Choosing the right base for your driveway is crucial for ensuring durability, stability, and effective drainage. Your options include crushed stone, gravel, concrete, and quarry process, each with its own advantages. Gravel is a cost-effective choice, but be prepared for ongoing maintenance. Concrete, while more expensive, offers excellent durability.

Ensure your base thickness is adequate—typically 100mm for gravel and 150mm for concrete. Proper grading and drainage systems are vital to prevent erosion and prolong the lifespan of your driveway. Keep reading to learn more about specific materials and their effects.

Table of Contents

ToggleKey Takeaways

- Crushed stone is an excellent choice for driveway bases as it offers great drainage and enhances the overall appearance of your property.

- Base thickness is vital: aim for at least 100mm for gravel and 150mm for concrete to ensure your driveway is stable and well-supported.

- Implementing effective drainage systems, like French drains, is crucial to prevent erosion and preserve the integrity of your driveway, particularly in wetter areas.

- Compacting the base material boosts durability and reduces the risk of cracking. Using mechanical equipment will yield the best results.

- Always take into account local soil conditions and climate when choosing materials and determining base thickness to maximise the longevity and performance of your driveway.

Types of Base Materials for Driveways

When choosing a base for your driveway, there are several materials to consider, each with its own advantages.

Crushed stone is excellent for drainage and compaction, available in various sizes and colours to enhance appearance. Proper selection prevents issues like cracking, sinking, and shifting, ensuring a smooth and durable driveway. A solid sub base is vital for ensuring durability in resin driveway installation.

Gravel offers a natural look and is easy to install, but requires upkeep to prevent movement.

Concrete is highly durable and provides a smooth finish, allowing for customisation, though it tends to be pricier to install.

Quarry process, or crusher run, combines crushed stone and dust for added stability, making it particularly suitable for colder climates.

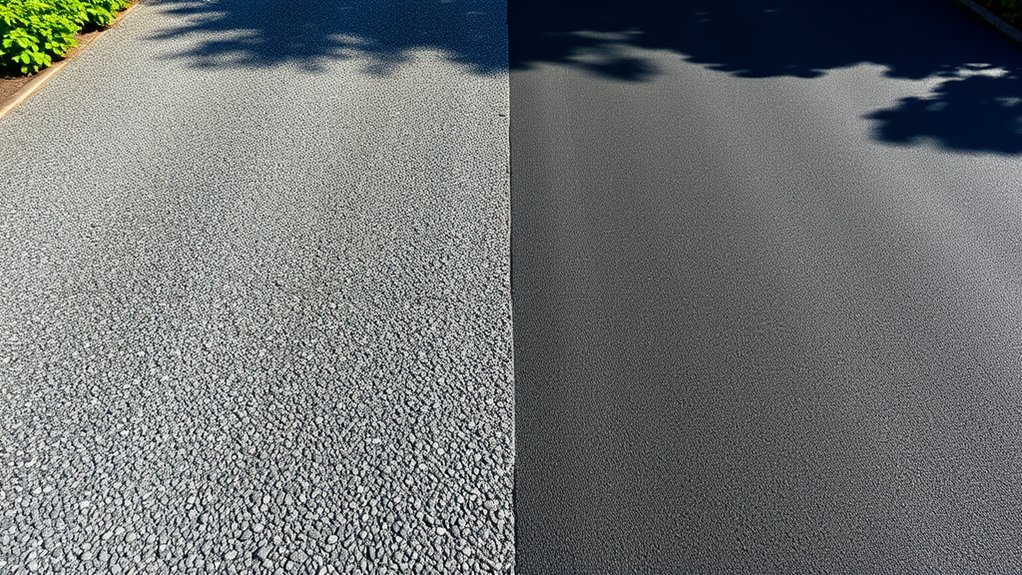

Asphalt provides a weather-resistant surface, often at a lower cost than concrete, but does need periodic maintenance.

Comparing these materials will help you find the best fit for your needs.

