Resin bound gravel is a top choice for outdoor surfaces in the UK. It blends stone with clear resin, creating a tough, good-looking finish that’s kind to the environment. You can choose from loads of colours and textures, ideal for your drive, patio or garden path.

Installing it iss not a DIY job – you’ll need the pros. They’ll sort the base and pick the right weather for laying. The mix lets water drain through easily, ticking the box for SUDS rules.

You’ll end up with a long-lasting surface that looks great and adds value to your home. It’s low-maintenance too, so you won’t be spending your weekends cleaning it.

If you’re after a modern look for your outdoor space, resin bound gravel’s worth considering.

Table of Contents

ToggleKey Takeaways

Resin bound gravel is a tough, easy-care surface made of resin and stones, perfect for driveways, patios and paths. You’ll need a pro to install it properly, as it requires careful groundwork and the right weather to set correctly.

One of its best features is how well it drains water, meeting SUDS rules and helping prevent flooding – a real plus in our rainy climate. You can choose from loads of colours and textures, giving your property a unique look that’ll likely boost its value.

For areas where people walk, aim for a 15-18mm layer. If cars will be driving on it, go for 18-20mm. It’s a bit like choosing the right thickness of carpet for different rooms in your house – you need more cushioning where there’s more wear and tear.

Understanding Resin Bound Systems

Understanding resin bound systems requires knowledge of their key components.

These typically include a two-part resin binder and carefully chosen aggregates. A range of colours and textures are available, allowing for bespoke designs that boost property value.

The elements are mixed to create a hard-wearing, porous surface that’s both attractive and practical.

Many UK homeowners opt for resin bound driveways due to their low maintenance and durability, particularly in areas prone to heavy rainfall.

Core Components

To understand resin bound systems, you need to grasp what resin bound gravel is and its material makeup.

These systems offer permeable surfaces that allow natural water drainage, reducing puddles and erosion. They’re also low-maintenance compared to traditional options.

Resin bound driveways comply with Sustainable Urban Drainage Systems (SUDS) regulations, providing eco-friendly solutions for outdoor spaces.

Different system types are available, so you can choose the best option for your project.

For example, a resin bound driveway could be ideal for a family home, offering both durability and aesthetic appeal whilst meeting local planning requirements.

What is Resin Bound Gravel?

Resin bound gravel is a popular surfacing option in UK landscaping and construction. It’s a mixture of stone aggregates and clear resin that creates a tough, porous surface. This method is eco-friendly and offers a range of looks to suit different tastes.

Classic Stone Driveways, a Manchester-based company started in 2019, specialises in resin bound solutions for driveways, paths and patios. Their focus on long-lasting, customisable designs has helped boost the popularity of this surfacing choice.

Installation usually involves mixing and trowelling the material onto a prepared base. While initial costs might be higher, resin bound systems often work out cheaper in the long run due to their durability and low upkeep needs.

For homeowners looking to spruce up their outdoor spaces, resin bound gravel offers a practical and attractive option that can withstand the British weather and look good for years to come.

Material Composition

Understanding the key components of resin bound systems is crucial for appreciating their versatility and durability. These systems blend resin and aggregate materials, often sourced sustainably. Colour additives and texture variations allow for customisation, while eco-friendly materials ensure environmental responsibility. Rigorous performance testing guarantees longevity.

| Component | Function | Variations |

|---|---|---|

| Resin | Binding | Clear, Tinted |

| Aggregate | Structure | Stone, Glass |

| Additives | Enhance | UV Stabilisers |

This blend of materials creates surfaces that are not only practical but also aesthetically pleasing. For instance, a driveway made with a resin bound system could incorporate locally sourced stone aggregates, offering a unique look that complements the surrounding landscape. The use of UV stabilisers is particularly important in the UK’s variable climate, helping to maintain the surface’s appearance over time.

SUDS Compliance

Many resin bound systems comply with Sustainable Urban Drainage Systems (SUDS) regulations, offering effective drainage whilst minimising environmental impact.

SUDS compliance is crucial for maintaining resin driveway integrity and preventing flooding by allowing natural water drainage. When considering SUDS compliance for your resin bound gravel project, keep in mind:

- Permeable surface requirements

- Water filtration capabilities

- Runoff reduction measures

- Proper installation guidelines

- Maintenance for long-term performance

Understanding these aspects will help you meet SUDS regulations and create a sustainable, eco-friendly surface.

For example, a well-installed resin driveway can handle heavy rain without puddles forming, unlike traditional paving. This not only looks better but also helps reduce local flood risks.

System Types

The core of every resin bound surface is a carefully engineered system. Different resin types and installation methods affect performance and environmental impact. Key elements include:

| Component | Function | Options |

|---|---|---|

| Resin | Binding agent | Polyurethane, epoxy |

| Aggregate | Visual appeal | Stone, recycled glass |

| Base | Structural support | Concrete, asphalt |

For your project, balance aesthetics with durability and sustainability. For example, recycled glass aggregates offer a unique look while being eco-friendly. Polyurethane resin might be pricier but offers better UV resistance for outdoor use. Consider your specific needs, such as foot traffic or weather exposure, when making choices.

