Yes, resin driveways can crack due to factors like poor installation, environmental conditions, and inadequate base preparation. To prevent this, ensure a solid base, mix resin and aggregate properly, and avoid installation during extreme weather. Regularly inspect your driveway for early signs of hairline cracks, which can be repaired with the right materials. If cracks exceed 3mm or develop patterns, it’s best to consult professionals for repairs. For more tips on maintaining your driveway, feel free to reach out.

Table of Contents

ToggleKey Takeaways

Yes, resin driveways can crack. This often happens due to an unstable base, poor installation, or environmental issues like freeze-thaw cycles.

To prevent cracking, it’s essential to prepare the base properly and avoid laying the resin in extreme weather. Regular inspections can help you spot hairline cracks early, allowing for quick repairs before they escalate.

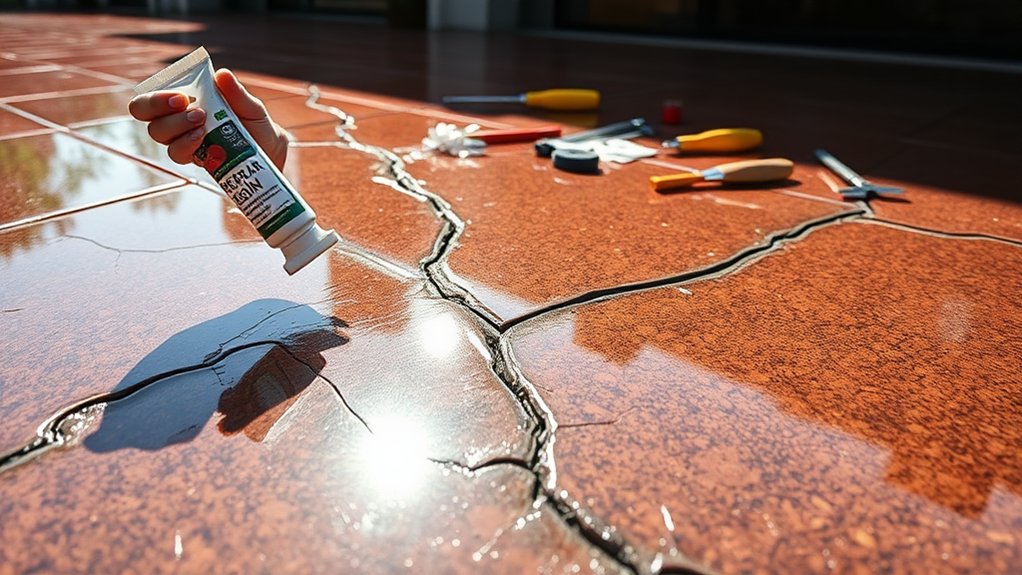

For minor hairline cracks, clean the area thoroughly and fill it with the right crack filler, following the provided curing instructions. If you notice cracks wider than 3mm, spiderweb patterns, or signs of significant water infiltration, it’s best to consult a professional.

Understanding the Causes of Cracking in Resin Driveways

When considering the durability of resin driveways, it’s important to recognise that cracking often arises from issues with the base or sub-base. A stable base is crucial; if the preparation is inadequate, it can lead to movement and stress on the resin layer. For example, if the base material isn’t compacted properly, it may settle unevenly, causing cracks. Additionally, using the wrong aggregates, such as those high in iron content, can lead to rust spots and eventual cracking. Poor installation practices can further exacerbate these problems. To ensure your resin driveway lasts, prioritise proper base preparation, select the right aggregates, and hire skilled installers to reduce the risk of cracking. Proper maintenance can also mitigate many common problems that may arise over time. Regular inspections can help identify potential issues before they escalate into more significant problems.

Environmental Factors That Affect Resin Driveways

When assessing the durability of your resin driveway, it’s important to consider freeze-thaw cycles and humidity levels. These factors can cause the material to expand and contract, which may lead to cracking if the installation isn’t done correctly. For instance, heavy rainfall followed by a drop in temperature can create conditions that strain the surface. Additionally, the permeability of resin driveways helps mitigate water accumulation, reducing the risk of damage from freeze-thaw cycles. Ensuring a solid, crack-free sub-base is essential to prevent potential cracking issues in the future.