Characteristics and Benefits of a Good Driveway Base

Choosing the right base material is essential for a long-lasting driveway, but knowing its characteristics and benefits is just as crucial. A good driveway base provides stability and support, effectively distributing weight to prevent sinking or cracking. Its ability to drain water reduces the risk of erosion, while durability ensures it lasts over time. A strong load capacity allows it to support heavy vehicles without issue. Additionally, a well-constructed base is vital for road stability, improving the overall look of your driveway and allowing for various surface materials. This means less maintenance and lower repair costs in the long run. Ultimately, investing in a quality base boosts your driveway’s structural integrity, keeping it functional and attractive for years to come. The use of macadam as a binder course material is particularly beneficial for creating a stable foundation.

Thickness and Installation Considerations

When choosing the right base thickness for your driveway, it’s important to consider the material and the weight it will bear. Ensure proper grading and compaction to maintain stability and avoid future settling. Following recommended thickness guidelines will improve the longevity and effectiveness of your driveway. For instance, a typical gravel driveway may need a base of at least 100mm, while a concrete driveway might require 150mm for optimal support. For residential driveways, a minimum thickness of 2-3 inches of asphalt is recommended to ensure durability. Additionally, using a stable sub-base is essential for ensuring the resin driveway’s long-lasting performance.

Recommended Base Thickness

A well-planned base thickness is crucial for the durability and stability of your driveway. Here are the recommended base thickness guidelines based on the type of driveway:

| Driveway Type | Recommended Base Thickness |

|---|---|

| Residential Driveways | 100 to 150 mm |

| Commercial Driveways | 150 to 200 mm |

| Asphalt Driveways | 100 to 150 mm |

| Concrete Driveways | 150 to 200 mm |

For heavy-duty applications, you might want to exceed 200 mm. It’s important to choose the right thickness to support the weight of vehicles and avoid settling issues later on. Always consider the soil conditions and local climate when deciding on the appropriate base thickness for your needs. This careful planning will help ensure you have a long-lasting driveway.

Grading and Compaction Techniques

To ensure a durable and stable driveway, proper grading and compaction techniques are crucial during installation.

Start by grading the area with a slope of between 2% and 5% away from any buildings to allow for effective drainage. Clear away any organic matter and debris from the subgrade to establish a solid foundation.

Use mechanical equipment for compaction to achieve the required density, compacting in layers for even results. After compacting, proof roll the surface to spot any soft areas.

Use well-graded aggregates for added stability, making sure each layer is fully compacted before adding the next. Lastly, keep the moisture content at an ideal level to improve compaction effectiveness and minimise future settling, ensuring a strong base for your driveway.

Durability and Longevity Factors

When selecting a base for your driveway, opt for materials that resist erosion and can handle environmental challenges.

Ensuring proper compaction and stability is crucial for the long-term integrity of your driveway. By choosing high-quality materials in these areas, you can significantly improve its durability and lifespan.

For instance, gravel or compacted stone can provide excellent support and drainage, making them reliable options.

Erosion Resistance Materials

When selecting the best base for a driveway, understanding erosion-resistant materials is crucial for durability and longevity.

Both asphalt and concrete have their own advantages:

- Asphalt: Its flexibility makes it resilient against freeze-thaw cycles. The dark surface also helps melt snow and ice, reducing water pooling.

- Concrete: With proper sealing, concrete can last over 30 years, but it’s vital to prevent water from penetrating it.

Proper drainage and maintenance are essential for both materials to prevent cracking.

Crushed aggregate bases improve erosion control thanks to their interlocking particles. Pavers can also offer added durability and stability, especially during harsh weather, provided they’re well-maintained.

Choosing the right materials will enhance your driveway’s erosion resistance and extend its lifespan.

Compaction and Stability Importance

Understanding compaction and stability is vital for ensuring your driveway lasts. Effective methods like mechanical compaction using rollers and vibratory plates enhance soil stability.

Techniques such as dynamic and vibro-compaction can reach deeper soil layers, improving load-bearing capacity.

Proper compaction reduces air voids, boosts soil shear strength, and decreases the risk of settlement, resulting in a stable surface that resists cracking and buckling.

It’s also important to consider moisture content and layer thickness during compaction, as these factors significantly impact performance.

Cost and Environmental Impact

Choosing the right base for your driveway requires careful consideration of both costs and environmental effects, as these will impact your investment over time.