Technical Specifications

When laying resin bound gravel, consider these key factors:

- Aggregate type and size

- Resin quality

- Mix ratios

These elements are crucial for a long-lasting, attractive finish.

A solid sub-base, like tarmac, asphalt or concrete, is essential. Thoroughly clean and prepare the base for best results.

Mind the weather, too. Ambient temperature affects installation and curing times. Proper substrate preparation is vital.

With careful attention to these details, you’ll achieve a top-notch resin bound surface that’ll impress the neighbours and stand the test of time.

Material Requirements

Essential materials for a resin bound gravel surface:

- Resin: Choose a UV-stable, flexible type suitable for outdoor use.

- Aggregates: Clean, dry stones of the correct size.

- Base: A solid foundation like concrete or tarmac is crucial.

- Mixing ratios: Determine the right proportions of resin to aggregate.

- Layer depth: Calculate the appropriate thickness for your project.

Proper selection of these materials ensures a durable, long-lasting driveway.

Remember, skimping on quality can lead to costly repairs down the road.

For best results, consult a professional or thoroughly research each component before starting your project.

Resin Types and Properties

When it comes to resin bound gravel systems, choosing the right resin is crucial for a durable and high-performing surface.

Two main types are available: epoxy and polyurethane resins. Each offers distinct properties affecting:

- Colour stability

- Curing time

- Environmental impact

- UV resistance

- Flexibility

These resins contribute to the impressive durability of resin bound driveways, helping them withstand heavy traffic and resist wear and tear.

The seamless surface also prevents weed growth, moss, and algae, further extending the driveway’s lifespan.

When selecting your resin, consider these factors carefully.

Epoxy resins provide excellent strength, while polyurethane resins offer more flexibility.

Both have different curing times and environmental impacts, so choose based on your specific project needs.

For instance, if you’re installing a driveway in an area with frequent temperature changes, a more flexible resin might be best.

On the other hand, for a high-traffic commercial space, a stronger epoxy resin could be the better choice.

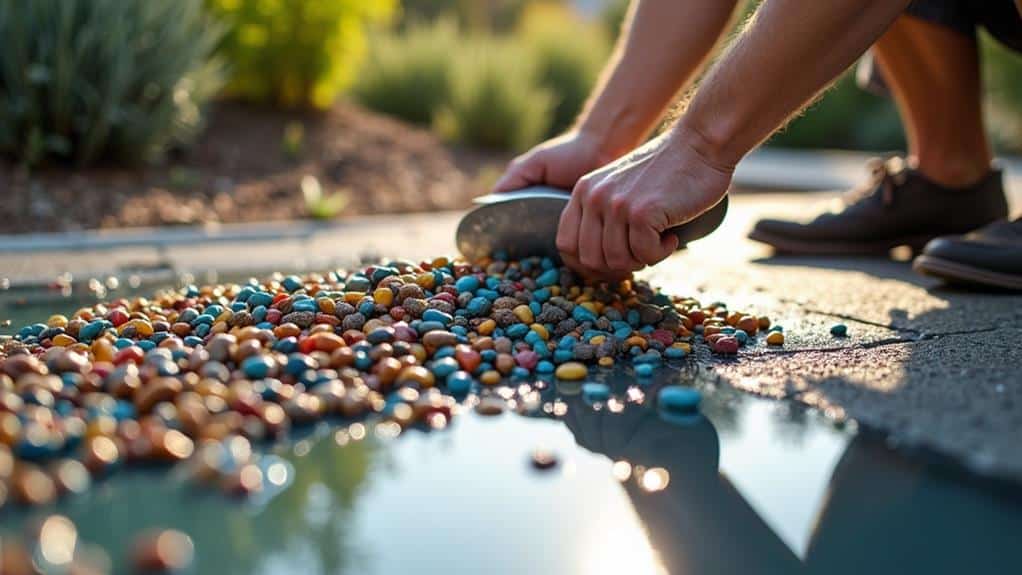

Aggregate Selection

Choosing the right aggregate is crucial for any resin bound gravel system. Consider various sources, ensuring they meet size and texture requirements that suit your design.

Colour variations significantly affect the final look. Think about the environmental impact of different options when selecting.

Pick aggregates not just for looks, but also for their durability and finish, ensuring a long-lasting, low-maintenance driveway. Opt for materials that are tough, visually appealing, and align with your project’s sustainability goals.

For instance, locally sourced aggregates might reduce transport emissions, whilst recycled glass could add a unique sparkle to your driveway.

Mixing Ratios

Getting the mix right is crucial for resin bound gravel. Master proper mixing techniques and ratio adjustments to ensure consistent application. Choose compatible materials and use the right mixing equipment. UV stable resin is key for long-lasting colour and durability. Proper mixing creates a permeable surface that meets SuDS standards.

- Mix 3 parts aggregate to 1 part resin by weight

- Adjust ratios for different aggregate sizes

- Mix thoroughly for 3-5 minutes

- Ensure all aggregates are fully coated

- Add pigments or additives as needed

Think of it like baking a cake – the right ingredients in the right amounts make all the difference. Too much or too little of anything can spoil the end result.

With practice, you’ll get a feel for the perfect mix.

Layer Depths

Resin bound gravel depth varies based on its intended use.

