When it comes to slip resistance, tarmac driveways generally outperform resin options, especially in wet conditions. Tarmac’s high-friction material and textured surface provide a reliable grip, making it a safer choice during rain. In contrast, resin surfaces can vary in effectiveness depending on the type and texture of the aggregate used, which may lead to less traction when wet.

It’s important to remember that regular maintenance is vital for both materials to maintain their skid resistance. By looking into the pros and cons of each driveway type, you can make a more informed decision about which is best for your needs.

Table of Contents

ToggleKey Takeaways

- Tarmac generally offers good grip in dry conditions but can become slippery when wet due to a film of water.

- Resin driveways tend to provide better slip resistance in wet weather, depending on the type of aggregate used.

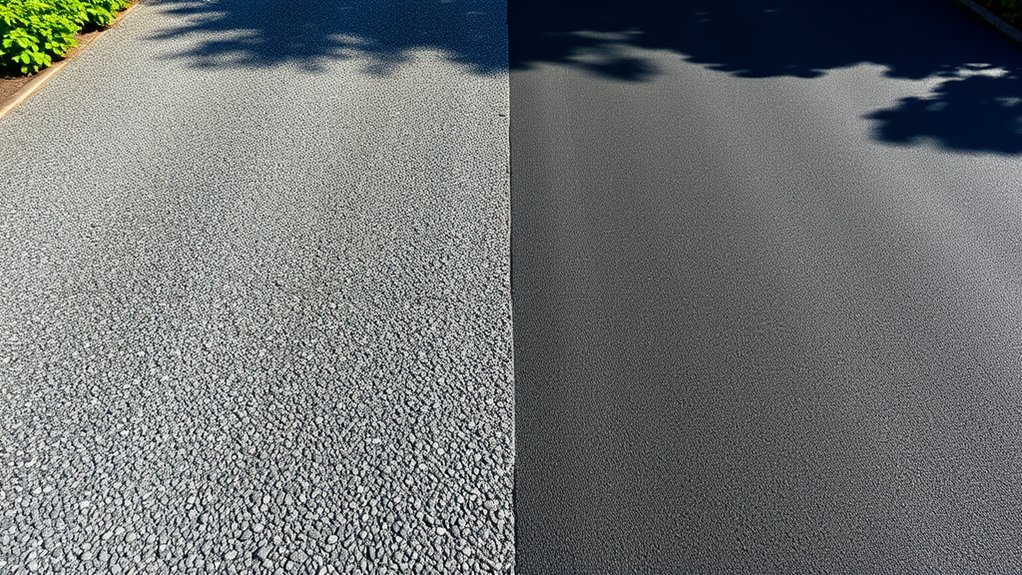

- Tarmac features a textured surface that improves traction, whereas resin surfaces depend on the texture of the aggregate for skid resistance.

- Both surfaces require regular maintenance, but resin may need resealing less frequently to keep its slip resistance intact.

- Tarmac is easier and more affordable to repair, while resin repairs often need professional help and specialised materials.

Overview of Tarmac and Resin Driveways

When choosing a driveway, it’s important to weigh the benefits of tarmac and resin options.

Tarmac driveways are known for their durability, lower installation costs, and low maintenance. Their textured surface provides good slip resistance, making them a safe option in wet weather. Additionally, tarmac can be enhanced with high friction features to further improve safety in high-risk areas. Tarmac driveways also have a lifespan of 15 to 20 years with proper maintenance, ensuring long-term value.

