additionally, incorporating steel rebar into your driveway enhances its tensile strength, making it more resistant to cracking and tension forces.

Typical Rebar Sizes

Rebar, an essential element for reinforcing concrete, comes in various sizes for different applications. Choosing the right size for your driveway is crucial.

Here are some common rebar sizes:

- #10 Rebar: 10mm diameter, suitable for standard residential slabs.

- #12 Rebar: 12mm diameter, ideal for heavier loads and thicker slabs.

- #16 Rebar: 16mm diameter, provides extra support for larger homes or challenging soil conditions.

- #20 Rebar: 20mm diameter, used in high-stress areas.

Selecting the correct rebar size improves structural integrity, offering benefits like increased tensile strength and reduced cracking.

Consider factors such as load expectations and soil stability to ensure optimal performance.

Thickness Recommendations

Choosing the right thickness for your driveway slab is crucial for its durability and performance. A thickness of 100mm (4 inches) is typically sufficient for lighter vehicles, while 150mm (6 inches) is better for heavier traffic or unstable ground conditions.

Using properly placed rebar, generally #10 for 100-150mm slabs, enhances load-bearing capacity. If you expect significant stress, consider #12 rebar for thicker slabs or #16 rebar for larger residential setups.

It’s essential to maintain a uniform thickness throughout the slab to avoid weak points that can lead to cracking. In high-stress situations, closer rebar spacing (30-45cm) can further strengthen the slab, ensuring your driveway can handle the demands placed upon it.

Load Considerations

Understanding load considerations is crucial for selecting the right rebar for your driveway. The type and size of rebar you choose will impact its performance under various loads.

Here are common rebar types and sizes based on expected loads:

- #10 Rebar (10 mm): Suitable for standard driveways with light traffic.

- #12 Rebar (12 mm): Recommended for heavier vehicles or thicker slabs.

- #16 Rebar (16 mm): Necessary for larger projects or challenging ground conditions.

- Special Conditions: Larger rebar sizes may be required for unstable soils or thicker slabs.

Choosing the appropriate rebar ensures proper structural support, enhancing the durability and performance of your driveway.

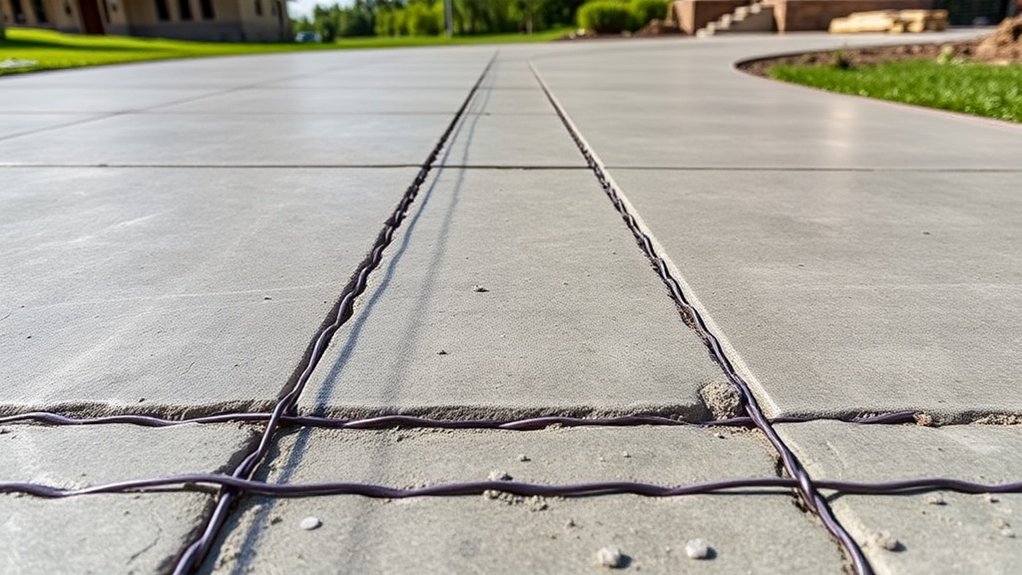

Best Practices for Rebar Placement and Installation

Proper placement and installation of rebar are crucial for the strength of a concrete driveway. Start by adhering to the recommended spacing, which is generally 300mm (12 inches) between bars.

Use rebar chairs or blocks to ensure a minimum cover of 75mm (3 inches) of concrete. Secure the intersections of the rebar with tie wire to keep them stable during the pour.

Place the rebar in the lower third of the slab to ensure it’s well-encapsulated and doesn’t shift. Before pouring the concrete, double-check your layout against engineering specifications.

Planning your rebar arrangement in advance will help streamline the installation process and reduce on-site adjustments, ensuring your driveway is properly reinforced.