For foot traffic, aim for 15-18mm, whilst vehicle-heavy areas require 18-20mm. These depths ensure proper bonding and longevity.

When laying over a solid base like concrete or tarmac, maintain a consistent depth throughout.

For less stable areas, such as tree pits, increase the depth to 30-40mm for added stability.

Always ensure your base is suitable before installation to guarantee the best results for your resin driveway or path.

Recommended Resin Bound Gravel Layer Depths

Installation Parameters

When installing resin bound gravel, consider these key factors:

- Stable, well-prepared base

- Weather conditions (temperature and humidity affect curing)

- Proper ground preparation, including:

- Excavation

- Compaction

- Suitable sub-base material

Professional expertise is crucial for:

- Correct mixing ratios

- Proper application techniques

These elements ensure a durable, attractive finish.

Mind the British weather – a dry spell is ideal for installation.

Think of it like laying a patio; the foundation is just as important as the surface you see.

Base Requirements

A solid foundation is crucial for a successful resin bound gravel installation. Proper base preparation ensures long-lasting results.

Key factors to consider include:

- Subgrade stabilisation methods

- Drainage system integration

- Material layering strategies

- Environmental impact considerations

- Compaction requirements

Your base should be sturdy, level and well-draining. A compacted sub-base of MOT Type 1 aggregate, topped with a layer of tarmac or concrete, typically provides an ideal foundation.

Suitable bases include tarmac, asphalt and concrete, which offer stability and durability for resin systems.

It’s worth noting that block paving and paving slabs aren’t recommended due to their numerous joints and potential for cracking.

Weather Conditions

Weather conditions are crucial for successfully installing resin bound gravel systems.

Consider temperature, humidity and seasonal changes before starting your project. Professional contractors can assess specific site needs to ensure ideal installation conditions.

Avoid wet weather, as rain can hinder the curing process. Wind may affect resin mixing and application.

For best results, aim for dry weather with temperatures between 5°C and 30°C and low humidity.

Temperature Ranges

Temperature ranges are crucial for properly installing resin bound gravel systems.

Consider temperature effects and seasonal changes to ensure proper curing and adhesion. Thermal expansion can affect the final result, so timing is key. Always monitor temperature during installation. The curing process is greatly influenced by temperature, with warmer conditions speeding it up.

- Ideal installation range: 5°C to 30°C

- Avoid extreme heat or cold

- Higher temperatures speed up curing

- Lower temperatures slow down curing

- Allow materials to acclimate properly

For example, installing on a scorching summer day might cause the resin to set too quickly, whilst a frosty winter morning could prevent proper bonding.

It’s best to aim for a mild, dry day for optimal results.

Professional Expertise

Professional expertise is crucial for proper installation of resin bound gravel systems.

Consult experts to assess your project’s needs. Many suppliers offer training to boost your skills.

Certified installers know how to choose the right resin and prepare the ground for your driveway.

Experienced pros manage projects, ensuring they meet industry standards.

Good customer support is vital for sorting any snags during or after installation.

Design and Applications

Resin bound gravel is popular in various outdoor spaces across the UK, including driveways, patios, pool surrounds and garden paths.

Its flexibility allows for unique designs, such as curves, patterns or contrasting borders, enhancing your garden’s look.

Many installations use eco-friendly materials, offering both visual appeal and environmental benefits.

With a wide range of colours and textures available, you can personalise your space to suit your taste.

When planning, consider how different aggregate colours and sizes might complement your home’s architecture and existing outdoor features.

This versatile material is a practical and attractive choice for many British homeowners looking to improve their outdoor areas.

Common Applications

Resin bound gravel is widely used across the UK for a variety of purposes.

You’ll spot it on residential driveways and patios, as well as commercial car parks and walkways. It’s a popular choice for public spaces too, like park paths and town squares.

This versatile surfacing option is particularly favoured for its permeable qualities, meeting Sustainable Drainage Systems (SuDS) standards and getting the nod from the Environment Agency for flood prevention.

Whether you’re sprucing up your home or working on a large commercial project, resin bound gravel offers a practical and attractive solution for your surfacing needs.

Residential Uses

Resin bound gravel offers five key uses for homes, transforming outdoor spaces with style and practicality.

It’s a versatile option for sprucing up your property’s exterior, marrying form and function. Classic Stone Driveways, a Manchester-based company founded in 2019, specialises in these top-notch, long-lasting surfaces. Their eco-friendly materials ensure both kerb appeal and sustainability.

Popular applications include:

- Driveways

- Garden paths

- Landscaping features

- Patios

- Pool surrounds

Resin bound gravel can significantly boost your property’s appearance while providing hardy, low-upkeep surfaces.

It’s ideal for creating cohesive outdoor designs that complement your home’s aesthetic. Whether you’re after a smart new driveway or a charming garden path, this material offers a practical and attractive solution for UK homeowners.

