Blacktop, made from asphalt, is best for low-traffic areas like residential driveways due to its higher stone-to-bitumen ratio. Tarmac, which contains more bitumen, is stronger and designed for high-traffic situations such as airport runways. While blacktop offers better traction in wet conditions, it requires regular maintenance. In contrast, tarmac is more durable under heavy loads but needs frequent repairs. Knowing these differences helps you choose the right material for your project, ensuring a smart decision.

Table of Contents

ToggleKey Takeaways

- Blacktop is an economical bituminous mix suitable for low-traffic areas, whereas tarmac is robust and made for high-traffic locations, such as airports.

- Blacktop has a higher stone-to-bitumen ratio, which boosts its strength, while tarmac has more bitumen, allowing it to better withstand heavy loads.

- Blacktop is mixed at higher temperatures, giving it a lighter finish, while tarmac is smoother and more polished.

- Blacktop provides better traction in wet conditions due to its rough texture, while tarmac, although smoother, offers less grip.

- Blacktop requires more regular maintenance because of its porous nature, while tarmac can struggle with durability when subjected to heavy traffic.

Definition and Common Uses

When it comes to paving surfaces, it's important to understand the differences between blacktop and tarmac.

Blacktop, a bituminous mixture primarily made of asphalt, is commonly used for residential projects like driveways and local roads due to its performance and low maintenance needs. In fact, blacktop is used in various road constructions, highlighting its versatility.

On the other hand, tarmac, a term widely used in the UK, is known for its durability and is best suited for high-traffic areas such as airport runways and major roads.

The choice between these materials often depends on regional preferences; blacktop is more commonly used in the U.S., while tarmac is the go-to in the UK.

Blacktop is generally more cost-effective for areas with less traffic, while tarmac's strength makes it ideal for industrial and military applications.

Ultimately, selecting the right material reflects various construction standards and environmental factors.

Composition and Materials

Although blacktop and tarmac share similar basic components, their compositions differ significantly, affecting their uses and performance.

Blacktop generally has a higher stone-to-bitumen ratio, incorporating various aggregates like crushed stone, gravel, and sand. This increased aggregate content enhances its strength and stability, while the bitumen acts as a crucial binder, providing flexibility and durability. Additionally, blacktop is often produced using hot mix asphalt concrete, which is suitable for high-traffic applications.

On the other hand, tarmac contains more bitumen, which improves its ability to withstand heavy traffic and environmental wear. Fillers such as limestone and fly ash are often added to both materials to enhance surface smoothness and longevity.

Understanding these composition differences is key to selecting the right material for your needs, whether for driveways or busy roadways.

Temperature and Mixing Process

When looking at the temperature and mixing process of blacktop and tarmac, it's important to note that blacktop is mixed at a higher temperature of around 150°C (300°F). This elevated temperature improves its flexibility and workability. Such differences in mixing temperatures affect the durability and adaptability of each material. Understanding these distinctions is crucial for selecting the right material for various uses, whether it be for roads, driveways, or parking areas. Additionally, it's essential to consider how hot pavement can pose risks to both pets and humans during warm weather.

Mixing Temperature Differences

Understanding the temperature differences in mixing blacktop and asphalt is crucial for effective paving.

Blacktop is usually mixed at higher temperatures, around 150°C, which enhances its flexibility. In comparison, asphalt typically mixes between 120°C and 150°C, depending on the specific application.

The mixing methods can influence the final surface characteristics. For example, using a higher mixing temperature for blacktop can result in a lighter, more reflective surface due to the increased use of aggregate.

On the other hand, asphalt needs to be compacted before it cools below 85°C to ensure proper density and avoid damage.

These temperature variations play a significant role in achieving the desired durability and performance of your paving projects.

Impact on Material Properties

The differences in material properties between blacktop and asphalt arise from their distinct temperature and mixing processes.

Blacktop has a higher stone-to-bitumen ratio, which enhances its malleability and durability. In contrast, asphalt contains more bitumen, making it more resilient and providing a smoother surface.

The quality of aggregates used is also important; asphalt typically employs higher-quality aggregates, resulting in better overall performance.

- Blacktop is easier to repair due to its composition.

- Asphalt's lower porosity offers greater durability against water damage.

- The type of aggregate directly affects strength and resistance to wear.

Understanding these differences is vital for making informed decisions in construction and maintenance, especially when considering traffic demands and environmental conditions.

Application Suitability Factors

While both tarmacadam (commonly known as blacktop) and asphalt serve similar purposes in paving, their suitability for different applications varies significantly based on temperature and mixing processes.