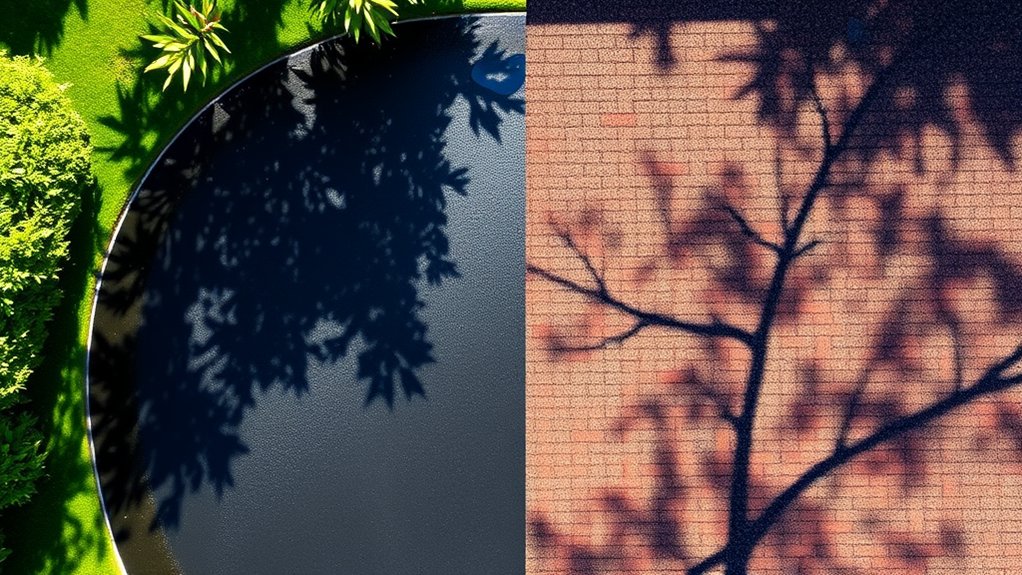

In contrast, resin driveways excel in aesthetics, offering a variety of colours and finishes to boost your home’s appeal. While you can enhance their slip resistance with added aggregates, resin tends to have higher installation costs and may need more upkeep over time.

Ultimately, your decision should reflect your priorities concerning budget, safety, and appearance.

Composition and Material Properties

Tarmac and resin driveways both serve their purpose well, but their materials affect their performance and longevity.

Tarmac is made from crushed stone combined with tar or bitumen, which provides strong binding and flexibility. This makes it durable enough to handle heavy traffic and tough weather, contributing to its durability and longevity.

On the other hand, resin driveways consist of a resin and aggregate mix, where the resin acts as the binding agent. This type offers various aesthetic options and can be eco-friendly, but it may degrade under UV light over time.

Understanding these differences can help you choose the best driveway option for your needs.

Skid Resistance Capabilities

Skid resistance is essential for ensuring safety and performance on driveways, especially in varying weather conditions. To gauge skid resistance, tools like the British Pendulum Number (BPN) are used, which measures the force when a tyre slides on a surface. Tarmac generally meets specific skid resistance standards due to its high-friction materials, making it a better choice for high-risk areas. On the other hand, resin driveways have less documented skid resistance, as it largely relies on the texture of the aggregate used. While resin can be more durable, its skid resistance may not always meet standards without appropriate texture and regular maintenance. Understanding these differences will help you choose the right material for safety, as skid resistance is influenced by both pavement microtexture and macrotexture. Additionally, incorporating eco-friendly materials in resin driveways can enhance performance while minimizing environmental impact.

Impact of Surface Weathering on Skid Resistance

Weathering significantly affects the skid resistance of both tarmac and resin surfaces.

Tarmac tends to deteriorate more quickly, suffering from cracking and the exposure of aggregate. In contrast, resin surfaces hold up better but still need careful management regarding moisture and temperature.

Regular maintenance and timely repairs are crucial for maintaining skid resistance in both types of surfaces, ensuring safety over time. Implementing regular inspections can help identify potential issues early, further enhancing the longevity and safety of the driveway.

Weathering Effects on Surfaces

As surfaces weather over time, their slip resistance can change significantly, affecting safety and usability.

Tarmac, for instance, can suffer from loose stones and erosion, which reduces its durability.

On the other hand, resin driveways are more resilient due to their flexible properties, resisting cracking and adapting to ground movements.

This adaptability ensures consistent slip resistance, regardless of temperature or weather conditions.

Additionally, resin is UV resistant, helping to maintain its smooth texture for longer.

Therefore, while tarmac may become slippery due to environmental wear, resin surfaces offer a durable, slip-resistant alternative that endures the test of time.

Maintenance and Repair Needs

Maintaining your driveway may seem trivial, but neglecting it can lead to reduced skid resistance over time.