Commercial Projects

British businesses are opting for resin bound gravel in commercial projects, prizing its durability and looks. When overseeing these projects, consider budget, safety rules and client wishes. Common applications include:

| Retail | Hospitality | Corporate |

|---|---|---|

| Car parks | Hotel drives | Office plazas |

| Walkways | Pool decks | Courtyards |

| Shopfronts | Patios | Rooftops |

| Shopping centres | Holiday resorts | University grounds |

This versatile material works brilliantly for high-traffic areas like supermarket car parks and hotel entrances. It’s also a smart choice for sprucing up office exteriors or creating inviting outdoor spaces at restaurants. With proper planning, resin bound gravel can transform any commercial space into an attractive, low-maintenance area that impresses clients and customers alike.

Public Spaces

Resin bound gravel is making a splash in public spaces across the UK, beyond just commercial use.

You’ll spot this versatile material enhancing:

- Parks and playgrounds

- Outdoor event spaces

- Pedestrian walkways

- Sports courts

- Urban plazas

Its durability, low upkeep, and smart look make it perfect for busy areas.

The UV-resistant qualities ensure it stays looking good, even in direct sunlight.

Resin bound gravel offers a safe, water-permeable surface that suits various settings while meeting accessibility rules.

It’s a practical choice for councils and planners looking to spruce up public spaces without breaking the bank.

Design Elements

When designing your resin bound gravel surface, you’ve got plenty of creative choices. Pick from various colours, textures, and patterns to craft a unique look.

Customisable colour palettes let you match your driveway to your home’s exterior for a consistent appearance. Adding lighting can boost both style and safety.

Consider edge treatments for a polished finish and smooth transition to nearby areas. For example, a warm honey-coloured gravel could complement a red-brick house, while embedded LED lights along the edges could guide you home on dark evenings.

Color Selection

Colour selection is crucial for your resin bound gravel project. Consider the psychology of colours and current trends when choosing your palette.

UV-resistant resins can help maintain vibrant colours and prevent fading. Experiment with different colour combinations to enhance aesthetics and complement your surroundings. Keep in mind that some hues may fade over time.

Options include:

- Natural earth tones

- Bold, contrasting colours

- Subtle, monochromatic schemes

- Vibrant, eye-catching hues

- Multi-coloured blends

Your colour choice will significantly impact the overall look and feel of your space.

For example, warm browns and greens can create a natural, inviting atmosphere, while bold blues or reds might add a modern touch. Choose wisely to achieve the desired effect for your project.

Texture Options

Texture is crucial for resin bound gravel surfaces, impacting both looks and function. You’ll find options from smooth to coarse.

These driveways offer a modern aesthetic, with various colours and finishes to boost your property’s kerb appeal. You can customise the surface through colour blending and pattern designs.

Adding tactile elements can provide visual interest and practicality. For instance, a slightly rougher texture might be ideal for areas with heavy foot traffic or steep inclines.

When choosing, consider both appearance and performance to suit your specific needs. The right texture can make all the difference in creating a driveway that’s not only stunning but also fit for purpose.

Pattern Possibilities

Resin bound gravel patterns offer a wealth of creative options for outdoor spaces.

Geometric shapes, artistic designs and bespoke motifs can transform driveways and patios.

Colour blends and textured finishes add depth, while customisable palettes ensure harmony with your home’s exterior.

Popular pattern choices include:

- Circular designs

- Herringbone layouts

- Flowing curves

- Contrasting borders

- Intricate mosaics

By combining colours, aggregate sizes and patterns, you can create unique surfaces that complement your property’s style.

A well-designed resin bound driveway can make your home stand out in the neighbourhood, adding both kerb appeal and value.

Edge Treatments

Edge treatments can make or break your resin bound gravel surface’s look. Borders are key to enhancing appeal.

Try brick, stone, or metal edging for clear boundaries. Colour options let you match your home’s exterior for a unified appearance. Adding patterns and textures can boost visual interest.

Proper installation ensures clean lines and durability. Consider maintenance when choosing edges, as some need more upkeep than others. For example, metal edging might need occasional rust treatment, while stone borders could require repointing.

In my opinion, a well-chosen edge treatment can transform a basic driveway into a standout feature of your property.

Performance Analysis

When assessing resin bound gravel, consider its structural qualities and safety features.

This surfacing option boasts impressive load-bearing capacity and crack resistance, making it suitable for various traffic types. Its exceptional durability and weather resistance ensure long-lasting performance in diverse conditions, from heavy foot traffic to extreme weather.

The non-slip properties enhance safety in wet conditions, making it ideal for driveways, paths, and pool surrounds.

For example, a resin bound gravel driveway can withstand the weight of multiple vehicles whilst remaining safe to walk on, even during a typical British downpour.

Structural Properties

When assessing resin bound gravel, it’s crucial to examine its structural properties. Key factors include load-bearing capacity, durability, weather resistance and UV stability.

These determine how well your surface will hold up under daily use and environmental stress. The permeable nature of resin bound gravel allows for effective water drainage, reducing puddles and flood risks.

This is particularly useful in Britain’s often rainy climate. For example, a well-installed resin bound driveway can withstand heavy vehicles and harsh weather for years, making it a sound investment for UK homeowners.

Load Bearing Capacity

Assessing the load-bearing capacity of resin bound gravel is crucial for its long-term performance.

You’ll need to analyse load distribution and weight capacity to determine its suitability. Key factors to consider include:

- Structural integrity

- Flexibility

- Load testing

- Expected traffic intensity

- Subbase strength needs

The choice of base material significantly affects the load-bearing capacity.