Here’s a straightforward cost comparison of your options:

- Gravel: £1-£3 per sq ft. It’s eco-friendly but requires regular upkeep.

- Asphalt: £3-£7 per sq ft. While it’s durable, it’s made from petroleum.

- Concrete: £3-£18 per sq ft. It can be sustainable, but has environmental consequences.

- Pavers: £10-£30 per sq ft. They offer design flexibility and can have environmental benefits.

- Shell: £0.50-£4 per sq ft. It’s inexpensive but not very durable.

Performance in Various Climates and Conditions

When choosing a driveway base, it’s important to consider how drainage in cold climates affects performance, particularly during freeze-thaw cycles.

For instance, if water seeps into cracks and then freezes, it can cause significant damage. To prevent erosion and maintain structural integrity, implement proper drainage solutions.

Additionally, keep in mind that regular seasonal maintenance can greatly extend the life and effectiveness of your driveway base.

Drainage in Cold Climates

As temperatures drop, effective drainage in cold climates is essential for preserving the integrity and safety of driveways.

Implementing strong drainage solutions ensures water doesn’t pool and freeze, which can create hazards. Here are some key considerations for winter maintenance:

- Material Selection: Choose materials that are resistant to cold to improve durability.

- Slope Design: Ensure the driveway has the correct slope for efficient water runoff.

- Freeze-Proof Options: Look into using slot drains to reduce ice formation.

- Debris Management: Regularly clear leaves and other debris from drain openings to keep them functioning properly.

- Insulation: Insulate drainage components to prevent ice build-up.

Erosion Prevention Strategies

To effectively tackle erosion, it’s vital to implement strategies tailored to your local climate.

In regions with heavy rainfall, installing French drains and trench drains can enhance drainage and prevent erosion. For drier areas, soil reinforcement methods like stabilisation mats can be beneficial.

In flood-prone locations, consider higher-capacity drainage systems to effectively manage excess water. Additionally, proper grading techniques, such as creating a slight slope away from the driveway, can help direct water flow and reduce erosion.

Using permeable pavers not only aids erosion control but also improves water quality by minimising runoff.

Seasonal Maintenance Requirements

Seasonal maintenance of driveways is crucial for ensuring their longevity and performance in varying UK climates.

To keep your driveway looking good and functioning well, follow this maintenance schedule:

- Spring: Check for cracks and apply sealants to prevent water damage.

- Summer: Clean regularly and watch for stains and algae growth.

- Autumn: Remove leaves and debris to avoid water pooling.

- Winter: Repair any cracks before the frost sets in; be mindful of de-icing products to avoid damage.

It’s important to note that different climates require tailored approaches.

In colder regions, focus on the effects of freeze-thaw cycles, while in hotter areas, ensure proper sealing against the heat.

Good drainage is vital in wet regions to prevent erosion.

Crushed Stone: The Reliable Choice

When selecting a reliable base for your driveway, crushed stone is a strong option. Made from mechanically crushed rocks like limestone and granite, crushed stone boasts exceptional durability.

The angular edges of the stones interlock, creating a stable base that can handle heavy traffic without significant wear.

In terms of appearance, crushed stone comes in various colours and sizes, allowing you to enhance your property’s curb appeal. Its porous nature also facilitates effective drainage, helping to prevent water pooling and reducing erosion.

While proper installation techniques are necessary, the low maintenance and long-lasting performance of crushed stone make it a practical choice for driveways. With minimal need for replacement, it’s a wise investment for your home’s exterior.

Quarry Process: Strength and Stability

Quarry process is an ideal material for driveways due to its exceptional strength and stability.

Here are some key benefits of using quarry process:

- Structural Integrity: It can support heavy vehicles without shifting.

- Compaction: Creates a stable base that resists erosion.

- Load Capacity: Effectively handles heavy loads and traffic.

- Weather Resistance: Endures various weather conditions without deterioration.

- Durability: Maintains its structure over time, minimising maintenance.

Choosing quarry process for your driveway ensures a low-maintenance surface that compacts well, providing a solid foundation.

Its durability makes it suitable not just for driveways, but also for other construction and landscaping projects.

