For heavy vehicles, concrete is the best option due to its strength and durability. It can handle significant loads without cracking, especially when reinforced and installed correctly. While asphalt might be cheaper initially, it softens in warm weather and isn’t as sturdy under heavy use. Concrete has a lifespan of up to 30 years, needs less maintenance, and generally performs better. Consider how other materials measure up to determine what suits your needs best.

Table of Contents

ToggleKey Takeaways

Concrete is the best choice for driveways used by heavy vehicles due to its strength and durability. It can handle significant loads without bending or deforming. For regular heavy use, reinforced concrete with a compressive strength of 5,000 PSI or higher is recommended.

While asphalt is a more economical option, it can deform in high temperatures, making it less reliable for heavy traffic. Proper installation and maintenance are key; when installed correctly, concrete generally outlasts asphalt.

Make sure your driveway design adheres to specifications for width, turning radii, and throat width to avoid congestion and potential damage.

Understanding Heavy Vehicle Requirements

When designing a driveway for heavy vehicles, it’s crucial to consider their specific needs for durability and safety. Heavy vehicle specifications require that your driveway can bear significant loads without cracking or deforming. Reinforced concrete is usually the best option due to its strength. Ensure the subbase is well-compacted to evenly distribute weight and handle the dynamic forces from acceleration and turning. The design of the driveway’s geometry is important; widths should be between 6 and 12 metres, with turning radii of at least 7.5 metres for safe manoeuvring. A minimum throat width of 6 metres will help prevent congestion. Additionally, properly built tarmac driveways can also support heavy vehicles if designed with adequate thickness and compaction.

Asphalt Driveways: Pros and Cons

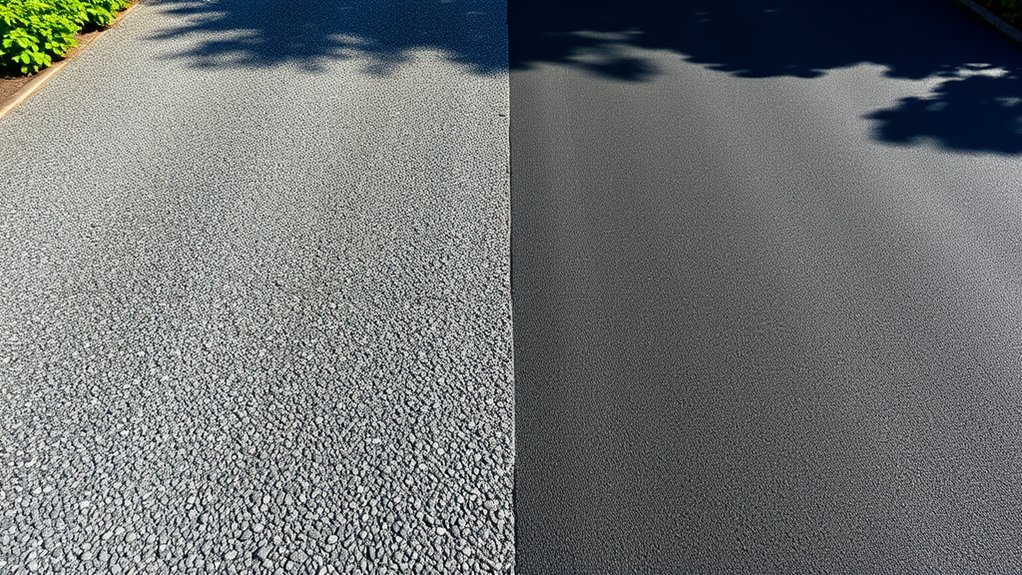

Asphalt driveways are a budget-friendly option for accommodating heavy vehicles, with lower installation costs compared to concrete. However, it’s important to be aware that asphalt can soften in high temperatures, which may cause deformation when subjected to heavy loads. Additionally, heavy vehicles exert significant force on asphalt driveways, leading to potential wear and tear over time. To enhance durability, consider the long lifespan of tarmac driveways, which can withstand heavy traffic without cracking. Weighing these factors carefully will help you choose the best material for your driveway.

Cost-Effective Option

Asphalt driveways may attract you with their lower initial installation costs, but it’s important to consider both their pros and cons, particularly for heavy vehicle use.