Macadam and concrete are solid options, providing stability for resin adhesion. Understanding these aspects will help you make smart decisions about your resin bound gravel installation, ensuring it can handle expected loads and keep its looks over time.

For example, a residential driveway might require less load-bearing capacity than a car park for a shopping centre.

It’s best to consult with a professional to determine the specific requirements for your project.

Durability Factors

Resin bound gravel’s durability depends on several key factors. When considering its longevity, think about environmental impact, looks, maintenance needs and weather resistance.

The porous nature of resin helps prevent cracking and wear, making it suitable for various British weather conditions. Proper installation and quality materials are crucial for withstanding UV rays, freezing temperatures and heavy foot traffic.

Regular cleaning and occasional resealing can extend its lifespan, ensuring your investment stays attractive and functional for years to come.

For example, a well-maintained resin driveway in Manchester could easily last 15-20 years, even with frequent use and exposure to rain and frost.

Weather Resistance

Resin bound gravel’s weather resistance is crucial for its structural performance. This surface excels in durability against various elements, offering:

- Freeze resistance in cold weather

- UV protection to prevent fading

- Effective moisture management

- Seasonal adaptation for year-round use

- Resilience against extreme temperatures

Permeable surfaces enhance natural water filtration and drainage, allowing rainwater to soak into the ground and reducing runoff into storm drains.

This feature helps prevent flooding and supports sustainable water management.

These qualities contribute to the longevity and reliability of resin bound gravel surfaces, making them a smart choice for outdoor installations across the UK’s diverse climate.

UV Stability

UV stability is crucial for the long-term performance of resin bound gravel surfaces.

Top-notch resins include UV protection to prevent colour fading and maintain appearance. UV-resistant resins are available, ensuring vibrant colours and durability, particularly in sunny areas.

Poor installation can worsen fading, so skilled application is vital. This resistance to environmental impact boosts the system’s longevity, reducing the need for frequent replacements.

Regular cleaning and sealing help maintain UV stability in your resin bound gravel installation.

Safety Features

When choosing resin bound gravel for your project, it’s crucial to assess its safety features. Key areas to consider include slip resistance, drainage efficiency, surface integrity and edge protection.

SuDS compliance is vital for maintaining driveway integrity and preventing flooding, making it an essential safety consideration.

Resin bound surfaces offer excellent permeability, allowing rainwater to drain naturally and reducing puddles.

These factors contribute to the overall safety of your resin bound gravel installation, ensuring a secure and long-lasting surface.

Slip Resistance

Slip resistance is crucial for outdoor surfaces, and resin bound gravel delivers on this front. Its inherent grip makes it ideal for various uses.

Anti-slip additives can be mixed in during installation to boost safety, particularly in areas that often get wet.

Resin bound surfaces offer:

- Reliable grip in all weather

- Better traction through slip-resistant materials

- Adherence to safety standards

- Long-lasting slip resistance

- Options for extra surface treatments

Testing ensures these surfaces meet or surpass required safety levels.

Drainage Efficiency

Resin bound gravel offers excellent drainage, a key advantage for UK properties. Its permeable surface lets water seep through, reducing runoff and preventing puddles. This clever design aids water management and lessens environmental impact.

These surfaces can handle impressive drainage rates of up to 850 litres per minute per square metre, effectively preventing flash floods.

The eco-friendly nature of resin bound gravel is noteworthy. It naturally filters pollutants and replenishes groundwater, contributing to sustainable practices.

For UK homeowners, this material is a smart choice to mitigate flood risks and comply with local regulations on permeable surfaces.

Surface Integrity

Resin bound gravel stands out for its surface integrity, offering top-notch safety alongside its good looks.

Its long-lasting performance and low upkeep make it a smart choice for UK homeowners. The strong bond with the ground underneath ensures it stays put and lasts longer.

The permeable design helps manage rainwater, reducing puddles and runoff – a real plus in our often wet climate.

Key benefits:

- Stays grippy even in the rain

- Doesn’t crack or suffer from frost

- Keeps its colour in the sun

- Eco-friendly

- Versatile – great for driveways and patios alike

Edge Protection

Edge protection is a crucial safety feature of resin bound gravel, building on its surface integrity benefits. Proper edge protection enhances both stability and visual appeal. When selecting edge protection, consider these key factors:

| Factor | Importance |

|---|---|

| Material | High |

| Width | Medium |

| Height | Medium |

| Colour | Low |

| Installation | High |

Correct installation techniques ensure long-lasting performance and reduce environmental impact. Choose edge protection that matches your overall design whilst prioritising safety. For instance, a sturdy aluminium edging might be ideal for a modern driveway, whereas a rustic stone border could suit a country garden path. Remember, the right edge protection not only looks good but also prevents gravel from spreading and maintains a clean, defined border.

Cost Evaluation

When weighing up resin bound gravel, you’ll want to look at its long-term value.

Compare the upfront costs with potential savings on upkeep and longevity. Getting quotes from several contractors will help you sort out your budget and make a fair comparison.

Prices usually vary based on the size of your project and any custom features you fancy.