Regular care ensures the surface remains safe and sound. Here are some key maintenance tips:

- Cleaning Routine: Regularly sweep and pressure wash to keep it tidy.

- Sealcoating: Apply a sealant every few years to enhance durability.

- Weed Control: Use barriers or appropriate weed killers to stop unwanted growth.

- Timely Repairs: Fix cracks and potholes as soon as they appear using suitable materials.

- Expert Help: For more complex repairs, it’s wise to consult professionals.

Maintenance Requirements for Skid Resistance

To ensure optimal skid resistance, regular maintenance is crucial.

For resin driveways, you should reseal periodically to maintain the textured surface that provides grip.

Tarmac, on the other hand, needs careful attention to its surface texture and timely sealing to avert slipping hazards.

Regular checks and maintenance will help keep your drive safe.

Regular Re-Sealing Necessity

Regular resealing is vital for keeping tarmac and resin driveways skid-resistant, ensuring they remain safe and functional. Here are some straightforward maintenance tips:

- Reseal tarmac every 2 to 3 years to avoid surface wear.

- For resin driveways, adjust the resealing frequency based on how often they’re used and their exposure to sunlight.

- Conduct yearly inspections to determine if resealing is necessary.

- Quickly address any wear from weather or vehicle traffic.

- Aim to reseal during warmer months for the best results.

Regular resealing helps restore protective coatings, fills in any gaps, and improves grip.

If neglected, the risk of slipping increases, making routine resealing a crucial part of driveway upkeep.

Surface Texture Maintenance

Maintaining the surface texture of your driveway is crucial for ensuring good skid resistance. When choosing a driveway, it’s important to know that both tarmac and resin need regular upkeep to keep their textures intact.

For tarmac, routine cleaning and prompt crack repairs are key; applying surface dressing can also boost skid resistance.

Resin driveways, which are generally smoother, benefit from adding aggregates and using anti-slip coatings to improve grip. Regular checks can help spot any surface wear, which can impact traction over time.

Additionally, proper drainage is vital for both types, as standing water can reduce grip. By staying on top of these maintenance tasks, you’ll improve your driveway’s durability and safety.

Aggregate Effects on Skid Resistance

When assessing how aggregate affects skid resistance, it’s essential to look at the various characteristics of aggregates and their impact on pavement performance.

Different types of aggregates significantly influence skid resistance through several key factors:

- Mineral Composition: This affects the wear-resistance of the surface.

- Angular and Textural Properties: Aggregates with higher angularity and texture improve surface roughness, which enhances grip.

- Polishing Resistance: Aggregates that resist polishing maintain their skid resistance even under heavy traffic.

- Aggregate Gradation: The right gradation is crucial as it determines the contact area between tyres and pavement.

- Rock Composition: Differences in rock types can affect friction performance.

Testing Methods for Evaluating Skid Resistance

Understanding how aggregates affect skid resistance is essential for assessing different testing methods. Several techniques exist to measure friction, including both dynamic and static approaches. Dynamic methods mimic real-world conditions, whereas static methods, such as the British Pendulum Tester, operate in controlled environments.

| Testing Technique | Description |

|---|---|

| Locked Wheel Tester | Measures friction by skidding a locked wheel. |

| Spin Up Tester | Spins the wheel before braking to reduce wear. |

| British Pendulum Tester | Best for measuring static friction. |

| Dynamic Skid Devices | Evaluate tyre-pavement interaction in real-time. |

Each method offers valuable insights into skid resistance, helping you choose effectively between tarmac and resin surfaces.

Environmental Conditions and Their Influence

Environmental conditions significantly affect the slip resistance of driveway surfaces, including tarmac and resin. Key factors include moisture and temperature changes, which are crucial for traction.

- Wet surfaces usually decrease slip resistance due to the formation of a water film.

- Resin-bound driveways might offer better grip when wet, but this depends on the type of aggregate used.

- Tarmac’s micro-texture generally provides better traction in rainy conditions, especially when modified with polymers.

- High humidity and debris can make tarmac more slippery.

- Temperature changes can impact skid resistance; colder weather tends to increase friction.