Freeze-thaw Cycles Impact

Freeze-thaw cycles pose a significant challenge to resin driveways, and it’s crucial to understand their effects on structural integrity. These cycles can compromise the material by allowing water to seep into small cracks, which then expand when frozen. Here’s a summary of the main effects:

| Effect | Description |

|---|---|

| Water Infiltration | Water enters cracks during warmer periods. |

| Pressure Build-Up | Ice expands, increasing pressure and exacerbating cracks. |

| Thermal Expansion/Contraction | Fluctuating temperatures cause movement in the surface. |

| Material Weakening | Repeated cycles diminish the toughness and strength of the resin. |

To reduce the impact of freeze-thaw cycles, ensure proper drainage, seal any cracks, and choose durable resin mixes during installation. This proactive approach will help maintain the longevity and appearance of your driveway, especially considering proper drainage systems are crucial for preventing water accumulation. Implementing SuDS (Sustainable Urban Drainage Systems) can further enhance your driveway’s resilience to environmental factors.

Humidity and Moisture Effects

Humidity and moisture significantly affect the performance of resin driveways, influencing both installation and long-term durability. High humidity can change catalyst requirements and extend curing times, leading to uneven surfaces and a cloudy finish.

It affects how well the resin bonds with stones, which can compromise the driveway’s strength. Moreover, moisture during curing can cause aesthetic issues like white patches and gas bubbles, weakening the surface.

To avoid these problems, always check humidity levels before installation, aiming for conditions below 87%.

Ensure there’s a 24-hour rain-free period after installation to prevent moisture-related damage. If rain is forecast unexpectedly, using tarpaulins can help protect the area and maintain the integrity of your resin driveway.

Common Installation Errors Leading to Cracking

Improper installation practices can seriously undermine the lifespan and strength of resin driveways, often leading to unsightly cracks. Key issues stem from poor material choices and inadequate installation techniques. Here’s a quick overview:

| Common Errors | Consequences | Prevention Tips |

|---|---|---|

| Poor sub-base preparation | Unstable foundation causing cracks | Excavate and compact properly |

| Incorrect mix proportions | Weak bonding | Keep the right resin-to-aggregate ratio |

| Surface application mistakes | Vulnerable points prone to cracking | Apply evenly and clear debris |

| No expansion provision | Internal stress leading to damage | Install expansion joints |

Identifying Different Types of Cracks in Resin Driveways

Understanding common installation errors is key to preventing cracks in resin driveways, but it’s equally important to identify the types of cracks that can occur.

Base-related cracks often indicate instability beneath the surface, which can affect the overall look of your driveway.

Surface or shrinkage cracks are usually cosmetic, caused by improper curing or thin layers, but they can lead to water ingress if ignored.

Impact or pressure cracks happen from heavy loads or sharp objects and require targeted repairs.

Structural or slab edge cracks arise from uneven support and can worsen if not addressed.

Lastly, weather-related cracks, influenced by freeze-thaw cycles and UV exposure, need regular upkeep to prevent further damage.

Using effective crack repair methods is essential for maintaining your driveway’s integrity and appearance.

Preventative Measures to Avoid Cracking

To minimise the risk of cracking in your resin driveway, it’s crucial to prioritise preventative measures during installation.

Start with proper base preparation; a level and stable foundation is essential for the longevity of your resin. Keep an eye on the weather—avoid installing in rain or extreme temperatures, as these can compromise the resin’s quality.

Ensure you mix the resin and aggregate according to the recommended ratios to maintain flexibility. Store the resin in cool, shaded places to prevent deterioration.

Adding fibre reinforcement can also enhance strength against ground movement and heavy traffic.

Importance of Proper Base Preparation

The durability of your resin driveway heavily relies on proper base preparation. A stable base is crucial, as it affects both the longevity and overall performance of your driveway. Opt for either porous concrete or tarmac, ensuring that the existing surface is undamaged, clean, and stable. A strong sub-base is also essential for load-bearing support, helping to avert cracks.