Don’t forget to factor in how it might boost your property’s worth and kerb appeal.

It’s a bit like choosing between a cheap pair of trainers that’ll wear out quickly and a pricier pair that’ll last for ages – sometimes spending more at the start can save you a packet in the long run.

Investment Analysis

When weighing up resin bound gravel, you’ll need to crunch the numbers carefully. Your cost breakdown should cover materials, labour, long-term value, and upkeep.

Getting quotes from several contractors will give you a solid price comparison, helping you stick to your budget. Bear in mind that tricky installations or dodgy ground conditions could bump up the cost.

By considering all these factors, you’ll get a clearer picture of what you’re in for financially and whether it’s worth the investment.

Material Costs

When budgeting for a resin bound gravel installation, consider these key costs:

- Resin

- Aggregates

- Installation

- Maintenance

- Project scope

Resin prices vary by quality and brand, whilst aggregate costs depend on type and quantity needed. The two main resin types are polyurethane and epoxy, each with unique properties affecting price.

Installation costs cover labour and equipment. Don’t forget to factor in long-term upkeep expenses.

For a typical driveway, resin might cost £20-30 per square metre, with aggregates adding another £10-15. Labour often accounts for about half the total cost.

A small patio could set you back £1,000-£2,000, whilst a large driveway might cost £5,000-£10,000.

Installation Expenses

Installation costs make up a significant chunk of your resin bound gravel project budget.

When planning, get detailed quotes from several contractors. Each quote should break down costs for labour, equipment and any extras.

Professional installation is crucial for long-term durability and best results, so factor this in. More complex installations may cost more.

Consider finance options if needed. Keep tabs on all spending during the project to stay on budget.

This approach will help you manage installation costs effectively.

Long-term Value

Resin bound gravel driveways offer excellent long-term value.

They’re a sound investment, boosting property value and kerb appeal whilst cutting maintenance costs.

These driveways last longer than many alternatives, with their durability ensuring minimal repairs over time.

The porous surface improves drainage, potentially lowering insurance premiums and reducing water damage risks.

Key benefits:

- Increased property value

- Lower upkeep costs

- Extended lifespan

- Better kerb appeal

- Improved drainage

When weighing up driveway options, consider these factors to gauge the cost-effectiveness of resin bound gravel for your home.

Maintenance Budget

A solid maintenance budget is crucial when considering a resin bound gravel driveway as a long-term investment. Start by calculating upfront costs and forecasting future expenses.

Factor in the impact of British weather and regular cleaning needs. Conduct a thorough financial analysis to grasp the total ownership cost. Implement smart expense management to optimise your budget.

Regular cost reviews and budget planning will help you maintain your driveway efficiently whilst keeping long-term costs in check. For example, setting aside funds for annual deep cleaning and periodic resealing can prevent costly repairs down the line.

In my opinion, it’s better to overestimate slightly than be caught short when maintenance is needed.

Maintenance Protocol

Resin bound gravel surfaces need far less upkeep than traditional gravel driveways.

A regular sweep and the odd pressure wash will keep your driveway looking smart and weed-free. For top results, give it a thorough clean once a year with a pressure washer, but don’t go over 150 bar to avoid damaging the surface.

It’s crucial to tackle any spills or stains straight away to keep your driveway looking good and lasting longer.

Care Requirements

Care Requirements

To keep your resin bound gravel surface in top shape, follow these key steps:

- Regular cleaning: Sweep often to remove loose stones and debris. This maintains appearance and prevents damage.

- Seasonal maintenance: Tackle specific tasks each season, like removing fallen leaves in autumn.

- Professional services: Occasionally hire experts for deep cleaning or repairs.

- Preventive measures: Use protective mats in high-traffic areas and avoid heavy loads to extend the surface’s lifespan.

Regular Cleaning

How often should you clean your resin bound gravel surface? Set up a regular cleaning routine to keep it looking top-notch.

Use proper tools to remove dirt and prevent stains. Good care ensures your surface stays protected and lasts longer. Regular cleaning helps maintain its looks and spot any repair needs early on.

Steer clear of harsh chemicals that might harm the resin.

- Sweep weekly to clear loose bits

- Pressure wash every 3-6 months

- Clean spills straight away

- Apply sealant yearly

- Check for damage often

Seasonal Maintenance

The UK’s four seasons pose unique challenges for resin bound gravel upkeep. Perform seasonal checks to spot issues early.

Apply protective treatments in spring and autumn to guard against weather damage.

Winter prep involves clearing leaves and debris, whilst summer care centres on weed control and UV protection.

Regular sweeping and cleaning are vital year-round to keep your driveway looking smart and working well.

Adjust your maintenance routine seasonally; for instance, clean more often during high pollen months or after storms.

Professional Services

Professional Services for Resin Bound Gravel

Although resin bound gravel is relatively easy to maintain, professional services are crucial for ensuring your driveway’s longevity and appearance. These surfaces are highly durable and resist cracking, but proper care remains essential.

For both homes and businesses, professional services typically include:

- Installation training

- Maintenance

- Project advice

- Repairs and restoration

- Bespoke care plans

Expert services ensure your resin bound surface stays in top nick, tackling any issues quickly and effectively.