CA6 Road Mix: A Versatile Option

While quarry process offers excellent strength and stability for driveways, CA6 Road Mix provides a versatile alternative suitable for various applications. Its composition of crushed stone particles improves compactability, making it ideal for everything from driveways to parking lots.

| Feature | CA6 Road Mix | Benefits |

|---|---|---|

| Density | 3,100 kg/m³ | Supports heavy loads |

| Coverage | 20 m² at 50 mm depth | Efficient for larger areas |

| Durability | Withstands traffic and weather | Long-lasting, low maintenance solution |

Gravel Bases: Cost-Effective but Maintenance-Heavy

Gravel driveways are an attractive option for homeowners looking for budget-friendly solutions, but they require significant upkeep.

While the initial costs are low, ongoing maintenance can add to your overall expenses. Here are the main tasks you’ll need to consider:

- Regular raking to prevent wheel ruts

- Refreshing the top layer for appearance and functionality

- Compacting to prevent settling

- Clearing debris to ensure easy access

- Regular checks to spot potential problems

Being aware of these maintenance needs is crucial for making an informed choice.

Although gravel driveways are economical, be ready for the effort needed to keep them in good shape.

Recycled Concrete: An Eco-Friendly Alternative

When considering options for your driveway base, recycled concrete is a great eco-friendly choice. It helps reduce construction waste that would otherwise go to landfill, supporting sustainable building practices.

By using recycled materials, you conserve natural resources like gravel and sand, which lessens the environmental impact associated with mining.

Recycled concrete compacts well, providing a solid base that can handle heavy loads and harsh weather, ensuring it lasts over time. It’s also more affordable than traditional materials and requires little maintenance.

Moreover, its excellent drainage properties help prevent erosion, making it a practical option.

Choosing recycled concrete contributes to a circular economy, making it a responsible selection for your driveway while promoting environmentally friendly construction methods.

Frequently Asked Questions

How Do I Choose the Right Base Material for My Driveway?

To select the right base materials for your driveway, first consider your budget and how you intend to use the space. Aim for a base thickness of 100-150mm for adequate stability. Don’t forget to factor in drainage and maintenance needs, which can vary based on your local climate and the amount of traffic your driveway will see. For example, if you live in an area with heavy rainfall, proper drainage is essential to prevent water pooling.

Can I Install a Driveway Base Myself, or Hire a Contractor?

When considering DIY driveway installation, it’s important to weigh the pros and cons. A professional contractor can bring expertise and efficiency, potentially saving you time and hassle. However, if you have the right skills, you might manage it yourself. For example, laying a simple gravel driveway could be a manageable task for a keen DIYer, while a block paving project might be better suited to a professional.

What Tools Do I Need for Installing a Driveway Base?

For installing a driveway base, you’ll need some key tools: shovels, wheelbarrows, and a plate compactor. It’s also advisable to use a grader scraper for an even surface, and geotextile fabric to enhance stability and prevent weeds from coming through.

How Long Does It Take to Install a Driveway Base?

Installing a driveway base usually takes between 1 to 2 days, depending on the size and quality of the soil. Key preparation steps, such as excavation and compaction, play a significant role in determining the installation time and the stability of the driveway. For instance, if you have clay soil, it may require more effort to prepare compared to sandy soil, potentially extending the timeframe.

What Are Common Mistakes to Avoid When Laying a Driveway Base?

Laying a driveway base carelessly is like constructing on unstable ground. Ensure proper compaction of the base and pay attention to drainage to prevent settling and erosion. Don’t overlook soil testing; it’s crucial for a solid foundation.

Conclusion

Selecting the right base for your driveway is crucial for stability and durability, not just how it looks. Consider materials like quarry process or CA6 road mix, which provide strength and longevity while also being cost-effective. Many homeowners miss the advantages of recycled concrete, an eco-friendly alternative worth exploring. Remember, the right foundation ensures a smoother, more resilient driveway that can handle everyday wear and tear.

Beneath the surface of tarmac and asphalt driveways lies a world of differences; discover which option suits your needs best.

Choosing between a tarmac and resin driveway can be challenging; discover the key factors that could influence your decision.

Not sure how long a tarmac driveway installation takes? Discover the essential steps and timelines that could surprise you.