Being aware of these factors helps you maintain a safe driveway, ensuring reliable slip resistance throughout the year.

Repairability and Longevity Considerations

When it comes to keeping your driveway safe and looking good, it’s essential to think about both repairability and longevity.

Tarmac driveways are a cost-effective choice, as you can easily find materials for DIY repairs or hire a professional. They typically last between 15 to 25 years, but they do need regular maintenance to maximise their lifespan.

On the other hand, resin driveways are known for their durability, lasting around 20 to 30 years. However, they can be more complicated to repair. You often need specialised materials, and it’s advisable to get a professional in, which can make repairs slower and pricier. Additionally, matching the aesthetics of the resin can be tricky.

Both driveway types require cleaning, but tarmac needs sealing more frequently, which is something to consider in your maintenance plan.

Weigh your options carefully based on your needs and budget.

Summary of Key Differences in Slip Resistance

When comparing tarmac and resin driveways, their slip resistance differs quite a bit due to the materials and design involved. Here’s a quick overview:

- Tarmac: Offers good grip in dry conditions, but its slip resistance decreases when wet.

- Resin: Features a naturally textured surface that enhances slip resistance, remaining effective even in wet weather.

- Aggregate Selection: Tarmac usually uses limestone or granite, whereas resin can incorporate a variety of aggregates to maximise grip.

- Durability: Resin tends to keep its slip-resistant properties longer than tarmac, which needs regular upkeep.

- Performance Treatments: Tarmac may require treatments like ULTIGRIP to boost skid resistance, whereas resin can benefit from additional coatings for enhanced safety.

Choosing the right option depends on your needs and conditions.

Frequently Asked Questions

How Do Tarmac and Resin Compare in Cost-Effectiveness?

When comparing costs, tarmac usually has lower initial expenses. However, resin can provide better long-term value due to its durability and reduced maintenance needs. This can balance out the higher upfront costs. It’s important to assess your specific requirements and budget to determine which option suits you best. For example, if you have a busy driveway, resin might save you money in the long run despite the initial investment.

Can Tarmac and Resin Be Installed Over Existing Surfaces?

When it comes to installing tarmac or resin, both can be applied over existing surfaces, but proper preparation is key. For tarmac, ensure the base is stable; for resin, the surface must be clean to guarantee good adhesion and longevity.

What Colors and Finishes Are Available for Each Driveway Type?

Tarmac and resin driveways come in various colours and finishes. Tarmac typically offers classic dark shades and earthy tones, such as black, grey, and brown. In contrast, resin driveways present a wider range of colours, allowing for custom patterns and textured aggregates that enhance design options. For example, you might find resin driveways in vibrant shades like red or green, or with decorative finishes that mimic natural stone.

How Do Temperature Fluctuations Affect Tarmac and Resin Driveways?

Temperature fluctuations can significantly affect tarmac driveways, leading to softening in hot weather and brittleness in cold conditions. For example, during a heatwave, tarmac may become soft and prone to damage from vehicle tyres. In contrast, resin driveways offer better stability and durability, remaining resilient regardless of temperature changes. This means they are less likely to crack or become damaged, providing a more reliable surface all year round.

Are There Any Environmental Concerns Associated With Tarmac or Resin?

Tarmac poses environmental issues due to high emissions and potential runoff, while resin can lead to concerns over chemical leaching. It’s wise to explore eco-friendly alternatives that minimise environmental impact, ensuring you make a well-informed choice for your driveway.

Conclusion

In summary, when comparing tarmac and resin driveways for slip resistance, resin surfaces generally outperform tarmac due to their better texture and drainage capabilities. Research indicates that resin-bound driveways can cut slip incidents by as much as 60% compared to traditional tarmac. This notable difference underlines the importance of choosing the right material for safety and durability. By considering these factors, you can make a well-informed decision for your driveway.

How can a tarmac driveway enhance your home's appeal? Discover the key aspects of cost, installation, and maintenance in our Read more

Beneath the surface of tarmac and asphalt driveways lies a world of differences; discover which option suits your needs best.

Uncover the hidden environmental costs of tarmac driveways and explore whether they truly align with sustainable living—what alternatives could be Read more