Here’s a brief overview of what you need for effective base preparation:

| Element | Importance | Considerations |

|---|---|---|

| Base Type | Ensures permeability | Use porous concrete or tarmac |

| Sub-Base | Provides strength | Ensure adequate depth and compaction |

| Surface Condition | Influences adhesion | Inspect for damage and clean thoroughly |

| Drainage | Prevents waterlogging | Adhere to permeability guidelines |

| Installation Quality | Minimises future problems | Professional installation is recommended |

The Role of Temperature Fluctuations in Cracking

Temperature fluctuations are crucial in the cracking of resin driveways, as the materials expand and contract with heat and cold. These thermal stresses can cause significant problems, particularly during extreme temperatures.

Repeated cycles of expansion and contraction weaken the surface, increasing the likelihood of micro-cracks turning into larger fissures. In hot weather, the resin softens, while cold temperatures make it brittle, reducing flexibility and heightening the risk of cracking.

The freeze-thaw cycle is especially problematic; water that seeps into cracks expands when frozen, creating additional pressure. To combat these issues, proper drainage and regular maintenance are vital to keep your driveway resilient against temperature changes.

Repairing Hairline Cracks: DIY Solutions

To effectively repair hairline cracks, start by pinpointing their location on your driveway.

Clean the area thoroughly to ensure the crack filler adheres properly.

Then, apply the recommended filler according to the manufacturer’s instructions for the best outcome.

Identify Hairline Crack Location

How can you effectively locate hairline cracks in your resin driveway? Start by inspecting the surface closely, paying attention to thin, narrow cracks that are usually less than 1.5mm wide.

Use a magnifying glass to spot fine stress lines that may be tricky to see. Focus on areas near edges, joints, or spots prone to ground movement.

Additionally, shining a torch at a low angle during early morning or late evening can help highlight subtle cracks.

Identifying these cracks early is vital to prevent further damage, allowing you to tackle issues before they develop into larger problems.

Regular checks will help keep your driveway in top condition.

Clean and Prepare Surface

After identifying hairline cracks in your resin driveway, the next step is to clean and prepare the surface for repair.

Start by thoroughly cleaning the area; use a wire brush to remove loose debris and dirt around the crack. A pressure washer is effective for eliminating oil stains and grime. For stubborn debris, use compressed air to blow it out of the crack.

Apply degreasers on any oily spots to ensure proper adhesion. Prepare the surface by removing any loose concrete around the edges and ensure it’s dry. Use a putty knife to smooth the area, slightly overfilling the crack with filler to account for shrinkage.

Mask off surrounding areas to prevent material spread, and allow the surface to dry completely before proceeding with repairs.

Apply Crack Filler

Start by choosing the right crack filler for your resin driveway, as this significantly affects the repair’s success. For hairline cracks, epoxy injection systems or specialised resin mixtures work best.

Clean the cracks by removing debris and using a nylon bristle brush. For deeper cracks, insert backer rods for added support.

When applying the filler, use a caulking gun for precision. Press the filler firmly into the crack with a putty knife or trowel, slightly overfilling to allow for shrinkage.

Let the first layer cure before applying any sealant. Always refer to the manufacturer’s instructions for specific curing times, ensuring the filled area remains undisturbed until fully set for lasting durability.

When to Seek Professional Help for Larger Cracks

Knowing when to call in a professional for larger cracks in your resin driveway is crucial to prevent further damage and ensure safety. If you spot cracks wider than 3mm (0.125 inches), a spiderweb pattern, or signs of water infiltration, it’s time to seek an expert assessment. Additionally, if cracks are growing over time or appear suddenly after severe weather, they require immediate attention. Professionals can use methods like epoxy resin injection or crack stitching to effectively tackle these issues.

| Crack Type | Signs of Concern | Recommended Action |

|---|---|---|

| Structural Cracks | Wider than 3mm (0.125 inches) | Expert evaluation |

| Network Cracks | Spiderweb pattern | Advanced diagnostics |

| Water Penetration | Allowing weeds or water | Professional repair methods |

| Large Fissures | Sudden appearance after events | Urgent professional help |

Maintenance Tips for Extending the Lifespan of Your Resin Driveway

To extend the lifespan of your resin driveway, set up a regular cleaning routine to clear away debris and prevent moisture build-up.