While asphalt is cheaper to install than concrete, its durability under heavy loads can be an issue. Properly laid asphalt can handle vehicles up to 20,000 pounds, but frequent heavy use can result in rutting and surface damage over time. Additionally, asphalt driveways typically last about 15-20 years compared to concrete’s longer lifespan.

Regular maintenance, such as sealing and crack repairs, is essential to prolong asphalt’s lifespan. Additionally, a strong base and a thickness of 40mm to 60mm are crucial for optimal performance.

If you’re focused on upfront costs, asphalt might seem appealing, but it’s wise to think about the long-term effects, especially for heavy vehicles.

Temperature Sensitivity Issues

Asphalt driveways face significant temperature changes that can affect their performance, particularly under heavy vehicles.

In hot weather, asphalt softens, losing rigidity and becoming prone to deformation, such as ruts. This compromises the surface and often leads to more frequent maintenance.

In colder conditions, asphalt contracts, creating tension that can cause cracks as temperatures fluctuate. The cycle of expansion and contraction, particularly with heavy loads, speeds up wear. Understanding the effects of asphalt’s reaction to different climates can help in selecting the right materials for your driveway.

To address these challenges, consider using heat-resistant asphalt mixes or polymer-modified asphalt. These options can improve resilience to temperature extremes, helping to prolong the life of your driveway.

Concrete Driveways: Strength and Longevity

When choosing a driveway material for heavy vehicles, concrete is a standout option thanks to its remarkable strength and durability. Its robust qualities make it perfect for supporting substantial loads.

For residential use, a compressive strength of 3,000-4,000 PSI is typical.

For heavy-duty applications, aim for 5,000 PSI or above.

Designs should be thicker, around 5 to 6 inches, if you expect frequent use by heavy vehicles.

Adding steel reinforcement can improve durability and minimise cracking.

Proper preparation of the base is crucial for long-lasting stability.

Interlocking Pavers: Aesthetic and Functional Benefits

Concrete driveways are known for their strength, but interlocking pavers provide a strong alternative that balances style with practicality.

These pavers have a high load-bearing capacity, making them suitable for heavy vehicles like vans and 4x4s without the risk of cracking. Their modular design allows for flexibility during freeze/thaw cycles, enhancing their durability.

Aesthetically, interlocking pavers are available in various shapes, sizes, and colours, enabling you to customise your driveway to complement your home’s architecture.

If a paver gets damaged, it can be easily replaced, ensuring minimal disruption and cost-effective maintenance.

With their stain resistance and low upkeep, interlocking pavers offer a blend of functionality and visual appeal, significantly enhancing your property’s value and curb appeal.

Comparing Maintenance Needs of Driveway Materials

When choosing a driveway material, it’s important to consider the maintenance needs of each option. Different materials require varying levels of upkeep, which can affect your routine.

- Asphalt: Needs sealing every 2–3 years to protect it.

- Concrete: Requires occasional cleaning and sealing, depending on how much it’s used.

- Block Paving: Individual blocks can be easily replaced, making repairs straightforward.

- Tarmac: Regular sealing is necessary to keep the surface in good condition.

- Climate Effects: Weather conditions can influence how often you need to seal and maintain your driveway.

Being aware of these factors will help you choose a material that suits your maintenance preferences and can handle the demands of heavy vehicles. Additionally, tarmac driveways, when properly installed, can last 20 to 30 years with minimal upkeep, making them a durable choice for heavy traffic.

Keeping up with maintenance not only extends the life of your driveway but also helps avoid expensive repairs in the future.

Cost Considerations for Heavy Vehicle Driveways

Choosing the right driveway material for heavy vehicles is crucial, particularly when considering both maintenance and costs. Durability is a key factor in this decision.

In the UK, asphalt typically costs between £30 to £60 per square metre, while concrete ranges from £40 to £80. Although concrete requires a higher initial investment, its lifespan of 20-30 years compared to asphalt’s 10-20 years can lead to substantial savings over time.

Installation costs can vary depending on your location and the labour involved, so it’s important to budget accurately.

Opting for high-quality materials like concrete may also increase your property’s resale value, making the initial costs more justifiable down the line.

Climate and Its Impact on Driveway Material Selection

When choosing driveway materials, it’s essential to consider how temperature changes affect their performance.

For example, extreme heat or cold can cause materials to expand and contract, impacting their durability.