You’ll benefit from their specialist know-how and kit, getting the most out of your investment. Think of it like servicing your car – regular check-ups by pros can prevent costly problems down the road.

Preventive Measures

Proper daily care is crucial for maintaining your resin bound gravel surface, alongside professional services.

Establish a preventive maintenance routine, including regular sweeping and gentle washing. Frequent cleaning with a broom or pressure washer is essential, but steer clear of harsh chemicals that could damage the surface.

Apply protective treatments to guard against stains and UV damage. When planning long-term, consider environmental factors like tree roots and drainage.

For winter safety, implement de-icing methods that won’t harm the resin.

These simple steps will help keep your surface in top condition for years to come.

Installation Guide

To execute your resin bound gravel project effectively, follow these steps:

- Prepare the base surface thoroughly. Ensure it’s clean, dry and stable.

- Seek professional advice for proper base preparation and long-term durability.

- Mix the resin and aggregate as per the manufacturer’s instructions.

- Apply the mixture evenly across the prepared area.

Remember, a well-prepared base is crucial for a lasting finish, much like laying a solid foundation for a house.

Skipping steps or cutting corners might save time initially, but it’ll likely lead to headaches down the road.

Project Execution

When installing resin bound gravel, follow a systematic approach.

Begin with a thorough site assessment and surface prep to ensure a solid foundation. This typically involves clearing existing materials and creating a clean, level surface for optimal results.

Next, process the materials, apply the mixture using proper techniques, and allow adequate curing time.

This process yields a durable and attractive finish that’s perfect for driveways, paths, and patios across the UK.

Site Evaluation

A thorough site evaluation is crucial for a successful resin bound gravel project. Before starting, assess:

- Ground levels and slopes

- Drainage patterns

- Soil stability

- Environmental impact

- Current surface conditions

Examine the area’s topography, spot potential drainage issues, and check the soil’s strength.

Consider how your project might affect the local environment. This evaluation helps you plan effectively and avoid costly mistakes.

Ensuring SuDS compliance is vital for maintaining your resin driveway’s integrity and preventing flooding.

Proper drainage assessment contributes to the project’s sustainability and longevity.

Surface Preparation

With the site evaluation done, it’s time to prep the surface for your resin bound gravel installation.

Based on your assessment, start by ensuring proper surface grading and drainage. Clear away any debris or plants.

Get top-notch materials and the right kit for the job. If needed, fix or strengthen the base surface to ensure a solid foundation for the resin bound gravel system.

Material Processing

The mixing process is crucial for a top-notch resin bound gravel surface. Source materials carefully and follow proper aggregate processing methods.

Consider new resin trends and environmental impact when choosing components. Ensure timely delivery of materials to your site with efficient logistics.

Key points:

- Pick high-quality aggregates and resins

- Stick to manufacturer’s mixing ratios

- Use a forced action mixer for thorough blending

- Keep an eye on temperature and humidity whilst mixing

- Work swiftly to maintain the right viscosity

Application Methods

After mastering the mixing process, it’s time to apply your resin bound gravel mixture. Different techniques are needed for various surfaces. Consider these key factors:

| Factor | Consideration |

|---|---|

| Surface | Concrete, tarmac, or other |

| Weather | Temperature and humidity |

| Tools | Trowels, rollers, or spreaders |

| Thickness | Typically 15-20mm |

| Curing | Allow 24-48 hours for full cure |

Proper application and curing ensure durability, while regular maintenance keeps your resin bound surface looking smart and working well. For instance, a driveway might need different treatment than a garden path. Always check the weather forecast before starting – a rainy day could ruin your hard work!

Curing Process

Once you’ve applied your resin bound gravel mixture, proper curing is crucial for a long-lasting, durable surface.

Key factors to consider:

- Curing time: Allow 24-48 hours for initial set

- Temperature: Ideal range is 10-30°C

- Methods: Natural air drying or accelerated curing

- Humidity: High levels can extend curing time

- Materials: Use specialised curing compounds if needed

Remember, a well-cured surface will withstand foot traffic and weather conditions better, much like a properly baked cake holds its shape.

It’s worth taking the time to get it right.

Critical Considerations

When weighing up resin bound gravel for your project, it’s crucial to understand its limits.

This surface isn’t ideal for all uses, especially where heavy vehicles pass or temperatures swing wildly. Poor installation or subpar materials can cause cracks or fading over time.

For example, a busy car park or a sun-baked patio mightn’t be the best fit.

Keep these drawbacks in mind to make an informed choice and avoid costly mistakes down the line.

Limitations

When considering resin bound gravel, it’s crucial to understand its limitations. Weather restrictions, weight limits and specific installation needs can affect its suitability for your project.

Common issues include:

- Frost damage in cold climates

- Discolouration from UV exposure

- Cracking under heavy loads

Familiarise yourself with these potential problems to make an informed decision.

For example, if you’re planning a driveway for large vehicles, you might need to explore alternatives.

Weather Constraints

Weather constraints pose significant challenges for resin bound gravel installation in the UK.

It’s crucial to consider weather patterns, seasonal changes, temperature fluctuations and humidity levels when planning your project. Timing is key for optimal results.