If you spot any cracks, address them straight away; ignoring minor damage can lead to bigger problems later on.

Regular Cleaning Schedule

A regular cleaning schedule is essential for keeping your resin driveway looking its best and lasting longer. Regular cleaning helps prevent the accumulation of debris that can cause damage. Here’s a quick reference table to help you with your maintenance routine:

| Cleaning Task | Frequency |

|---|---|

| Sweeping | Weekly |

| Raking (for heavy debris) | As needed |

| Washing (using a gentle detergent) | 3-4 times a year |

| Pressure Washing | As necessary (low pressure) |

Use manual sweeping, leaf blowers, and raking to effectively remove debris. For optimal results, combine sweeping with washing. Tackle any stains or weed growth promptly to protect your driveway’s integrity. This proactive approach will ensure your resin driveway remains in excellent condition for years to come.

Prompt Crack Repairs

Regular inspections and prompt repairs of cracks in your resin driveway are crucial for prolonging its life and maintaining its appearance. Detecting cracks early lets you evaluate their size and depth, helping you choose the right repair method.

Start by thoroughly cleaning the area to remove any debris and ensure your repair materials, such as epoxy or polyurethane fillers, are compatible.

When preparing for repairs, slightly widen the cracks and mix the resin fillers with a forced action mixer for a uniform consistency. After applying the filler, smooth the edges with a trowel, and consider using a heat gun to blend the materials effectively.

Finally, applying a protective sealant will enhance durability and help prevent further damage. By following these steps, you’ll significantly aid in crack prevention and improve the longevity of your driveway.

Frequently Asked Questions

How Long Does a Resin Driveway Typically Last Before Needing Repairs?

Did you know that a well-maintained resin driveway can last over 25 years? To ensure this longevity, it’s important to carry out regular maintenance, such as cleaning and resealing every 3 to 5 years. This simple routine can help you avoid costly repairs down the line.

Can I Install a Resin Driveway Myself, or Should I Hire a Professional?

You can opt for a DIY installation to save money and personalise your resin driveway, but hiring a professional ensures accurate application and long-lasting results. Consider your skills and available time against the potential pitfalls. For instance, if you’re unsure about mixing resin or laying it evenly, it might be wise to leave it to the experts. Make your decision based on what suits your needs best.

What Colors and Designs Are Available for Resin Driveways?

Resin driveways offer a wide range of colour options and design patterns, from natural earthy tones to vibrant shades. This variety allows you to create a personalised look that suits your home. For example, you might choose a warm terracotta for a rustic feel or a striking blue for a contemporary touch. The choices are vast, making it easy to find the perfect match for your style.

How Does the Cost of Resin Driveways Compare to Traditional Paving?

When comparing costs, resin driveways have distinct advantages. Although they may be more expensive initially than traditional paving, their durability and minimal maintenance can result in savings over time. For many homeowners, this makes them a sensible investment. For example, a resin driveway can last significantly longer than block paving, reducing the need for repairs and replacement.

Are Resin Driveways Environmentally Friendly and Sustainable Options?

Resin driveways are a sustainable choice for your home. They use eco-friendly materials and support water management due to their permeability. Additionally, incorporating recycled aggregates helps minimise environmental impact, making them a great option for urban living.

Conclusion

To keep your resin driveway crack-free, think of it like tending to a garden; it needs regular care. Understanding what causes cracks and taking preventative steps can safeguard your investment from weather damage and poor installation. Routine maintenance and swift repairs are key to avoiding cracks, ensuring your driveway stays a lovely and sturdy surface for years to come. Don’t wait for cracks to appear—take action beforehand!

Whilst it is true that there are certain conditions required in order to lay a resin bound stone patio, pathway Read more

If your driveway is looking old and tired, a new one can help revamp your property. Modern driveways are available Read more

APPROVED RESIN BOUND DRIVEWAY INSTALLERS LOCAL TO YOU! Find out More Get in Touch Get a Free Quote Book an Read more