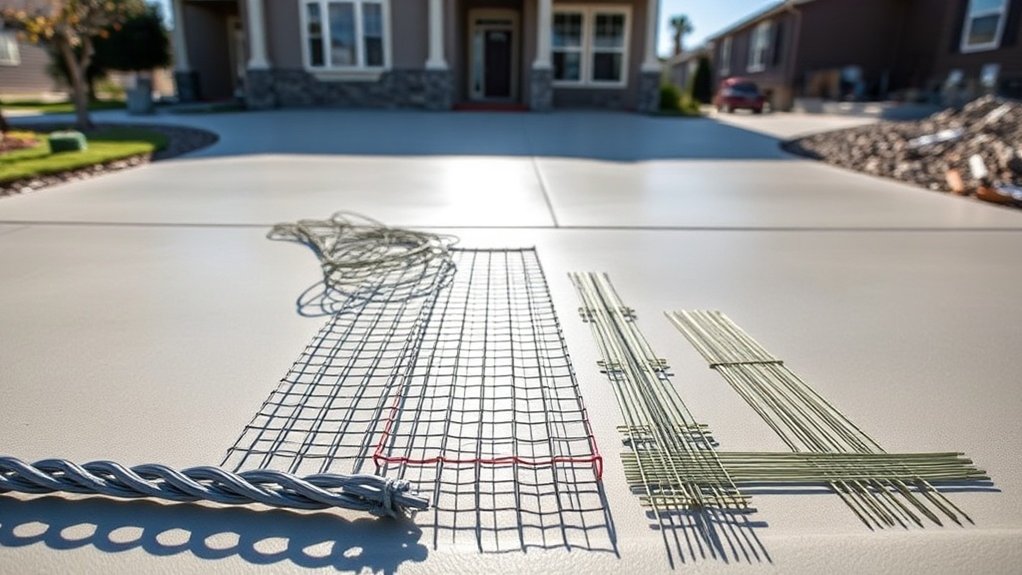

Alternative Reinforcement Methods

While rebar is a strong option for reinforcing concrete driveways, there are several alternative methods that can enhance durability and performance.

Here are some options to consider:

- Fibre Mesh: This involves adding synthetic or steel fibres to the concrete mix, which helps improve crack resistance and flexural strength, particularly in thinner slabs.

- Wire Mesh: A steel grid that provides medium-level reinforcement, offering a balance between strength and ease of installation. However, it can be prone to corrosion if not properly protected.

- Eco-Friendly Options: Systems like permeable turf-stone pavers allow for water drainage while providing structural support, making them a sustainable choice.

- Hybrid Strategies: Combining rebar with fibre mesh can significantly boost tensile strength and crack control, which can extend the lifespan of your driveway. This approach is particularly effective when used alongside high-quality fillers that enhance durability.

These alternatives can provide effective reinforcement tailored to your specific needs, ensuring a long-lasting concrete driveway.

Building Codes and Engineering Recommendations

When building a concrete driveway, it’s crucial to follow local building regulations and engineering guidelines to ensure safety and durability. Generally, you’ll need a building permit that confirms adherence to specific standards, such as a minimum slab thickness of 150 mm (6 inches) and a compressive strength of 24 MPa (3,500 psi).

Depending on the site conditions, regulations may require the use of #3 or #4 rebar, spaced 300 to 450 mm apart. Engineers advise placing the rebar at mid-depth within the slab to improve strength and resistance to cracking.

Adjustments to the size and spacing of the rebar may be necessary based on anticipated loads or soil conditions. Following these practices helps avoid structural issues and ensures your driveway lasts for years.

Cost Considerations for Reinforcement Options

Understanding the cost implications of reinforcement options is crucial for anyone considering a concrete driveway. Here are key factors to consider when comparing costs:

- Material Type: Unreinforced driveways generally cost between £4 and £8 per square foot, while reinforced options can go up to £25 per square foot.

- Reinforcement Type: Wire mesh is more affordable than rebar but offers less strength.

- Site Preparation: Costs for excavation and grading can significantly impact your total expenditure.

- Decorative Finishes: Adding aesthetic elements can increase costs and may require additional reinforcement.

Although reinforced driveways may have higher upfront costs, they offer long-term benefits through increased durability and fewer repairs, making them a sensible investment. Additionally, proper moisture levels during the curing process can enhance the effectiveness of the reinforcement.

It’s essential to assess these factors carefully to make the most of your budget.

Frequently Asked Questions

Can I Use Rebar From Previous Projects for My Driveway?

You can reuse rebar for your driveway, but make sure to check it for damage, rust, and compliance with local building regulations. Cleaning and straightening the bars properly will improve bonding and overall strength in the new concrete. For instance, if the rebar has significant rust or bends, consider replacing it to ensure your driveway is durable.

How Long Does Rebar Last in Concrete Driveways?

Rebar in concrete driveways usually lasts between 25 to 50 years, greatly improving the durability of the concrete. Its lifespan can be affected by factors such as the quality of installation, local weather conditions, and regular maintenance. For instance, a well-installed rebar in a driveway exposed to mild weather and properly maintained can last longer than one in harsher conditions. Proper care ensures optimal performance throughout its life.

What Happens if I Don’T Use Rebar?

If you don’t use rebar, your driveway could crack like a spider’s web under pressure. Without proper load distribution, it becomes unstable, leading to expensive repairs and a significantly reduced lifespan. Avoid unnecessary risks—reinforce your concrete!

Can I Install Rebar Myself?

Yes, you can install rebar yourself. Learning the proper techniques for layout and securing rebar can greatly enhance your concrete reinforcement project. Ensure you are familiar with local regulations and have the right tools for a successful installation. For instance, using a rebar cutter and bender can make your job much easier.

Is Rebar Necessary for Decorative Concrete Driveways?

Yes, rebar is important for decorative concrete driveways. It helps prevent cracking and maintains the driveway’s strength, ensuring that your attractive design lasts, even with heavy vehicles. For instance, if you live in an area with fluctuating temperatures, rebar can provide the support needed to withstand these changes while keeping your driveway looking its best.

Conclusion

In conclusion, reinforcing your concrete driveway with rebar can significantly improve its strength and durability, similar to how steel supports a bridge. While it’s not always essential—particularly for smaller driveways—considering your specific requirements and local building regulations is wise. By adhering to best practices for placement and installation, you can ensure a long-lasting surface. Investing in proper reinforcement can help you avoid expensive repairs later on, making it a sensible choice for homeowners.

Just how do stamped and plain concrete driveways compare in durability, cost, and aesthetics? Discover which option truly suits your Read more

Learn about the lifespan and durability of concrete driveways, and discover essential tips to ensure yours lasts for decades to Read more

On a budget? Discover how block paving and concrete driveways compare in costs and long-term value—your wallet might thank you!