Key weather constraints to watch out for:

- Extreme cold or heat

- Heavy rain or snow

- High humidity

- Sudden temperature drops

- Strong winds

These factors can affect curing time, adhesion and overall quality of your resin bound surface.

For instance, a sudden downpour during installation could wash away the resin, while a heatwave might cause it to cure too quickly.

In my opinion, it’s best to aim for mild, dry days to ensure the best outcome for your project.

Weight Restrictions

Weight restrictions are crucial when planning your resin bound gravel installation. Think about how traffic and load distribution might affect your surface’s strength. Test the material to ensure it can handle expected weights. Use this quick guide:

| Weight Type | Impact | What to Do |

|---|---|---|

| Pedestrians | Low | Standard install |

| Cars | Medium | Stronger base |

| Lorries | High | Get expert advice |

| Static loads | Varies | Ask a specialist |

For best results, consult a professional who can assess your specific needs and recommend the right approach for your project.

Installation Requirements

Installation requirements for resin bound gravel have several crucial limitations to consider:

- Tool needs

- Safety measures

- Site evaluation

- Surface types

- Prep methods

You’ll need specific tools and know-how to properly lay resin bound gravel.

Make sure you’ve thoroughly assessed the site, taking into account surface types and necessary preparation.

Strictly follow safety guidelines, as handling resin can be dangerous without proper precautions.

For instance, you might need a forced action mixer and a power float to ensure even mixing and application.

When evaluating the site, check for drainage issues or uneven surfaces that could affect the final result.

As for safety, always wear protective gear like goggles and gloves to avoid skin contact with the resin.

Common Issues

Common issues with resin bound gravel surfaces can crop up over time.

Shoddy installation or poor-quality materials might lead to cracks, loose stones, or bumpy areas.

The British weather can take its toll too, with UV rays potentially causing fading.

Neglecting regular cleaning can invite weeds and unsightly stains.

Poor design, like rubbish drainage, could result in puddles and damage.

It’s worth keeping an eye out for these problems to maintain your surface’s top-notch appearance and function.

Frequently Asked Questions

Can Resin Bound Gravel Be Installed Over Existing Concrete or Asphalt Surfaces?

Yes, resin bound gravel can be laid over existing concrete or asphalt. Proper preparation is crucial, though. Ensure the base is clean, stable and free from cracks or loose bits. The installation process is straightforward, but costs can vary depending on the area size and chosen finish. Maintenance is relatively low, requiring occasional sweeping and jet-washing. You’ll have plenty of colour and texture options to suit your taste, from a sleek modern look to a more traditional feel. Just remember, a well-prepared surface is key to a long-lasting, attractive result.

How Long Does It Take for Resin Bound Gravel to Cure Completely?

Imagine you’re waiting for the kettle to boil whilst your resin bound gravel sets. Typically, it takes 24-48 hours to cure fully. The exact time depends on temperature and humidity during installation. Warmer, drier conditions speed up the process, whilst cooler, damp weather slows it down. It’s best to avoid foot traffic during this period to ensure a proper finish.

Is Resin Bound Gravel Suitable for Areas With Frequent Freeze-Thaw Cycles?

Be wary of using resin bound gravel in areas prone to freeze-thaw cycles. Though tough, it might need more upkeep than you’d like. Consider other attractive options and weigh up the costs. Proper installation is crucial for lasting results. If you’re concerned about durability, it’s best to chat with a local expert who knows the ins and outs of your area’s climate.

Can Vehicle Oil Stains Be Removed From Resin Bound Gravel Surfaces?

Vehicle oil stains can indeed be removed from resin bound gravel surfaces. Use specialist cleaning solutions designed for this purpose. To maintain your surface, apply protective sealants and clean regularly. Tackle oil stains promptly to preserve the appearance and longevity of your resin bound gravel. For best results, consider seeking advice from a professional cleaning service familiar with these surfaces.

Are There Any Eco-Friendly or Recycled Material Options for Resin Bound Systems?

Many Britons now favour eco-friendly products, and resin bound systems are no exception. Sustainable options are available, offering both environmental benefits and unique aesthetics. These systems use recycled materials like crushed glass or reclaimed aggregates, blended with plant-based resins. Installation methods remain similar to traditional systems, and maintenance is straightforward. For example, a driveway made with recycled glass aggregate might sparkle in sunlight, adding visual interest whilst reducing waste. These eco-friendly alternatives perform well and can be just as durable as conventional options, making them a smart choice for environmentally conscious homeowners.

Conclusion

Right, you’re now clued up on resin bound gravel systems. From design to fitting and upkeep, you’ve got the knowledge to make a smart choice. These surfaces aren’t just good-looking; they’re practical too. Did you know resin bound surfaces can lower urban heat by up to 4°C? By opting for this eco-friendly choice, you’re not only sprucing up your property but also helping create a cooler, greener environment. It’s a cracking deal, really.

How can you banish stubborn moss from your tarmac driveway? Discover effective methods, from manual scraping to chemical treatments, and Read more

Stained tarmac driveway ruining your curb appeal? Discover effective techniques to tackle even the toughest blemishes and restore your driveway's Read more

Improve your tarmac driveway's appearance and longevity with our comprehensive guide, covering essential cleaning techniques and maintenance tips that will