Furthermore, the freeze-thaw cycles common in the UK can cause serious damage to certain materials, so it’s important to assess your local climate carefully.

Temperature Effects on Materials

Understanding how temperature affects driveway materials is crucial for ensuring optimal performance, particularly for heavy vehicles. The way materials react to temperature changes can significantly influence their longevity and flexibility.

- Concrete reflects sunlight, keeping surfaces cooler than asphalt during hot weather.

- Asphalt tends to soften in high temperatures, making it susceptible to deformation under heavy loads.

- Rubber pavers, although flexible, can reach temperatures of 77°C (170°F) and may not adequately support heavy vehicles.

- Proper installation of concrete is vital to prevent cracking in extreme conditions.

- Asphalt is generally easier to repair than concrete, making it a practical choice for addressing temperature-related wear.

When choosing materials, it’s important to consider these temperature effects to ensure durability and performance for heavy vehicles.

Freeze-Thaw Considerations

As temperatures vary, the effects of freeze-thaw cycles on driveway materials become crucial for ensuring durability, especially with heavy vehicles.

These cycles can cause significant damage to asphalt and concrete, leading to cracks and potholes. Therefore, it’s important to choose materials that can withstand these conditions.

Porous pavers like Grasspave2 and Gravelpave2 are beneficial as they allow water to drain, reducing the risk of freeze-thaw damage.

Opting for resilient materials not only lowers maintenance costs but also extends the life of your driveway.

In areas prone to freeze-thaw cycles, investing in durable options is vital for long-term performance, making careful material selection essential for maintaining structural integrity in challenging weather.

Frequently Asked Questions

Can I Install Heavy Vehicle Driveways Myself?

You can try installing a heavy vehicle driveway yourself, but it’s important to weigh your skills, the equipment you’ll need, and the safety risks involved. For instance, if you’re not familiar with proper groundwork or drainage, it might be wise to seek help. Selecting the right materials is crucial, as heavy vehicles can significantly affect the driveway’s durability and maintenance over time. Remember, a well-prepared base is key to avoiding future issues.

What Is the Best Driveway Material for Extreme Climates?

When selecting driveway materials for extreme climates, it’s essential to consider performance in cold weather and heat resistance. In colder regions, asphalt is a strong choice due to its ability to withstand freezing temperatures. Conversely, concrete is better for hotter climates, but it does require regular sealing to maintain its durability. Assess your local climate to ensure you choose the most suitable material for your driveway.

How Does Drainage Affect Driveway Material Choice?

When choosing materials for your driveway, it’s essential to consider how drainage will affect its durability. Proper drainage helps prevent water pooling, which can lead to damage over time. Opt for materials that work well with drainage systems, like permeable block paving or gravel, to enhance the driveway’s lifespan and reduce maintenance. This not only keeps your driveway looking good but also saves you time and money in the long run.

Are There Eco-Friendly Options for Heavy Vehicle Driveways?

Eco-friendly options for heavy vehicle driveways include recycled asphalt and permeable concrete. These materials can withstand heavy loads while improving drainage and minimising environmental impact. For instance, using recycled asphalt not only repurposes waste but also offers a durable surface. Permeable concrete allows rainwater to seep through, reducing surface runoff and helping to manage water resources effectively.

How Often Should I Replace My Driveway Material?

You should replace your driveway material based on its lifespan and durability. Concrete can last between 25 to 50 years, while asphalt generally lasts around 20 years. Regular maintenance, such as sealing cracks and cleaning, can significantly extend its life and delay the need for replacement. For instance, a well-maintained asphalt driveway could last longer than the average if cared for properly.

Conclusion

When selecting the best driveway material for heavy vehicles, consider durability, maintenance, and cost. Asphalt is flexible and can withstand heavy loads, while concrete offers superior strength. Interlocking pavers can enhance visual appeal, but their ability to support heavy vehicles may be questionable.

Additionally, think about your local climate, as it can affect the lifespan of the material. A poor choice could lead to expensive repairs in the future. Choose wisely; the right material can significantly impact your driveway’s performance and longevity.

Beneath the surface of tarmac and asphalt driveways lies a world of differences; discover which option suits your needs best.

Choosing between a tarmac and resin driveway can be challenging; discover the key factors that could influence your decision.

Tarmac driveways can support impressive weights, but understanding the key factors will help you determine just how much yours can Read more