Tarmacadam is heated to around 150 degrees Celsius and has a higher stone-to-bitumen ratio, making it more flexible. This makes it ideal for driveways and parking lots, where ease of repair is important, particularly in low-traffic areas.

On the other hand, asphalt, typically heated to about 120 degrees Celsius, is designed for durability and can support heavier loads, making it better suited for high-traffic environments like roads and motorways.

The specific heating requirements and material properties of each option greatly affect their performance in various situations, so it's essential to choose based on your specific needs.

Appearance and Texture

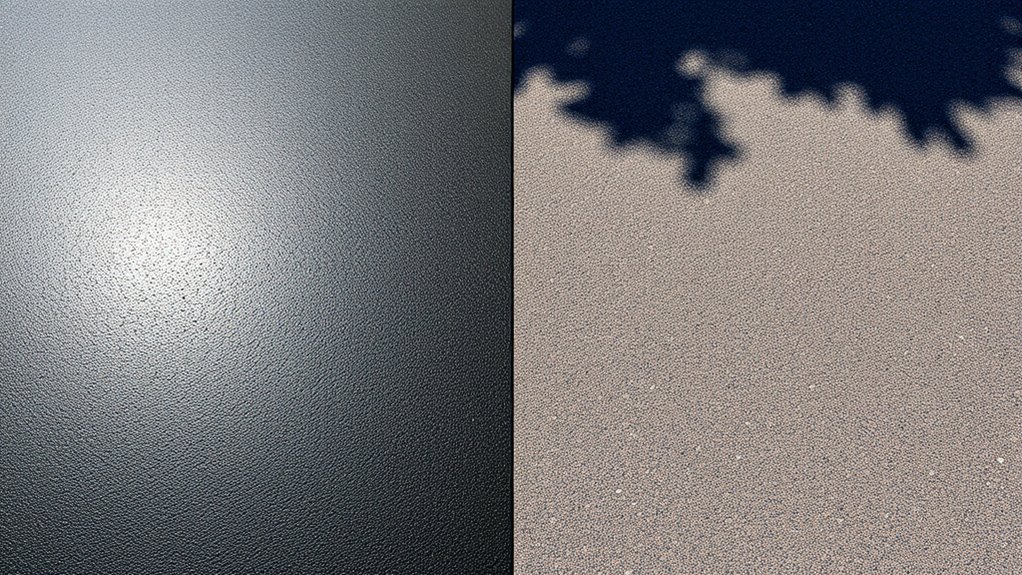

When comparing blacktop and tarmac, there are clear differences in texture, appearance, and grip.

Blacktop has a rougher surface that provides better traction, especially in wet conditions, making it a safer option for roads and driveways.

In contrast, tarmac has a smoother, more polished look, which can be visually appealing but mightn't offer the same level of grip.

These differences not only influence aesthetics but also the functionality of each material in various settings.

Surface Roughness Comparison

When comparing the surface roughness of blacktop and tarmac, it's important to recognise that their different compositions influence their texture.

Blacktop, which has a higher stone content, tends to be coarser, while tarmac offers a smoother finish. This variation affects roughness measurements, as the rougher surface of blacktop can impact vehicle traction and comfort.

- The higher stone content in blacktop contributes to more wear and increased roughness.

- Tarmac, with its tar binder, provides a smoother surface but is generally less durable.

- Regular maintenance can help preserve the surface texture and reduce roughness.

Understanding these differences is crucial for choosing the right material based on specific traffic and environmental conditions.

Visual Aesthetics Differences

The visual aesthetics of blacktop and tarmac differ significantly due to their unique compositions and application methods.

Blacktop often displays more noticeable colour variations, appearing darker with a glossy finish because of its higher stone content. Tarmac, on the other hand, has a smoother and more uniform appearance.

In terms of surface texture, blacktop provides a more textured finish, showcasing visible stones that enhance its visual appeal, whereas tarmac remains consistently smooth.

Over time, both surfaces may lighten due to weather exposure, but blacktop's stone visibility persists, contributing to its polished look. This difference in appearance makes blacktop a popular choice for residential areas, offering a neat, dark finish that boosts curb appeal.

Traction and Safety

Traction and safety are essential when choosing between tarmac and asphalt surfaces. Tarmac's rough texture significantly enhances traction, making it a safer option for both vehicles and pedestrians. Its higher stone content provides better grip, particularly in wet conditions, which reduces the risk of slipping.

- Tarmac is well-suited for residential areas due to its safety features.

- The rough surface offers improved footing for pedestrians, lowering the risk of accidents.

- While asphalt may be quieter due to its smoothness, it compromises on traction.

In places with heavy foot traffic or challenging weather, tarmac's texture is particularly beneficial. Although asphalt may be more durable for heavy traffic, tarmac's superior traction and safety make it the preferred choice for residential and lighter traffic situations. Additionally, tarmac's rough texture contributes to its effective performance in various weather conditions, enhancing safety further.

Durability and Maintenance

Understanding the differences in durability and maintenance between blacktop and tarmac is crucial for making informed decisions about paving materials.

Blacktop, made from crushed stone, is ideal for lighter traffic and provides a smooth finish. However, it requires regular maintenance, including more frequent sealing and crack filling due to its porous nature, which can enhance its lifespan.

In contrast, tarmac, which uses a tar binder, may struggle under heavy loads and is less durable overall.

Asphalt is generally more robust but also requires proactive maintenance to avoid significant damage. Sealcoating is beneficial for both blacktop and tarmac, helping to protect against water damage.

Cost Comparison

When comparing costs, blacktop and asphalt have similar initial investments, but their long-term financial implications can vary significantly. Prices for both materials can fluctuate based on installation methods, labour, and local market conditions.

- Blacktop typically costs between £25 and £55 per square metre, while asphalt can go up to £100 per square metre.

- Installation costs for asphalt driveways usually range from £2,500 to £6,000, depending on size.

- Additional expenses, such as site grading and complex designs, can significantly impact the overall costs.

While initial costs may appear similar, asphalt generally offers better durability and lower maintenance, which can provide greater long-term value.

Application Suitability

Both blacktop and tarmac are effective paving materials, but their suitability differs based on traffic conditions and environmental factors.

Blacktop is versatile and ideal for driveways, car parks, and playgrounds, as it can handle moderately heavy loads with minimal upkeep.

On the other hand, tarmac is better suited for minor roads and low-traffic areas, as it tends to struggle under heavy weight.

In high-traffic environments, blacktop's higher stone content provides better grip and durability.

Tarmac, due to its structural weaknesses, requires frequent repairs, especially in urban areas.

Therefore, choosing the right material depends on understanding these key differences in application suitability, as well as considering long-term maintenance costs associated with each option.

Frequently Asked Questions

Can Blacktop and Tarmac Be Recycled?

Yes, both blacktop and tarmac can be recycled through different processes, promoting sustainability. Methods like hot mix and cold in-place recycling help save resources while ensuring the materials remain strong for future use.

How Long Does Each Material Typically Last?

When comparing lifespans, blacktop surfaces usually last a few years, while tarmac can endure between 15 to 25 years. Maintenance and proper installation are key factors that significantly impact the durability and longevity of each material.

What Are the Environmental Impacts of Blacktop and Tarmac?

When paving with blacktop or tarmac, it's important to consider sustainability and pollution. Both materials lead to resource depletion, increased water runoff, and poorer air quality, all of which can negatively affect local ecosystems and future generations. For example, the heat generated by these surfaces can contribute to urban heat islands, making cities warmer and impacting wildlife. It's essential to weigh these environmental impacts when choosing paving materials.

Are There Color Options Available for Blacktop and Tarmac?

There are limited colour options available for blacktop and tarmac. The standard choices are usually black or dark grey. However, you can enhance the appearance with coloured coatings, though these may not be as durable as the original surfaces.

How Do Weather Conditions Affect Blacktop and Tarmac Installation?

Weather plays a crucial role in the installation of blacktop and tarmac. Cold temperatures can hinder the process, making it difficult for blacktop to set properly. Similarly, moisture can compromise both materials, affecting their strength and longevity. It's important to plan your projects around suitable weather conditions to ensure the best results. For example, aim for dry days with moderate temperatures to achieve a solid finish.

Conclusion

In summary, knowing the differences between blacktop and tarmac can aid in making the right choices for your paving projects. Approximately 94% of roads in the UK are surfaced with asphalt, predominantly consisting of blacktop. This underscores the importance of blacktop in our infrastructure, whereas tarmac is primarily used in specific settings, such as airports. By considering their composition and durability, you can ensure you select the appropriate material for your needs.

Prepare the perfect base for your resin bound stone installation and discover the crucial factors that ensure lasting durability.

Know where resin bound surfacing can transform spaces for both residential and commercial use, and discover the countless benefits that Read more

A stone carpet combines beauty and resilience in flooring, but what makes quartz floors uniquely beneficial? Discover the secrets behind Read more